Nylon sea-island microfiber leather fabric composite dye and application thereof

A microfiber leather and sea island technology, which is applied in organic dyes, dyeing methods, textiles and papermaking, etc., can solve the problems that restrict the development of sea island microfiber leather, and achieve the effects of easy quality control, good synchronization, and good dyeing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

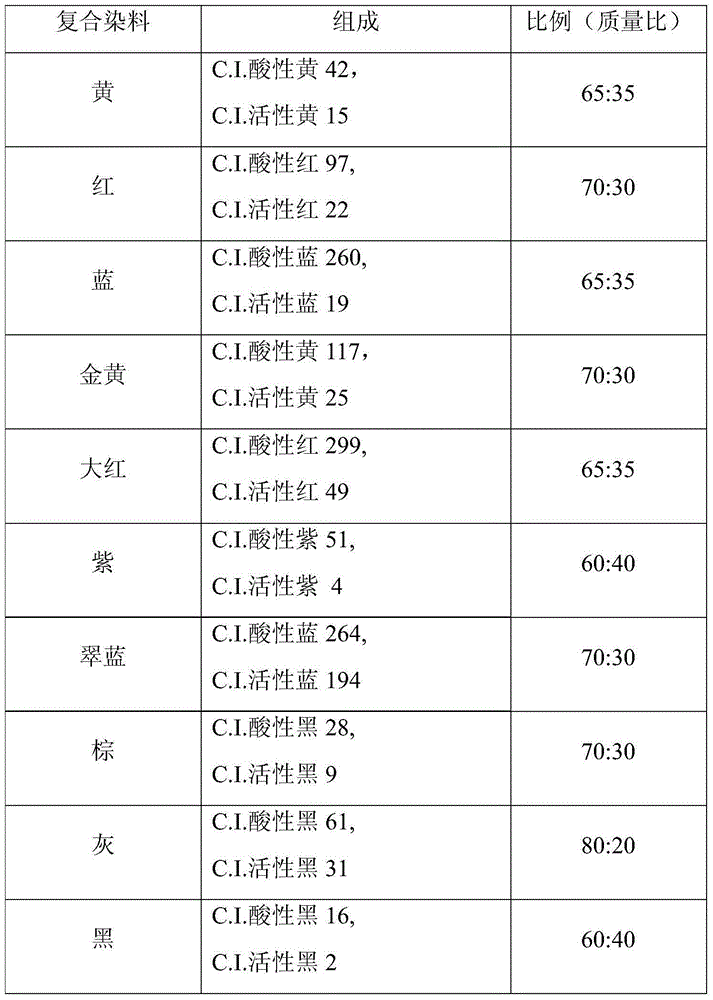

[0028] The composite dyes of different shades are shown in Table 1 below:

[0029]

[0030] Table 1

[0031] The ratio is the mass ratio of acid dye and reactive dye.

Embodiment 2

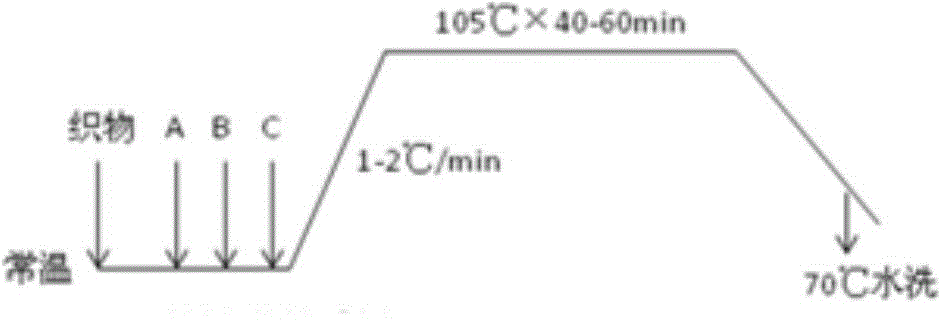

[0033] (1) Dyeing: under normal temperature, PPN acid level dyeing penetrant and composite dye yellow are added to the dyeing bath in sequence, and mixed evenly. Adjust the pH to 5 with the pH adjuster acetic acid to obtain the dye solution, and then immerse the nylon sea-island microfiber leather fabric in the dye solution to heat up The rate is 2°C / min, the temperature is increased to 110°C, kept for 40 minutes, and then the temperature is lowered to 80°C, and the dyed fabric is obtained. The composite dye is dyed with 2% (owf) deep dyeing. The dosage of PPN acid leveling penetrant is 2g / L (relative to the dye bath).

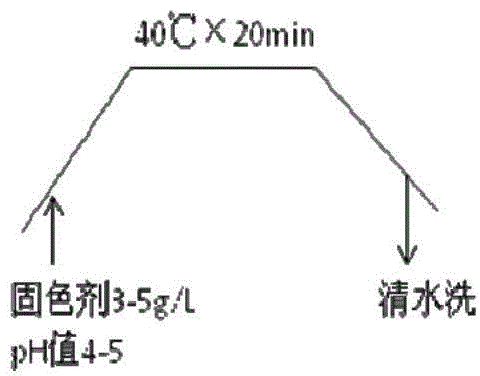

[0034] (2) Fixing: Immerse the dyed fabric in the fixing bath (the amount of fixing agent Cibatex PA is 5g / L, pH=4.5), keep it at 40℃ for 25min, and then wash it with water.

[0035] (3) The resulting color samples were tested for rubbing fastness, see Table 2.

[0036] The composite dye red and composite dye blue of Example 1 were dyed and fixed according to the c...

Embodiment 3

[0038] (1) Dyeing: under normal temperature, PPN acid level dyeing penetrant and composite dye golden color are added to the dyeing bath in turn, mix well, adjust the pH value to 6 with the pH adjuster acetic acid to obtain the dye liquor, and then immerse the nylon sea-island microfiber leather fabric in the dye liquor to heat up The rate is 1℃ / min, the temperature is increased to 105℃, kept for 60min, and then the temperature is lowered to 70℃, and the dyed fabric is obtained. The composite dye is dyed with 0.5% (owf) deep dyeing. The dosage of PPN acid leveling penetrant is 1g / L (relative to the dye bath).

[0039] (2) Fixing: Immerse the dyed fabric in the fixing bath (the amount of fixing agent Cibatex PA is 3g / L, pH=5), keep it at 50℃ for 20min, and then wash it with water.

[0040] (3) The resulting color samples were tested for rubbing fastness, see Table 2.

[0041] The composite dye scarlet, composite dye violet, and composite dye Turquoise blue of Example 1 were respecti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com