Control system and crane

A control system and crane technology, applied in cranes, load hanging components, transportation and packaging, etc., can solve problems such as pressure holding, unfavorable vehicle safety control, and affecting hoisting performance, so as to prevent outriggers from holding pressure and supporting Inaccurate detection of leg strength, solve the effect of holding back pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] It should be noted that, in the case of no conflict, the embodiments of the present invention and the features in the embodiments can be combined with each other. The present invention will be described in detail below with reference to the accompanying drawings and examples.

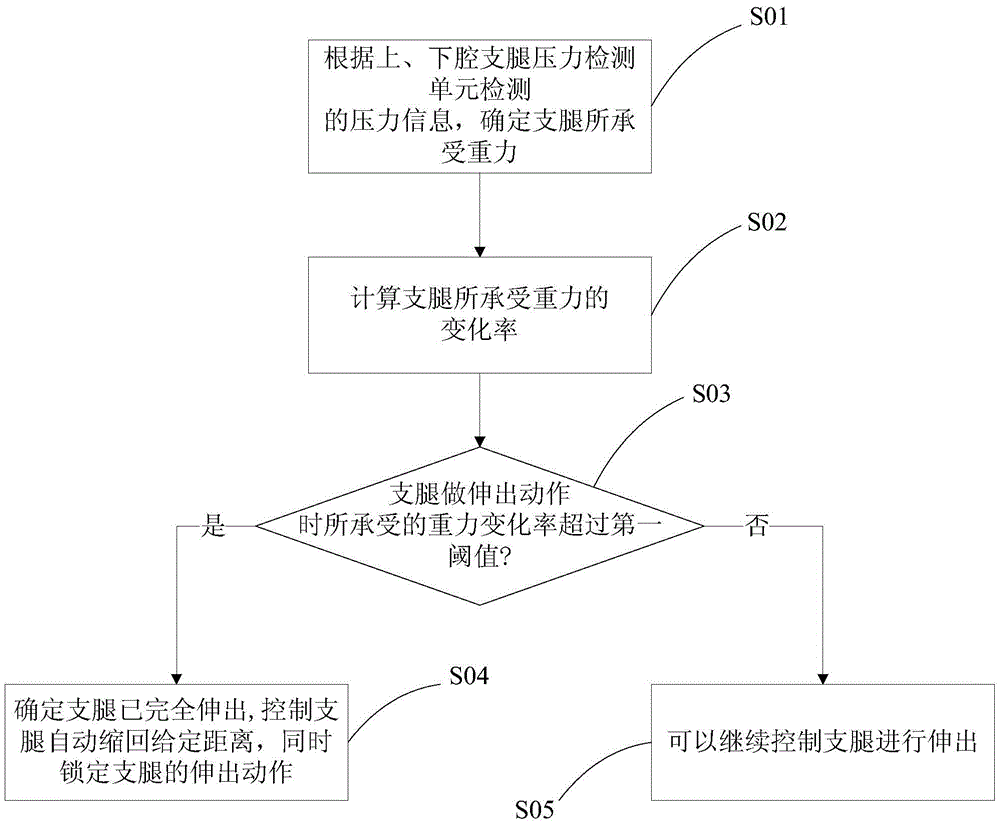

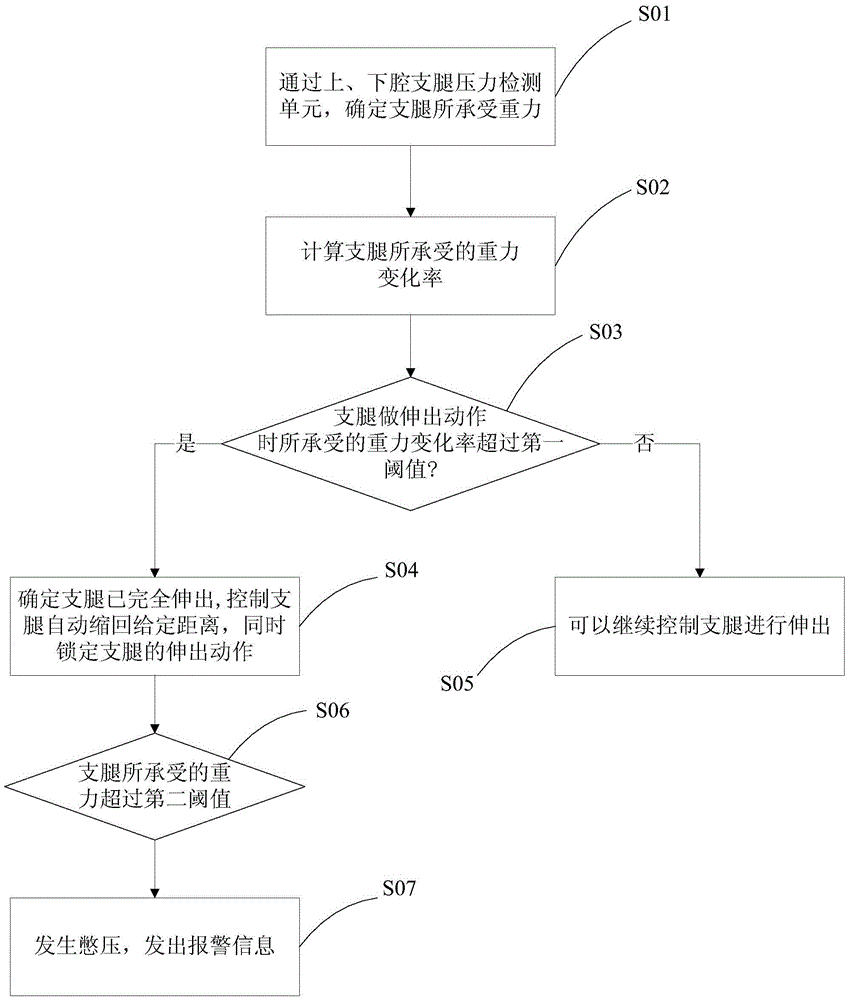

[0031] refer to figure 1 , figure 1 It is a flow chart of the steps of an embodiment of the outrigger telescopic control method of the present invention, the method includes the following steps:

[0032] Step S01: According to the pressure information detected by the outrigger pressure detection unit in the upper and lower chambers, determine the gravity on the outrigger;

[0033] Step S02: Calculate the rate of change of the gravity on the outrigger;

[0034] Step S03: Judging whether the rate of change of the gravity of the outrigger when it is extended exceeds a preset first threshold, and determining that the outrigger has been fully extended; if yes, execute step S04; if not, execute step...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com