Different shrinkage two-component network composite filament

A technology of network compounding and different shrinkage, which is applied in the field of spinning to achieve the effect of uniform dyeing and evenness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

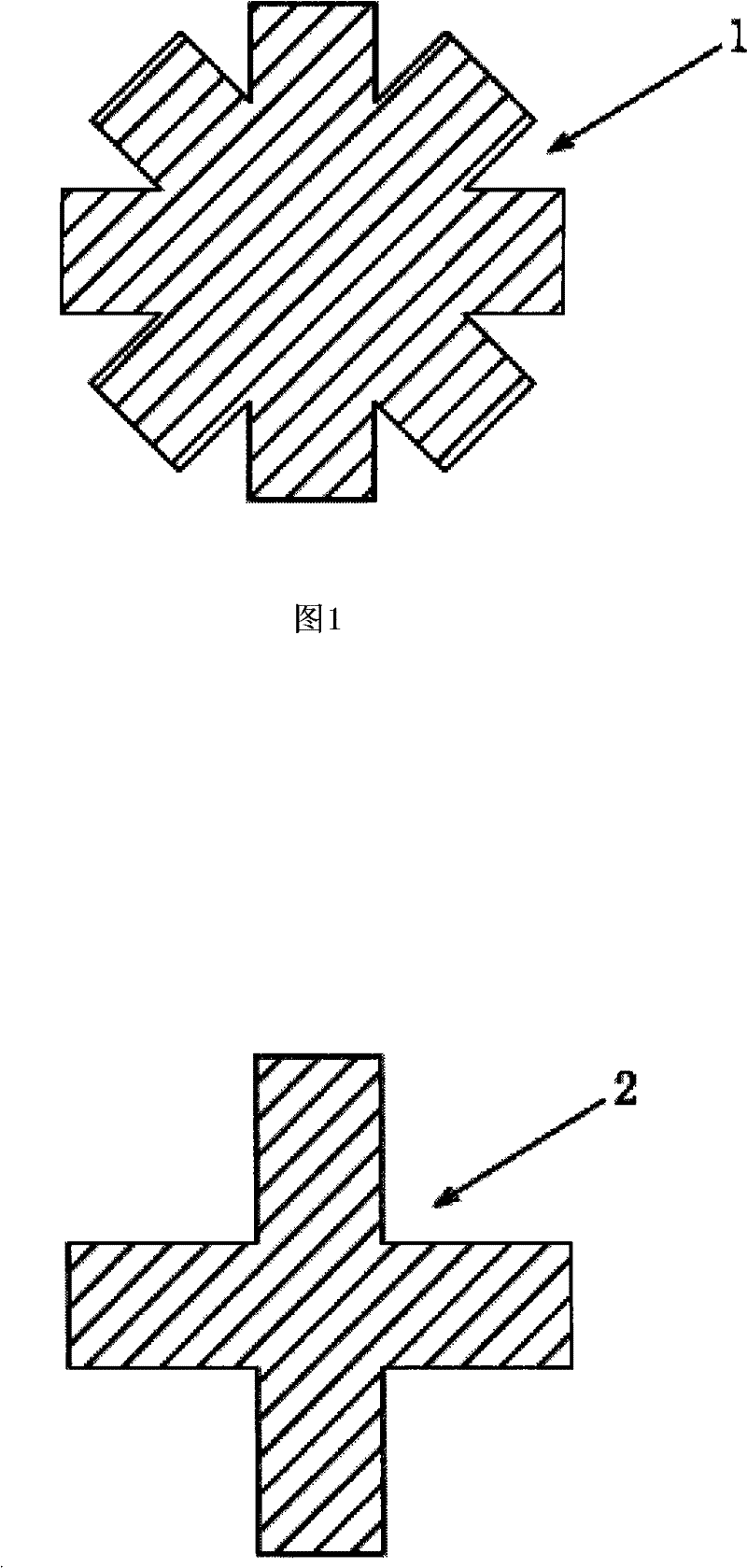

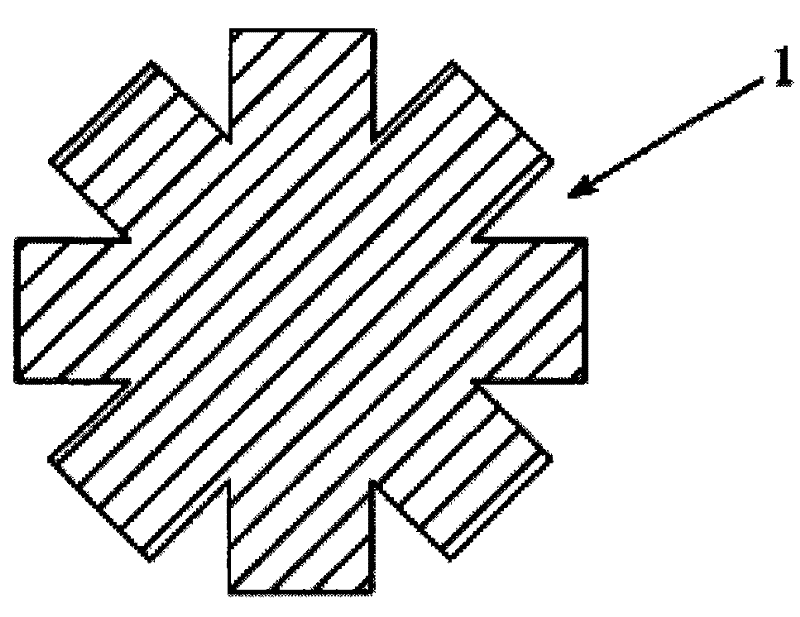

[0009] Embodiment: A kind of different shrinkage two-component network composite yarn, which is composed of pre-oriented yarn 1 and fully drawn yarn 2. The pre-oriented yarn is composed of 8 to 144 filament fibers, and the cross-section of the pre-oriented yarn is It is in the shape of "rice", the fully drawn yarn is composed of 8 to 96 filament fibers, and the cross section of the fully drawn yarn is in the shape of "ten".

[0010] The production process of this example is as follows:

[0011] Pre-oriented yarn POY and fully drawn yarn FDY are obtained by drying raw materials, screw melting, module output, side blowing cooling and godet drawing;

[0012] In the process of producing pre-oriented yarn 1, the components used in the component filament discharge link, the holes on the spinneret are "meter" shaped; in the process of producing fully drawn filament 2, the component used in the component filament discharge link, its The holes on the silk board are in the shape of "te...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com