Patents

Literature

45results about How to "With perspiration" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Production technology for antibiosis moisture exhausting sock

InactiveCN104195735AHas antibacterial propertiesFunctionalFabric breaking/softeningWeft knittingAntibiosisYarn

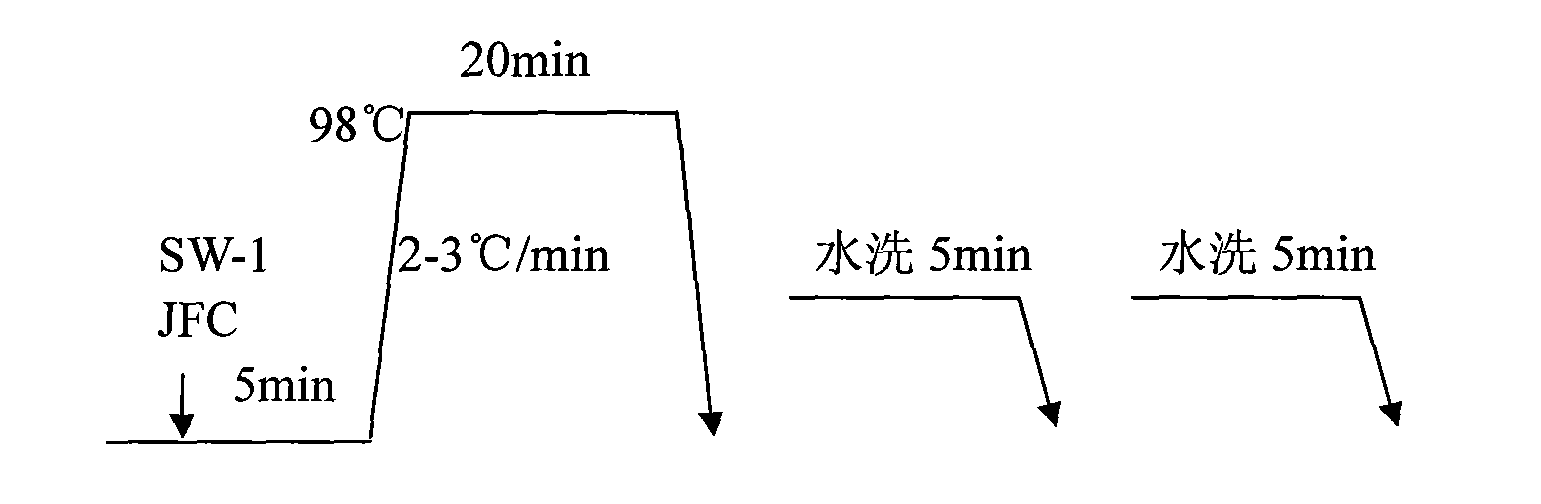

The invention discloses a production technology for an antibiosis moisture exhausting sock. The production technology includes the steps of firstly, preparing materials, wherein fiber used for knitting a fiber layer of the sock body is prepared through a yarn covering or yarn doubling method, knitted base yarn is manufactured, and components of the materials of the base yarn include 20% to 65% of natural bamboo fiber; secondly, dyeing the yarn through a sock dyeing machine; thirdly, conducting softening, wherein softening is conducted on the base yarn through softeners; fourthly, conducting knitting, wherein the base yarn is knitted into the sock body through a knitting machine, the base yarn of the natural bamboo fiber is knitted to form the sock body, and the sock body is sewn; fifthly, conducting disinfection, wherein antibiosis process treatment is conducted on the sock body through a sanitizer WS-8810 and an anti-bacterium agent; sixthly, conducting post processing, wherein the processed sock body is shaped to obtain a finished sock body. The sock has the antibiosis function and the sweat discharging function at the same time, is good in breathability, comfortable and soft and can still keep the extremely-strong antibiosis performance after being repeatedly washed.

Owner:浙江久渔针纺织有限公司

Coolmax fiber yarn dyed fabric and manufacturing method thereof

InactiveCN102080293AImprove warp evennessGood economic benefitsSynthetic fibresBiochemical fibre treatmentYarnEngineering

The invention provides a Coolmax fiber yarn dyed fabric and a processing technique thereof. In the invention, a Coolmax / cotton blended yarn is adopted, a fine-spun or poplin or oxford-spun or jacquard weave fabric is taken as a fabric texture, and the processing technique of the Coolmax fiber yarn dyed fabric adopts a special treatment method in yarn dyeing weaving. The Coolmax fiber yarn dyed fabric has the beneficial effects that the section of the adopted Coolmax fiber is in a unique four-pipe shape and is hollow, and the tube wall of the fiber is air permeable so that the fabric has excellent characteristics such as hygroscopicity, sweat exhaust, air permeability and the like due to the unique physical structure of the fiber, thus sweat on skins can be exhausted at any time and then transmitted to the fabric surface for rapid evaporation so that skins keep dry and comfortable. By means of breakthrough of the product in research and development as well as process, reference is provided for the development of top-grade personalized textile fabrics, guidance is provided for market development, and good economic benefit is created for enterprises.

Owner:TIANJIN TEXTILE ENG RES INST

Bamboo fiber knitting fabric

The present invention relates to one kind of bamboo fiber knitting fabric with blended bamboo fiber yarn as facing layer and spandex or chinlon yarn covered with the bamboo fiber. It features that the blended bamboo fiber yarn consists of bamboo fiber in 50-70 wt% and cotton, Modal, Tencel, wool, cashmere or Dacron in 30-50 wt%, and has count of 20-60 s and twist multiplier of 330-345. The bamboo fiber knitting fabric has the excellent performance of bamboo, including moisture absorption, permeation, health care and antibiotic property, etc. as well as improved costume performance and size stability, and is one kind of high grade comfortable material for underwear.

Owner:北京铜牛集团有限公司

Ultrathin leisure fabric with windproof and breathable functions and manufacturing method thereof

InactiveCN103932436AReduce weightWith windshieldSynthetic resin layered productsLaminationMicrometerCorrosion

The invention relates to an ultrathin leisure fabric with windproof and breathable functions and a manufacturing method of the ultrathin leisure fabric with the windproof and breathable functions. The method includes the steps that material is mixed; a blank is manufactured; pushing and pressing are performed; calendaring is performed; ungreasing treatment is performed; longitudinal stretching is performed; bi-directional stretching is performed in an arc shape; after transverse stretching, agglomeration and solidification are performed; films are attached through a release paper transferring method; the ultrathin leisure fabric is formed through glue compositing on textile fabric. The ultrathin leisure fabric manufactured through the steps is used for the fields of down garments, leisure sportswear, shoemaking and others, the thickness of the teflon microporous film is 2 micrometers-5 micrometers, the pore diameter is 0.5 micrometer-2 micrometers, and the porosity is over 80%. The ultrathin leisure fabric has the multiple functions of being light in weight, windproof, waterproof, breathable and resistant to ultraviolet and corrosion, discharging sweat and keeping warm and is suitable for various products, which are made of functional materials, for kinds of sports, leisure and women and children.

Owner:HUZHOU SENNUO FLUORINE MATERIAL TECH

Method for manufacturing pineapple leaf fiber anti-acarid mat

InactiveCN101564255AImprove performanceGood moisture absorption and breathabilityYarnBed-coversYarnTextile fiber

The invention discloses a method for manufacturing a pineapple leaf fiber anti-acarid mat. The method comprises the steps of: firstly opening and mixing raw fiber materials; secondly spinning the raw fiber materials into single yarns and weaving the single yarns into raw fabric; and finally trimming the raw fabric. The method is characterized by adopting the raw fiber material consisting of 30 to 50 mass percent of pineapple leaf fiber and 5 to 70 mass percent of other textile fibers which can be one, two or three types of fibers of hemp fiber, flax fiber or cotton fiber. The pineapple leaf fiber anti-acarid mat has the functions of cooling, moisture absorbing, moisture releasing, ventilating, feeling soft and comfortable, eliminating urtication and the like, and also has the excellent effect of resisting and preventing acaid; and the anti-acarid rate can reach more than 80 percent. The trimming process adopted by the invention can remove both oil stain in spinning process and a little of colloid and filoplume contained in hemp fiber so as to lead the mat to be softer, even, washing-durable, shrink-resistant, storage-durable and use-durable.

Owner:AGRI MACHINERY INST CHINESE TROPICAL ACAD OF SCI

Preparation method for antibacterial polyester fibre with moisture absorption and perspiration elimination, and prepared fiber thereof

PendingCN111893598ASimple processEasy to operateSpinnerette packsMelt spinning methodsPolyesterFiber

The invention discloses a preparation method for an antibacterial polyester fibre with moisture absorption and perspiration elimination, and a prepared fiber thereof. The method comprises the steps ofselecting raw materials; grinding the raw materials to obtain polyester powder; mixing the polyester powder with plastic agents and forming agents, and adding mixtures to an internal mixer; obtainingmixtures A; mixing graphene oxide powder with modifiers, and heating and stirring the graphene oxide powder and the modifiers to obtain mixtures B; adding the mixtures A and the mixtures B to a granulator, and adding reinforcing agents and micropore agents; obtaining polyester master batch through melt extrusion; mixing the master batch with polyester slices, and adding mixtures to a spinning machine; making polyester into silk; drawing fibers into a shape with grooves; forming micropores at the interior and exterior of the fibers through a solvent dissolution slot; winding and coiling the formed silk, and airing the silk; and storing the silk for standby application after oiling. The invention further provides the fiber prepared with the method. According to the preparation method, graphene and other additives are added in the preparation process of the master batch, and the antibacterial property is improved; meanwhile, the fiber appearance is improved through a special spinneret hole process, and the functions of moisture absorption and perspiration elimination are improved.

Owner:NANTONG QIANGSHENG SAFETY PROTECTION TECHNOLOGY CO LTD

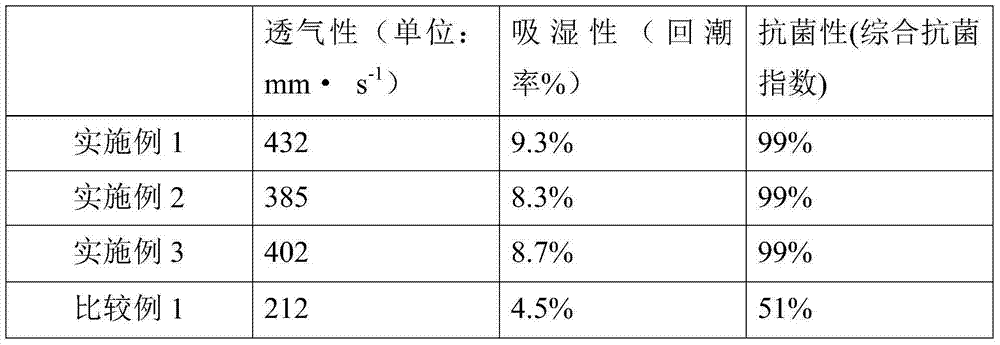

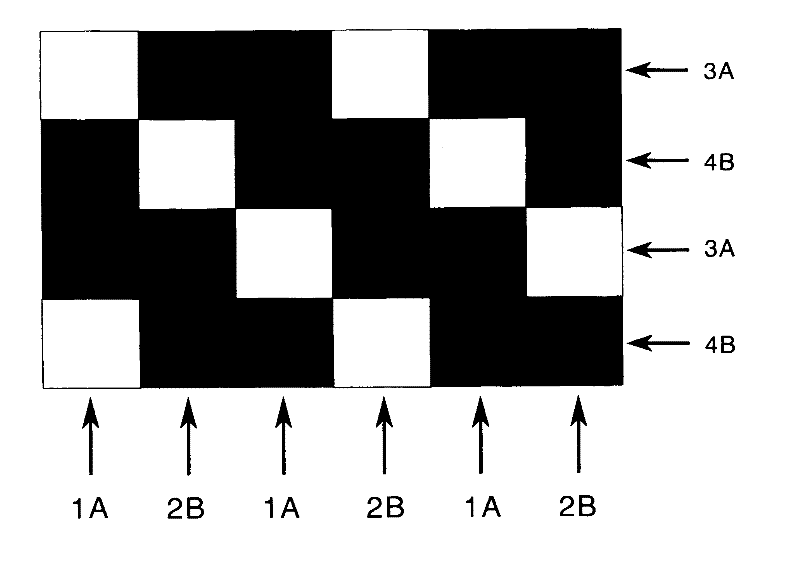

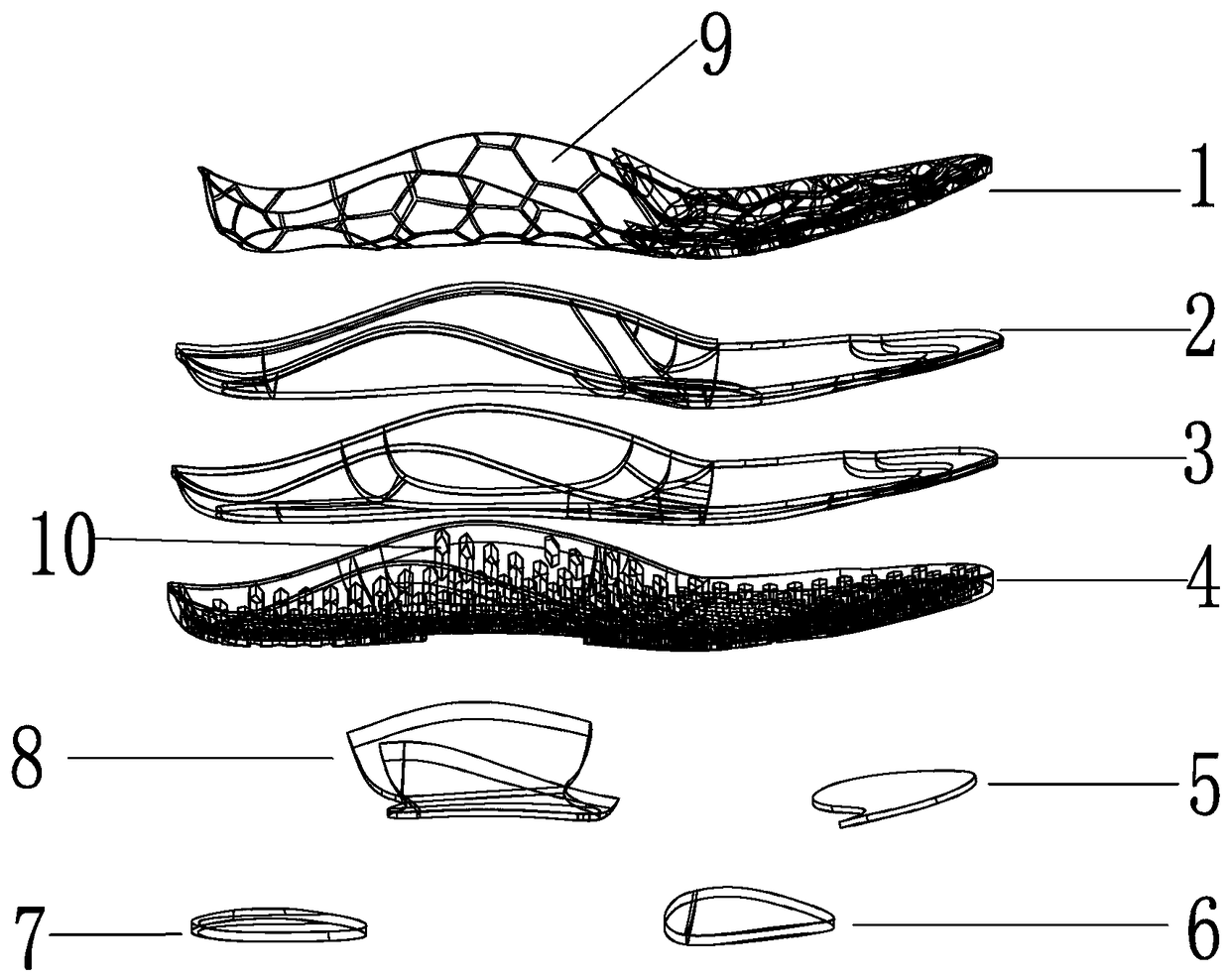

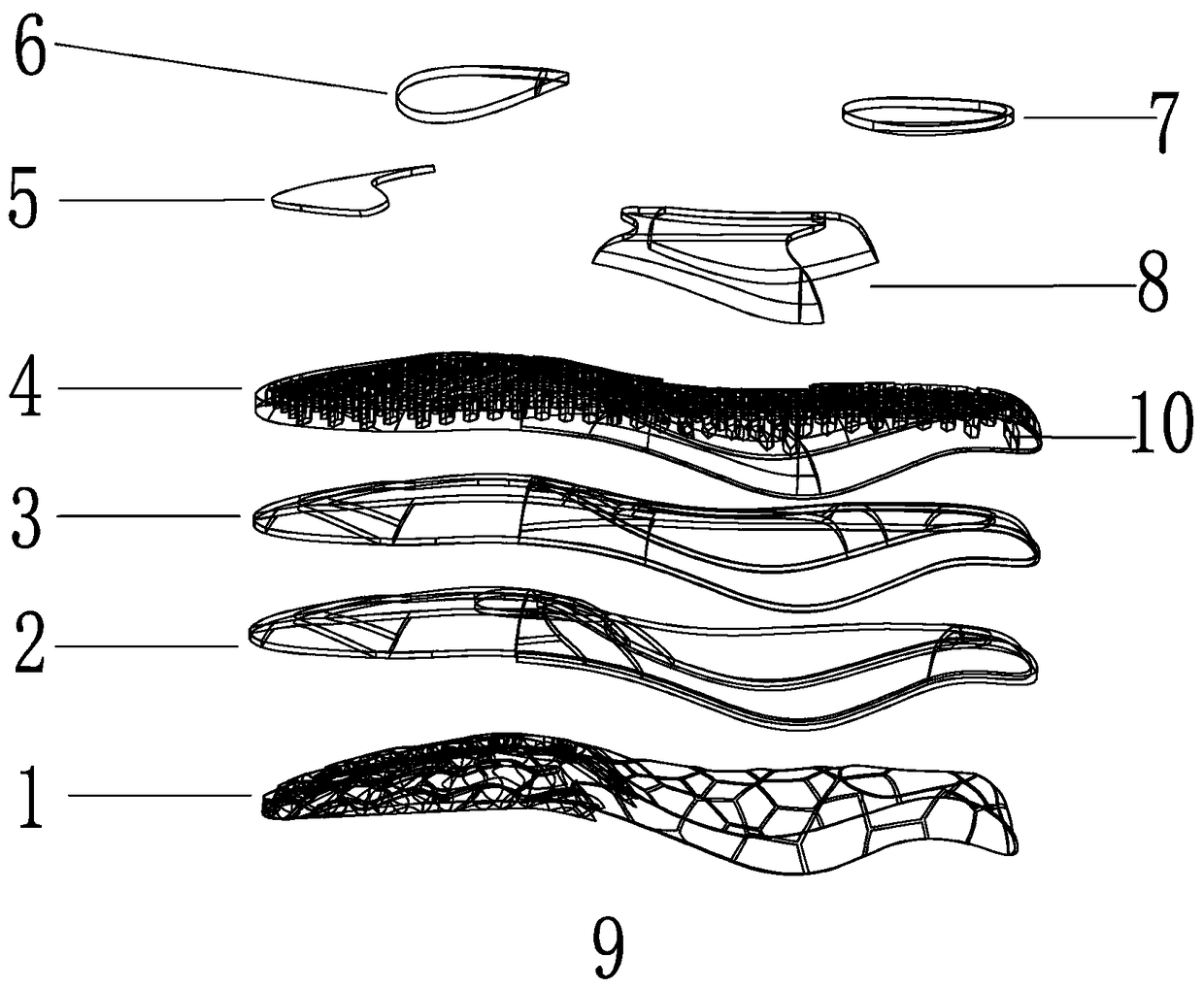

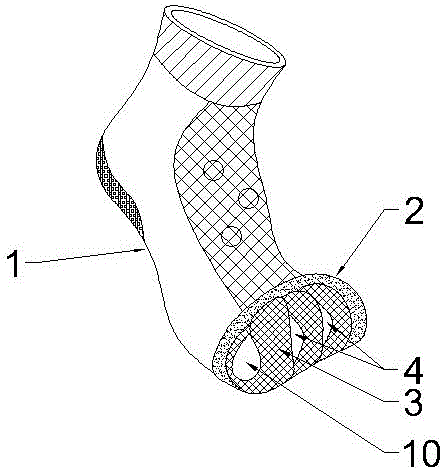

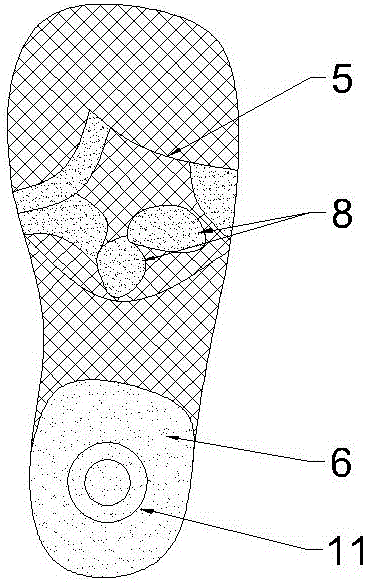

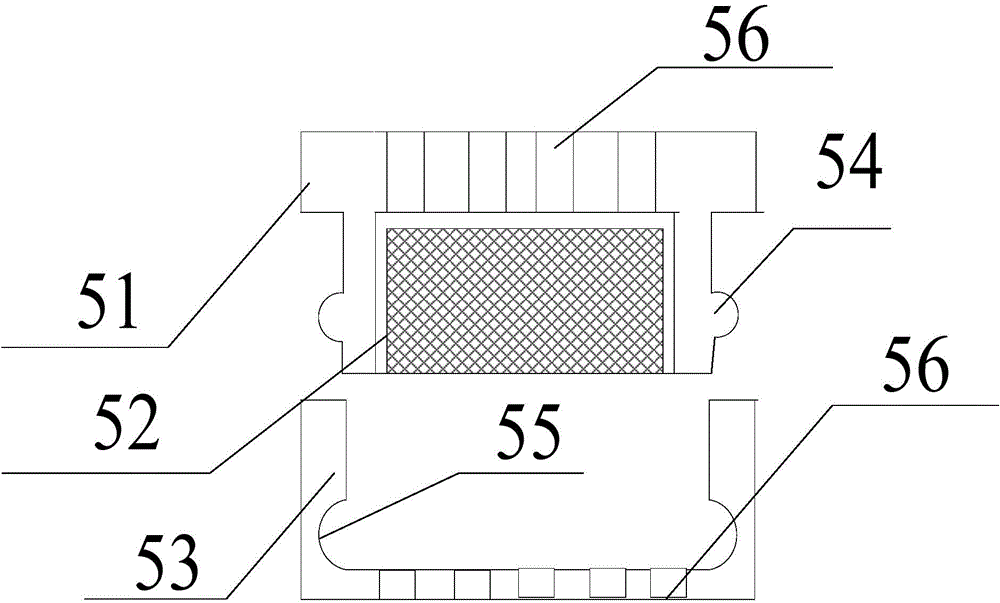

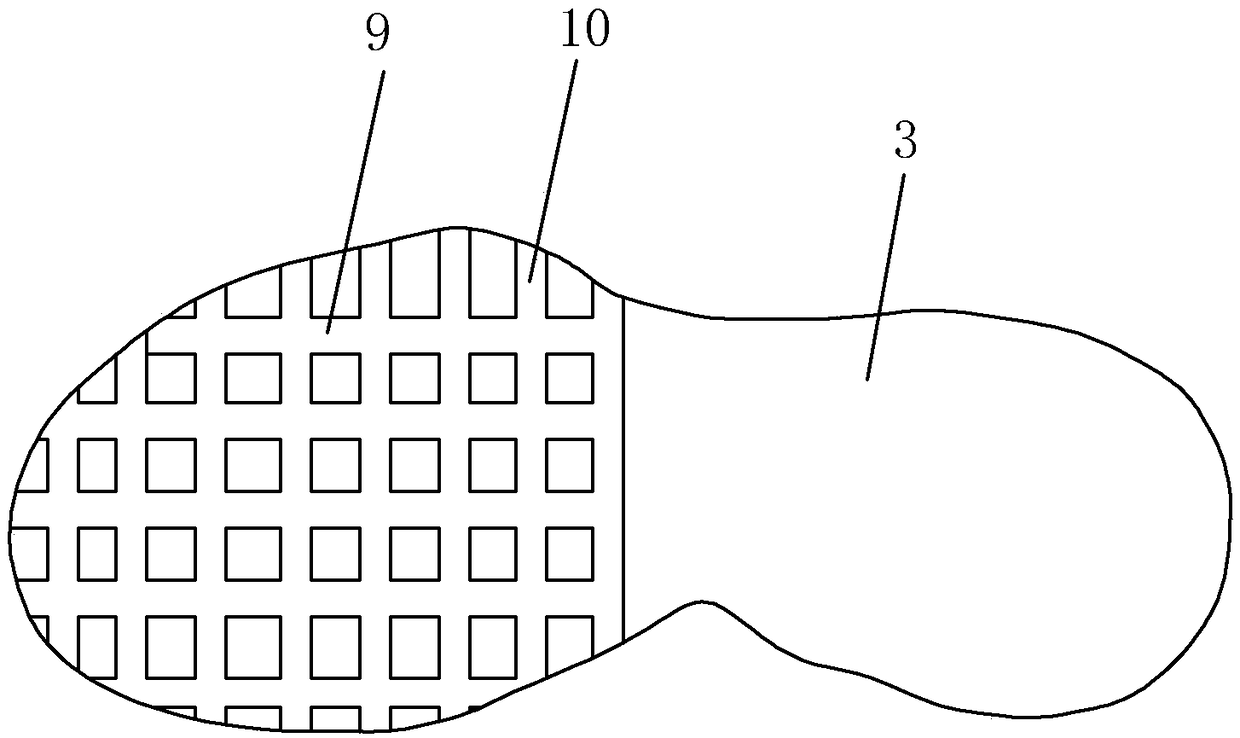

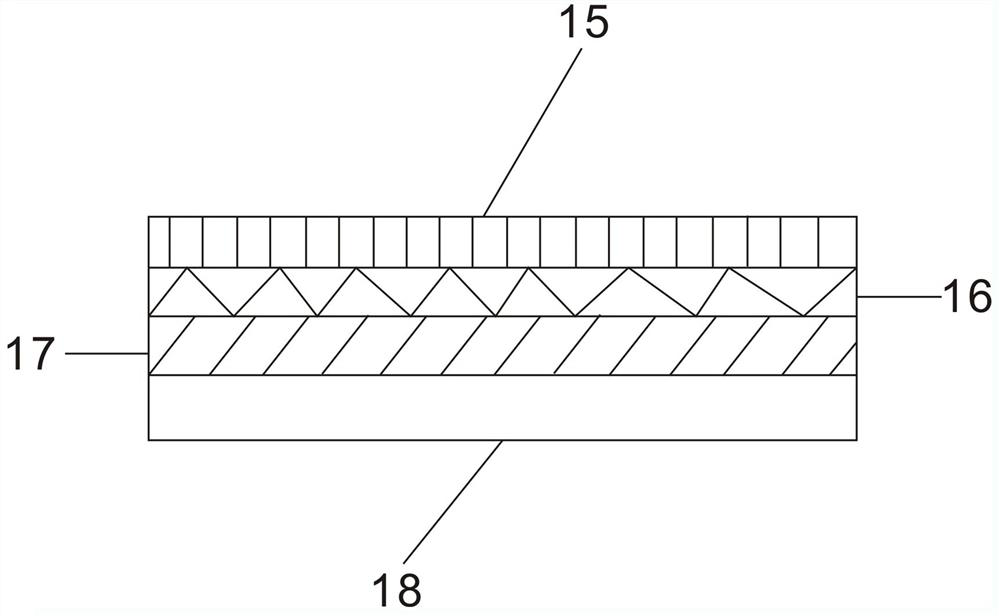

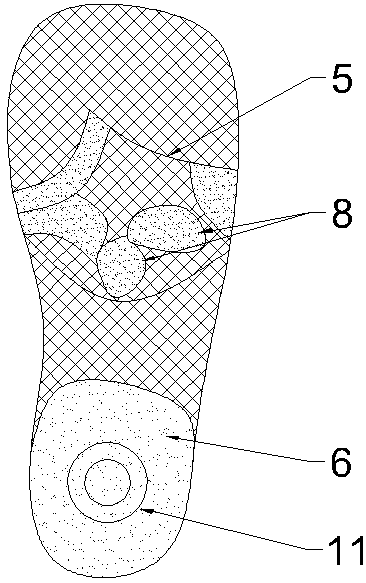

Environment-friendly thickened stitch-bonded nonwoven fabric, production technology and insole

The invention discloses an environment-friendly thickened stitch-bonded nonwoven fabric which can be used for making of products such as bags, insoles and floor mats. The environment-friendly thickened stitch-bonded nonwoven fabric is made of environment-friendly raw materials, the thickness of the fabric is larger than that of ordinary stitch-bonded nonwoven fabric, and the air permeability and hygroscopicity are good. The invention relates to an insole made of the environment-friendly thickened stitch-bonded nonwoven fabric, when a person wears the insole, the insole cannot collapse by being subjected to pressure of the foot for a long time, patterns on the surface have the massage effect, the set time is long, deformation is not prone to occur, and the insole has the effects of being air permeable, resistant to odor and capable of absorbing sweat, draining sweat and removing moisture. The insole is put into a shoe, foot pain caused by a long walk can be relieved, and the body health is significantly improved.

Owner:特斯(中国)有限公司

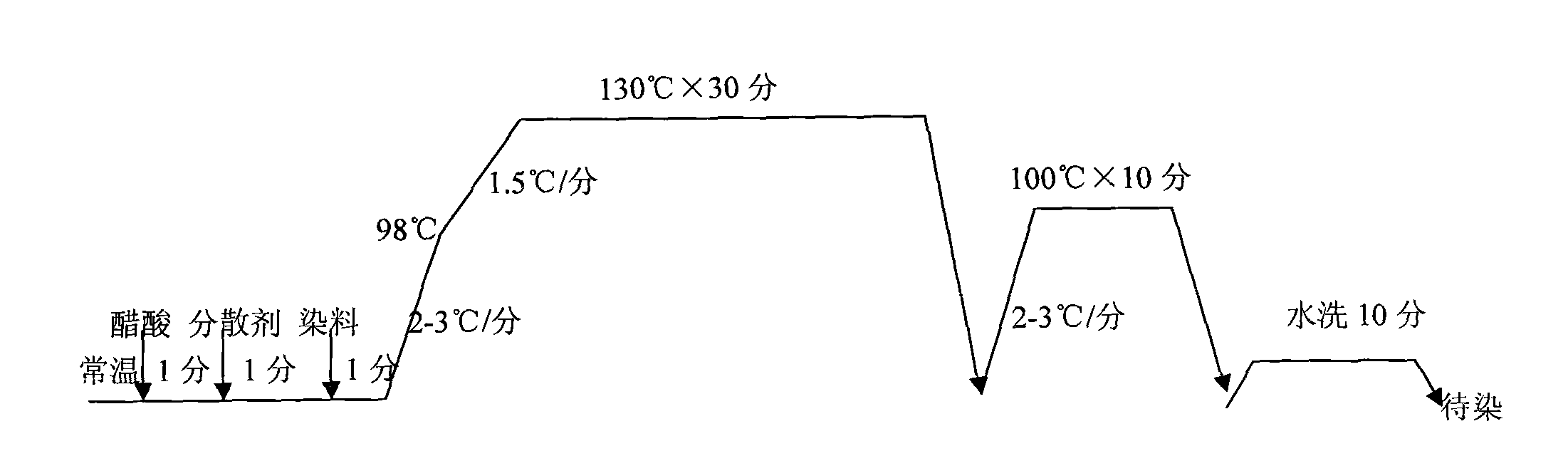

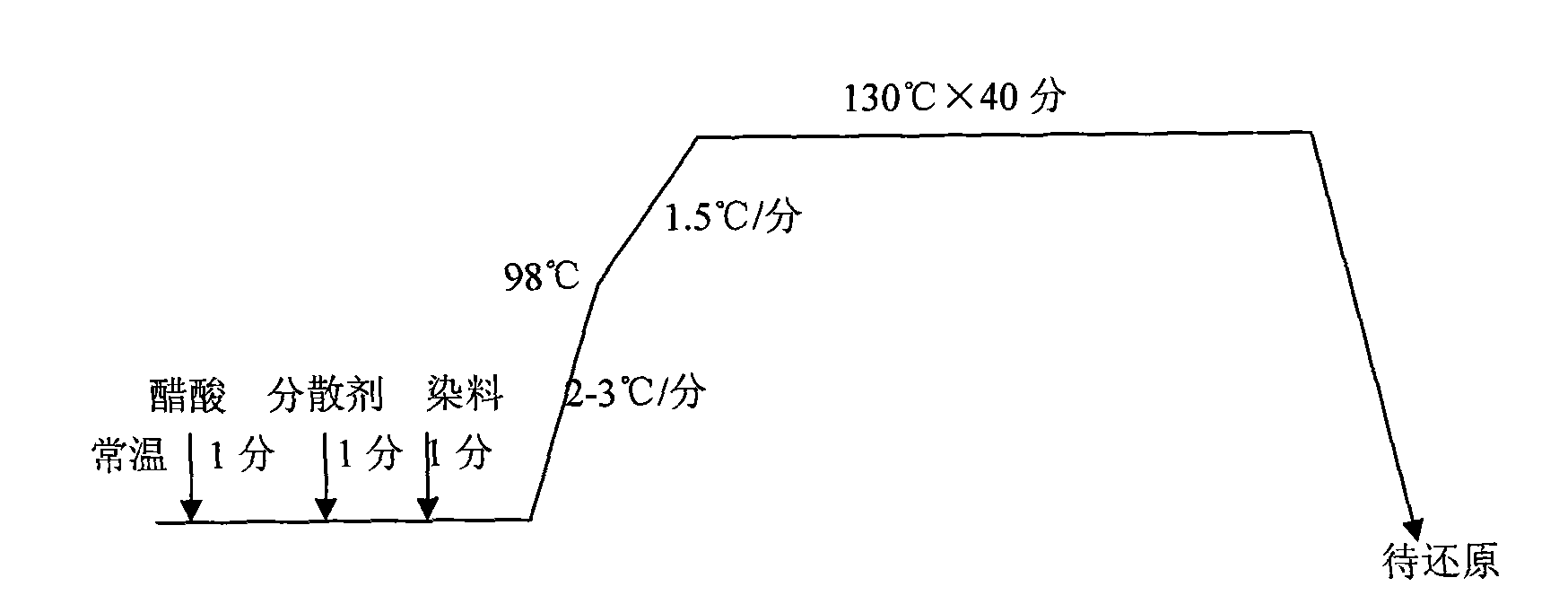

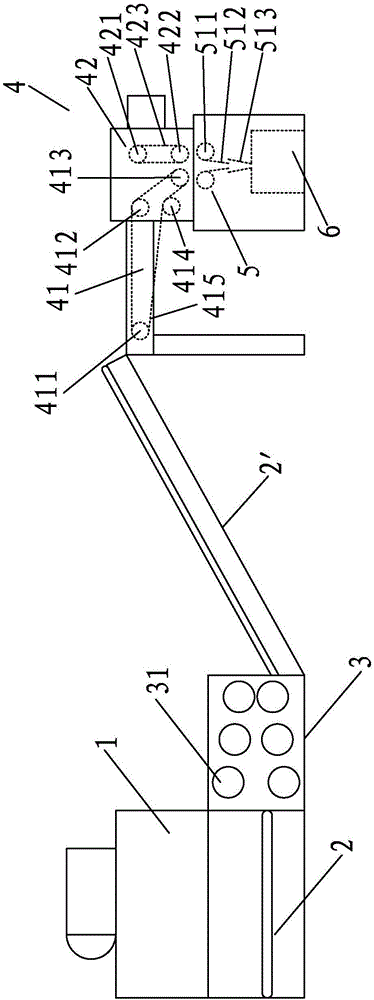

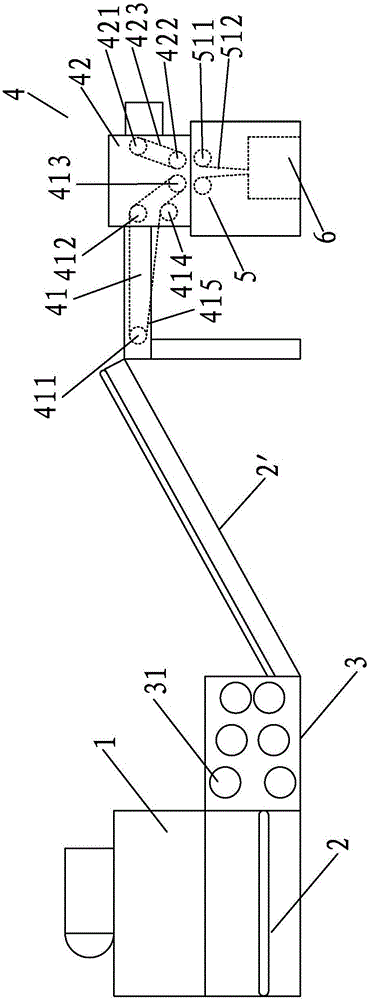

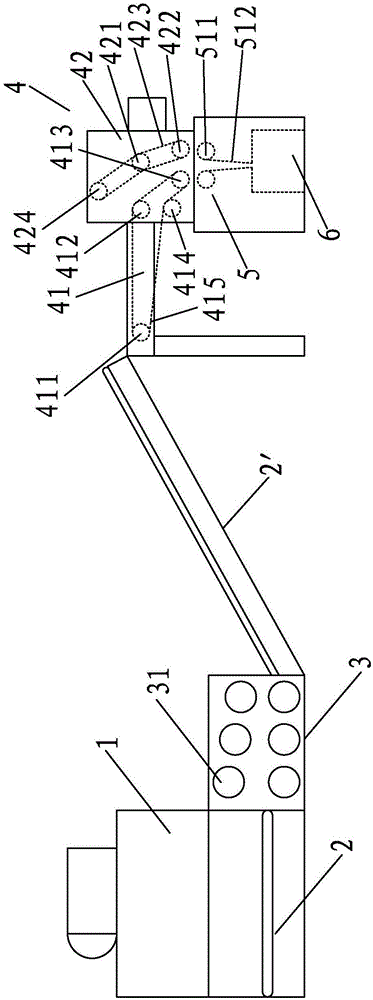

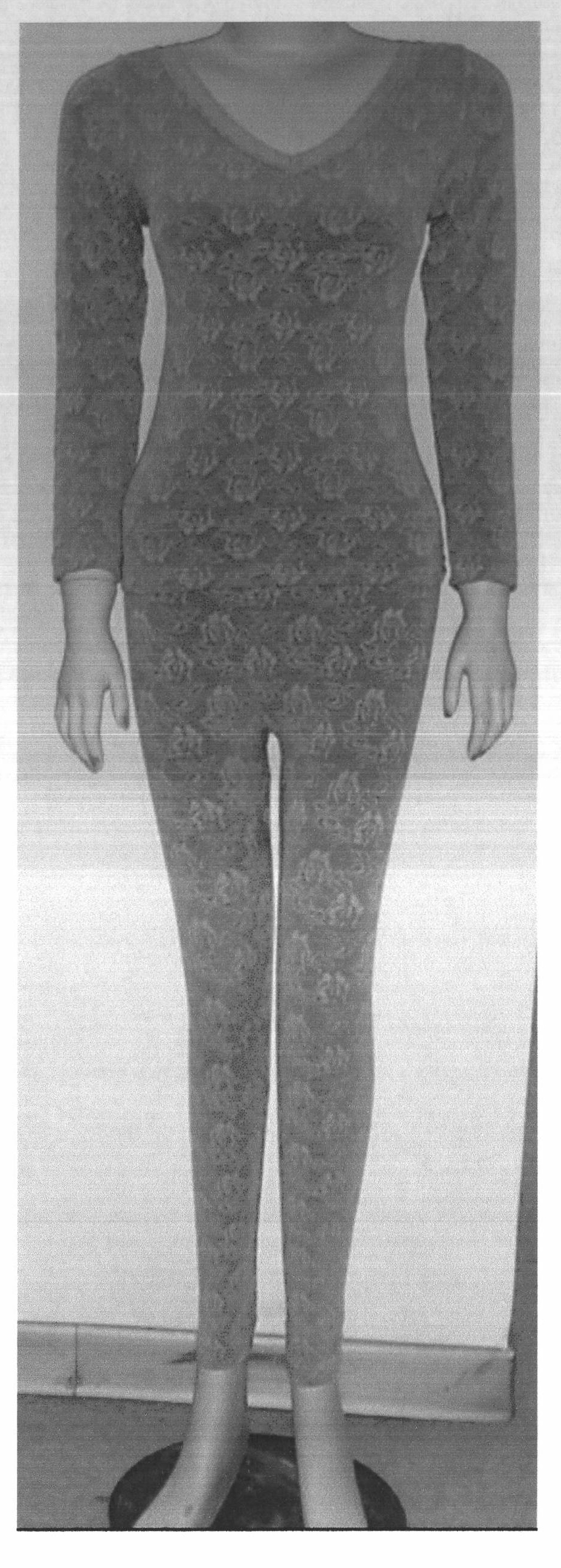

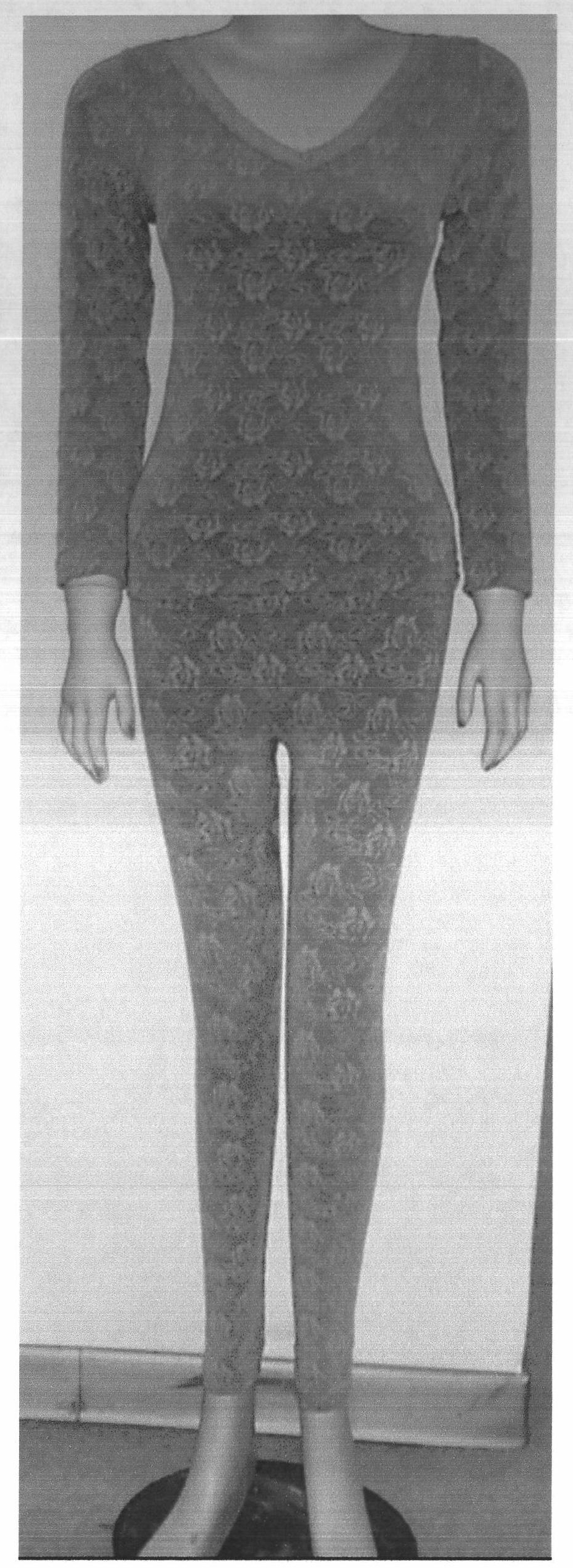

Technology for producing Shukanglun silk seamless underwear

The invention discloses technology for producing Shukanglun silk seamless underwear and belongs to the technical field of production of functional garments. The technical process is divided into two parts, namely circular knitting machine weaving technical process and seamless underwear weaving technical process. By adopting the production technology, the Shukanglun silk seamless underwear produced from the combination of three raw materials of super-fine-denier dyeable polypropylene novel fiber raw materials, natural mulberry silk and bamboo fiber is developed, and whole-process technical tracking is performed through the aspects of fabric raw materials, texture structure, type design, shell fabric weaving, printing and dyeing technical scheme and the like. The Shukanglun silk seamless underwear developed by the combination of the natural mulberry silk, the super-fine-denier dyeable polypropylene and high-count bamboo fiber is luxuriant, soft, stiff and smooth, beautiful and close-fitting, comfortable to wear, high in moisture absorption, moisture conductivity and air permeability, has soft texture, no toxin, pilling resistance, bacteria resistance and inhibition and the function of skin care, and solves the problems that mulberry silk fabrics produced by the conventional production technology fit to a body easily when the body sweats and are uncomfortable to wear and the like. The Shukanglun silk seamless underwear produced by the production technology is particularly comfortable to wear, beautiful and unique.

Owner:SHAOXING HENGMEI FANCY SILK

Ultrathin polytetrafluoroethylene membrane fabric and embossing technology thereof

ActiveCN104325767AReduce weightWith windshieldLamination ancillary operationsSynthetic resin layered productsPorosityUltraviolet

The invention relates to ultrathin polytetrafluoroethylene membrane fabric and an embossing technology thereof. The embossing technology comprises the steps of mixing materials; preparing blanks; pushing; calendaring; degreasing; carrying out longitudinal stretching; carrying out arc-shaped bi-directional stretching; carrying out transverse stretching; sintering for curing; applying the membrane by a release paper transferring method; gluing to shape the textile fabric; and carrying out the embossing technology. With the above steps, the prepared ultrathin embossed fabric can be applied in various fields such as f recreational sportwear and shoemaking. The thickness of the polytetrafluoroethylene microporous membrane is 2-5 [mu]m; the aperture is 0.5-2 [mu]m; and the porosity is higher than 80%. The ultrathin polytetrafluoroethylene membrane fabric has a plurality of functions of having beautiful appearance and light weight, shielding wind, expelling sweat, being waterproof and moisture permeable, preventing ultraviolet rays, preventing corrosion and keeping warm, and is suitable for a variety of products such as be used as functional materials for various sports, relaxation and women and children.

Owner:HUZHOU SENNUO FLUORINE MATERIAL TECH

Pure polylactic acid fiber underwear shell fabric and manufacturing method thereof

InactiveCN104287104AHas natural antibacterialNon-allergenicWeft knittingArtificial thread manufacturing machinesFiberPlant Sources

The invention relates to pure polylactic acid fiber underwear shell fabric, and belongs to the technical field of textile. The problem that in the prior art, 100% pure spinning of polylactic acid fibers can not be achieved is solved. The pure polylactic acid fiber underwear shell fabric is formed by spinning 100% pure polylactic acid fibers, and the shell fabric is formed by weaving 50-150 D polylactic acid fibers DTY filaments and 30-75 D polylactic acid fibers FDY filaments. The pure polylactic acid fiber underwear shell fabric has the following advantages that the shell fabric is made of the 100% pure polylactic acid fibers and has the advantages of pure natural bacteriostasis and the non-sensitization effect, the plant source fibers have the life cultivation and health preservation functions such as smoothness, breathability, sweat drainage, itching relieving, bacteria resistance, bacteriostasis and skin-friendly and skin care performance, and the shell fabric has excellent stretch stability.

Owner:JIAXING NEW FASHION ECOLOGICAL TEXTILE SCI & TECH CO LTD

Tencel and T400 jean stretch fabric

Owner:SHAOXING SHULILE TEXTILE PROD

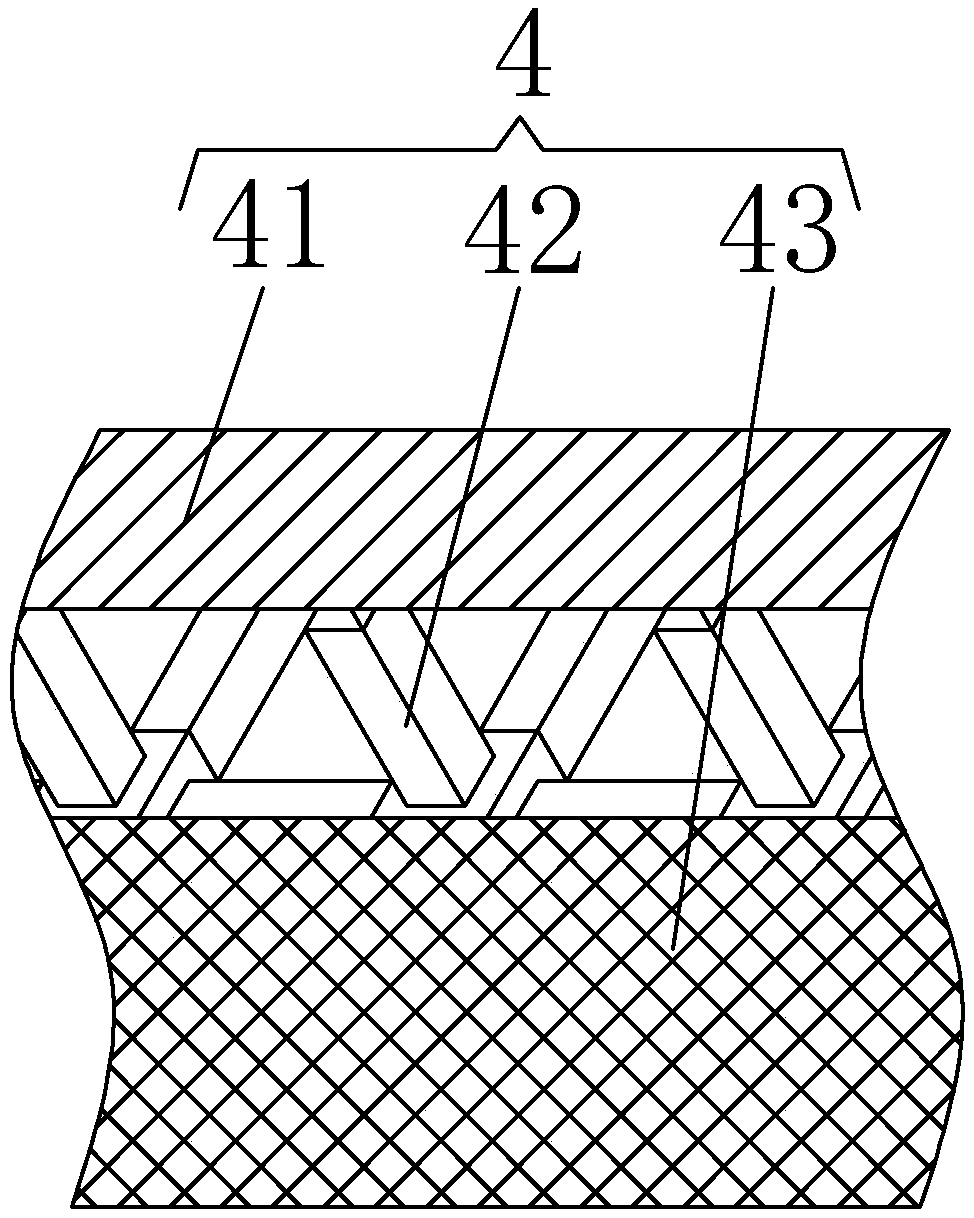

Football insole

ActiveCN108634482AMildew proofWith perspirationInsolesArtificial filaments from viscoseHuman bodyPerspiration

The invention discloses a football insole, and relates to the technical field of insoles. The football insole comprises an insole body, the insole body comprises a nanometer bamboo charcoal fiber layer, a first polyurethane layer, a second polyurethane layer and a third polyurethane layer from top to bottom in sequence, shock-absorption pads are arranged at the position, corresponding to toes of ahuman body, of the lower side of the front end of the third polyurethane layer, the position, corresponding to the front sole of the human body, of the lower side of the front end of the third polyurethane layer, and the position, corresponding to the heel of the human body, of the lower side of the rear end of the third polyurethane layer respectively, and an elastic foot-protecting portion is arranged at the position, corresponding to the foot arch of the human body, of the lower side of the third polyurethane layer; multiple hexagonal protrusions are evenly distributed on the upper side ofthe nanometer bamboo charcoal fiber layer, and multiple penetrating holes in the vertical direction are arrayed in the third polyurethane layer. A wearer can wear the football insole comfortably, thefootball insole can deform and make shock absorption by catering to the protruding portion of a foot, and therefore the effect of foot protection is high. The toes, the front sole, the foot arch andthe foot heel of the wearer can be effectively protected, air permeability is good, and the functions of resistance to mildew, bacteria and odor, perspiration and the like are realized.

Owner:DONGGUAN SHUNFENG SPORTS EQUIP CO LTD

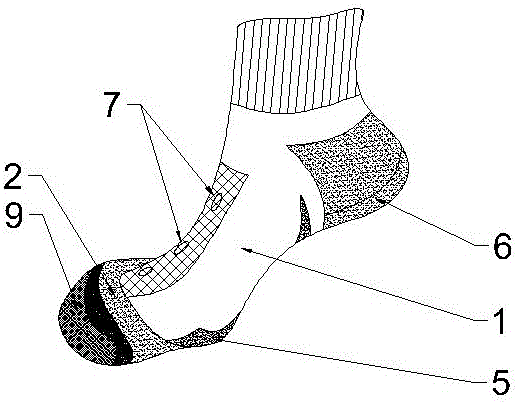

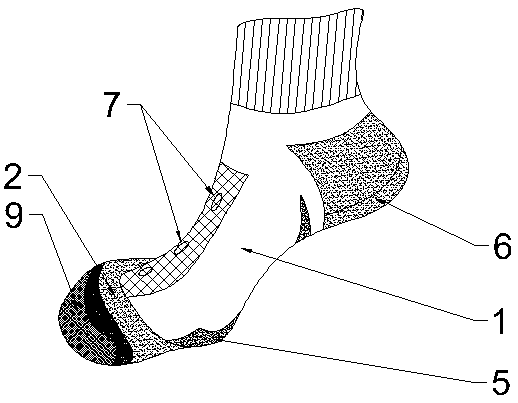

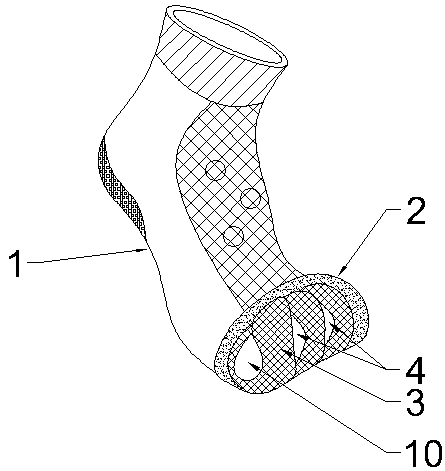

Multi-functional massage sock

ActiveCN106690441AAvoid squeezingAvoid scratchesElectrotherapyDevices for pressing relfex pointsPerspirationMassage

The invention provides a multi-functional massage stock which comprises a sock body. A thickening mat toe ring is arranged on the head of the sock body; a plurality of toe care blocks are placed on the front side of the mat toe ring, a former thickening layer is placed at the bottom of the front foot of the sock body, and a back thickening layer is placed at the back foot of the sock body. The sole part between the former thickening layer and the back thickening layer is network-like, and the instep part of the sock body is network-like. The network-like structure of the instep part is provided with a plurality of circular massage bosses, and toe covers are placed outside the toe care blocks. A user feels more skin-friendly and comfortable when wearing the sock, and a series of problems such as foot massage, health care, ventilation, perspiration, smelly feet and the like are solved.

Owner:辽源隆鑫源纺织贸易有限公司

Silver fiber interwoven radiation-proof shirt fabric

InactiveCN102312327AAntibacterialDeodorizingShieldingWoven fabricsMoisture absorptionElectromagnetic radiation

The invention discloses a silver fiber interwoven radiation-proof shirt fabric, which comprises warps and wefts, wherein nano silver fibers, two-strand combed cotton color yarns and maifan stone color yarns are respectively selected and used as the warps; nano silver fibers and Tencel color yarns are respectively selected and used as the wefts; and the warps and the wefts adopt a one-up one-down plain weave. Compared with common shirt fabrics, the shirt fabric disclosed by the invention has obvious advantages, i.e. the shirt fabric can effectively prevent electromagnetic radiation, has the efficacies and characteristics of bacteria resistance, deodorization, moisture absorption, good air permeability, body temperature regulation, skin pH value regulation, good antistatic property, water washing resistance, high wearing comfortableness and the like, and is an environment-friendly hygienical functional fabric which is preferred by the clothing industry for producing radiation-proof shirts.

Owner:SHAOXING SHULILE TEXTILE PROD

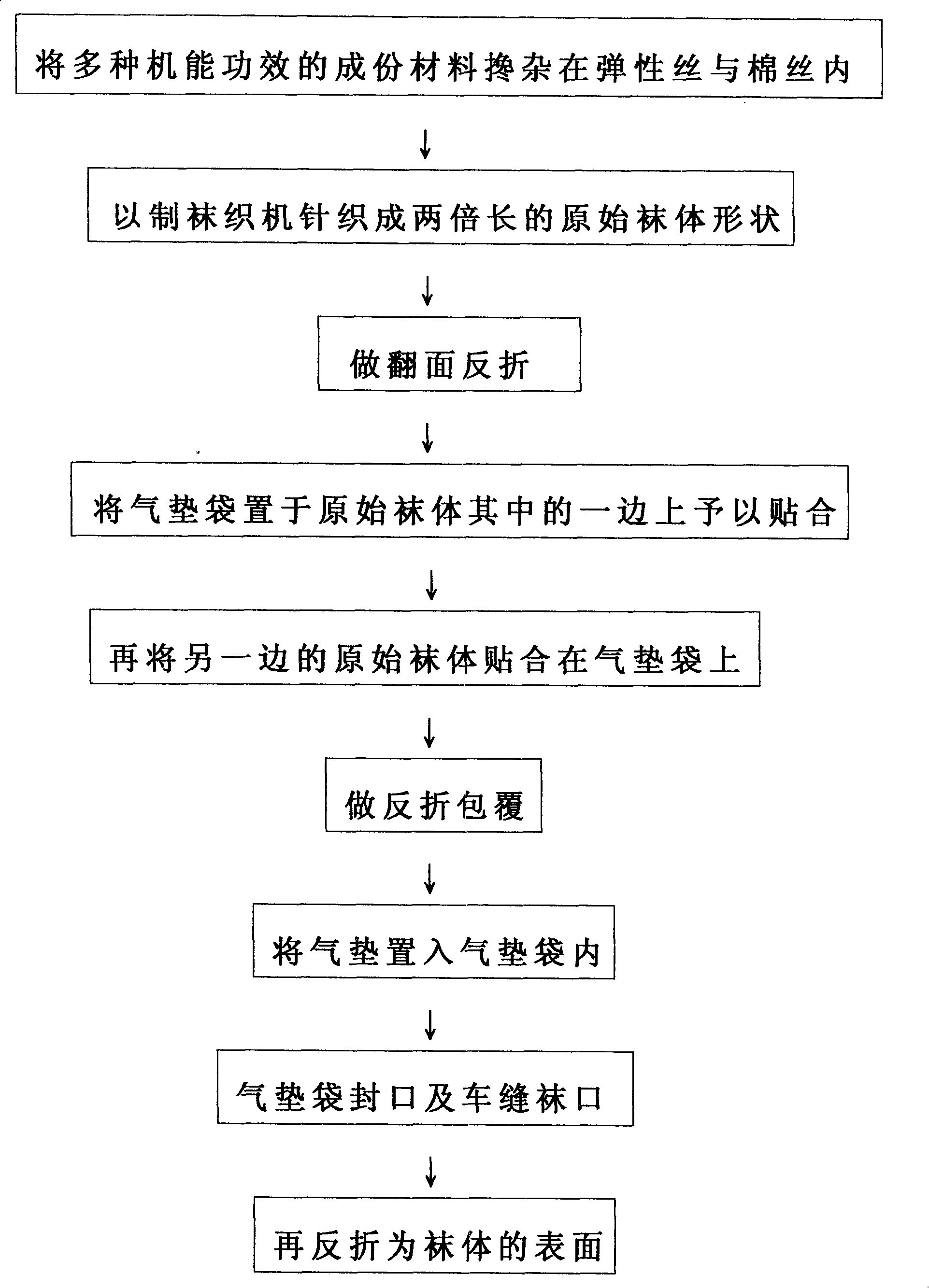

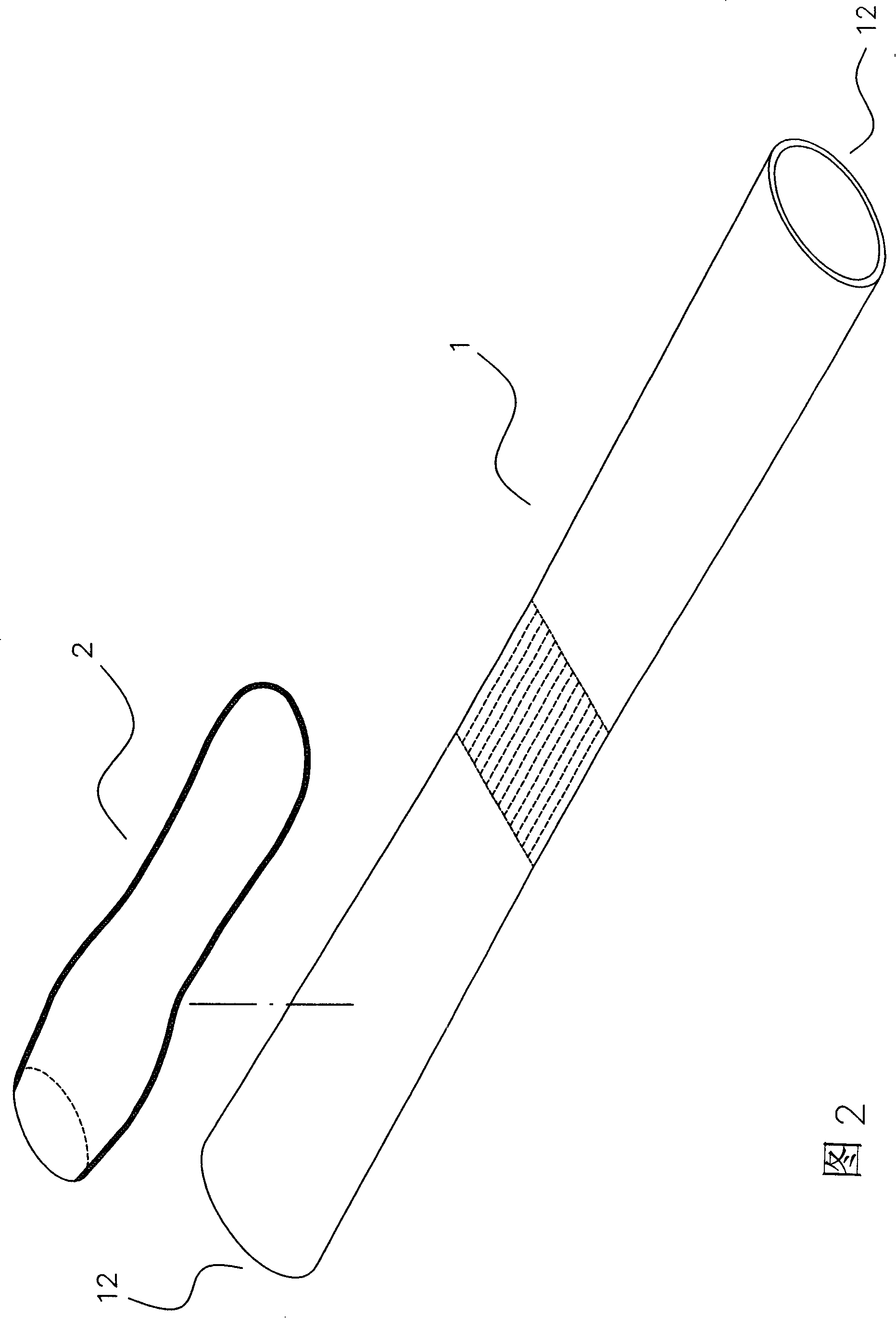

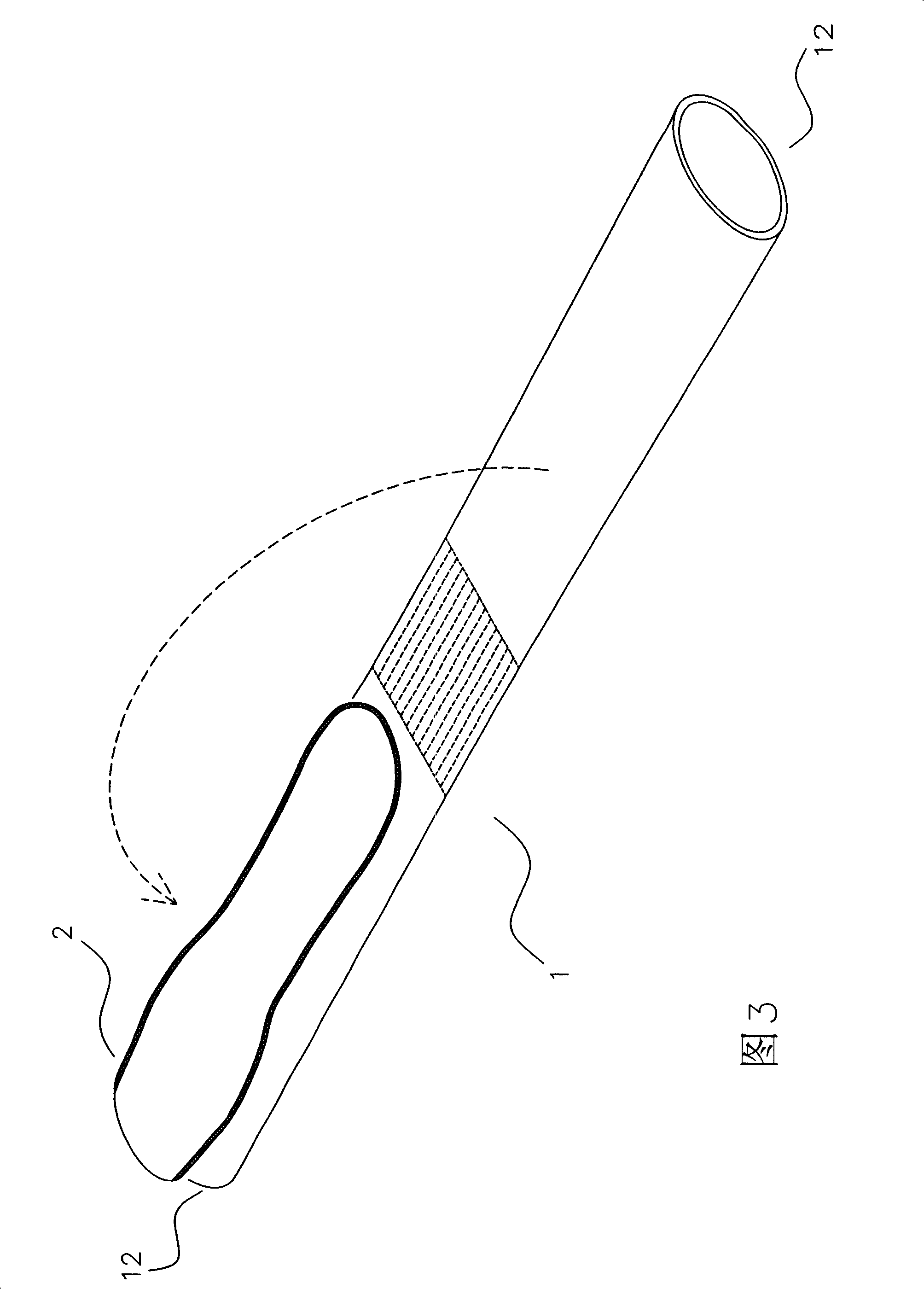

Elastic air cushion socks and its preparing method

InactiveCN101199366AReduce consumptionWith shock absorbersPanty-hoseHosieryEnergy consumptionCushion

Disclosed is a method to make elastic pneumatic socks, including the following steps: mingle component material with multiple functions in elastic silk or cotton threads to form the material for the socks, knit the material with a loom into a sock which is two times the length of the original sock, turn over the sock and then fold the sock, arrange a preformed pneumatic cushion bag at one side of the sock, position the pneumatic cushion bag on both sides and then turn over the sock, put a pneumatic cushion in the pneumatic cushion bag and seal the bag, sew the opening of the double-layer sock, at last turn over the sock to turn the inside to be the surface of the sock. Therefore, the sock is comfortable and is light in weight and has the multiple functions of reducing human body energy consumption, ventilating and resisting bacteria.

Owner:捷盈实业股份有限公司

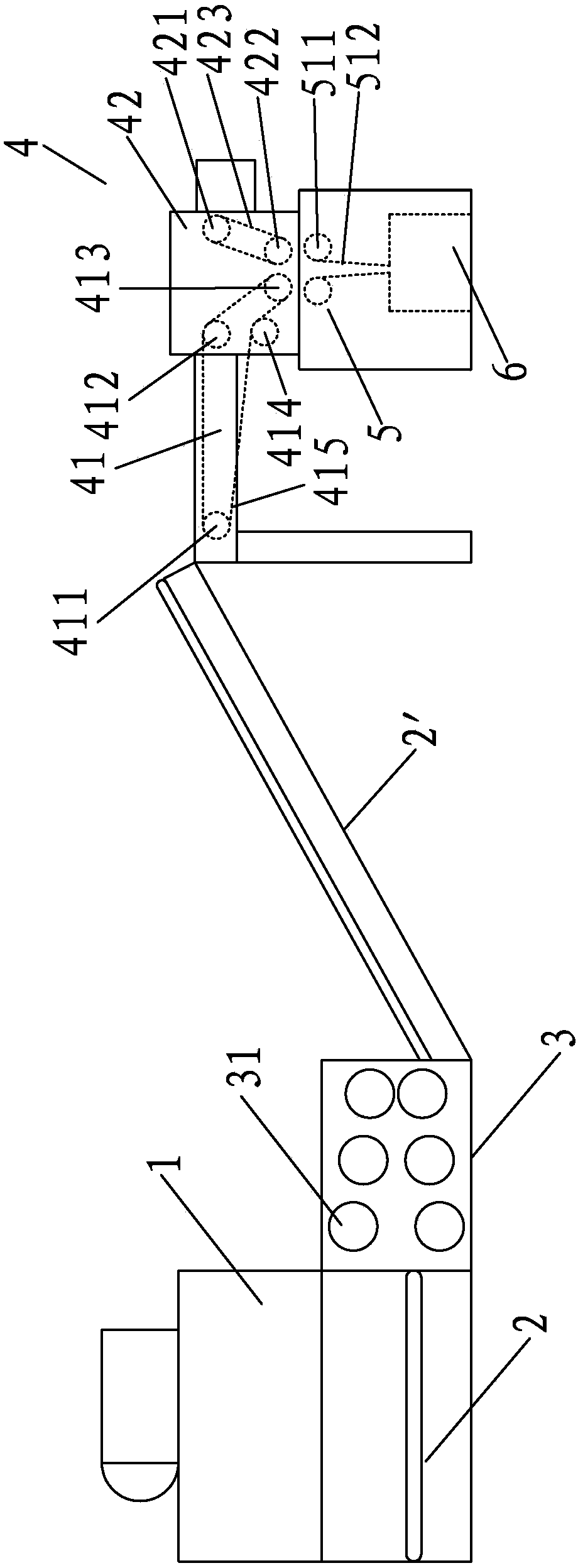

Production technology of continuously spun viscose fiber with special-shaped cross section

PendingCN110184665ABreathableHigh color fastnessArtificial filaments from viscoseWet spinning methodsWind systemPolyethylene glycol

The invention discloses a production technology of a continuously spun viscose fiber with a special-shaped cross section. The production technology comprises the specific processes that a viscose stock solution is sprayed into an acid bath through a spinning jet for a reaction to generate as-spun filaments, the concentration of sulfuric acid in the acid bath is 120-160 g / L, the concentration of sodium sulfate is 200-270 g / L, the concentration of an auxiliary agent polyethylene glycol polyamine BEROL SPIN 652 is 10-200 ppm, the temperature of the acid bath is 47-60 DEG C, the as-spun filamentsare formed in a glass tube, is subjected to stretch forming at a spinning speed of 80-170 m / min, and then is wound into a reel through a winding system, and finally, the continuously spun viscose fiber with a star-shaped cross section is obtained. The production technology of the continuously spun viscose fiber with the special-shaped cross section has the advantages that a new technology for continuously spinning zinc-free fibers through viscose is adopted, the technology is simple, the cost is low, the pollution to a water body caused by the discharge of zinc sulfate along with wastewater iseffectively avoided, the environmental protection effect is better, in addition, the prepared product has a larger specific surface area and also has functions of flatness and smoothness, moisture absorption, breathability, sweat discharge and the like, and the market prospect is wide.

Owner:XINXIANG CHEM FIBER

Manufacturing method of multi-component variable-structure functional sports socks

The invention discloses a manufacturing method of multi-component variable-structure functional sports socks. According to the multi-component variable-structure functional sports socks, short ultra-high molecular weight polyethylene fibers, Coolmax, hemp and other functional fibers and traditional raw materials are combined and used for weaving of different portions of the socks respectively, reasonable organization structure design is conducted on the different portions of the socks, and sock blanks are woven through a computer hosiery machine, and then shaped and arranged. The manufactured multi-component variable-structure functional sports socks containing the short ultra-high molecular weight polyethylene fibers, the Coolmax, the hemp and other functional fibers have the advantages of being capable of absorbing moisture, exhausting sweat and achieving deodorization, resistant to bacteria and abrasion, comfortable to wear and the like, and can completely meet the requirements of high-grade sports socks for integrating the functions of comfort, sanitation, healthcare, wear resistance and the like.

Owner:IANGSU COLLEGE OF ENG & TECH

Health-care herbal hair dye

InactiveCN105106078ABright colorPromote sleepCosmetic preparationsHair cosmeticsCassia grandisAdemetionine

The invention discloses health-care herbal hair dye, comprising, by weight, 1-4 parts of dyeing liquid, 0.5-3.5 parts of common Bletilla tuber, 5-9 parts of common Anemarrhena rhizome, 4-8 parts of mugwort, 5-10 parts of honeysuckle flower, 3-9 parts of lavender, 6-9 parts of garden balsam, 10-15 parts of cassia seed, 2.5-7.5 parts of saffron, 3-8 parts of dandelion herb and the balance of health-care material. Through the above composition, the health-care herbal hair dye features perspiration, cooling, bright color and moisturizing, natural aromatic essence is kept in the dye, using the dye often helps activate blood circulation to dissipate stasis, inhibit germs and diminish swelling, and meanwhile, the dye further helps promote human body sleep and care human health.

Owner:SUZHOU LOTTE CHEM TECH

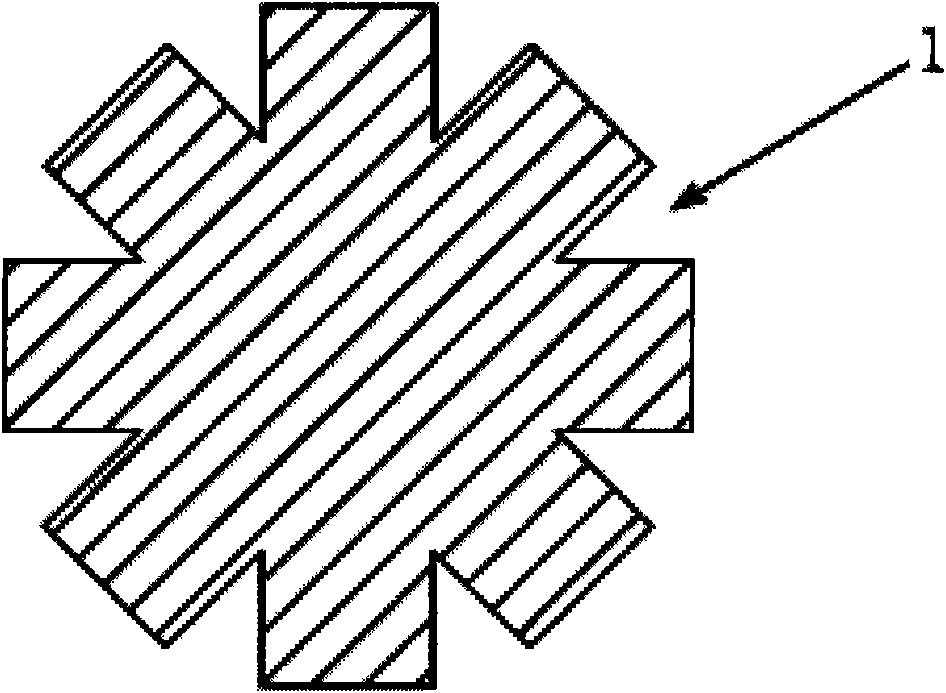

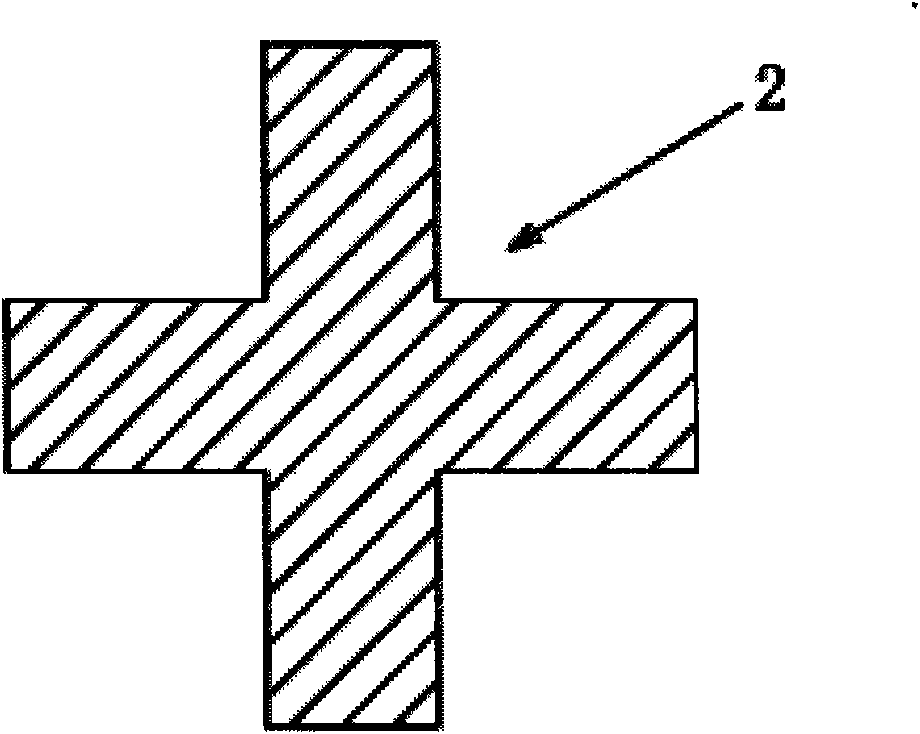

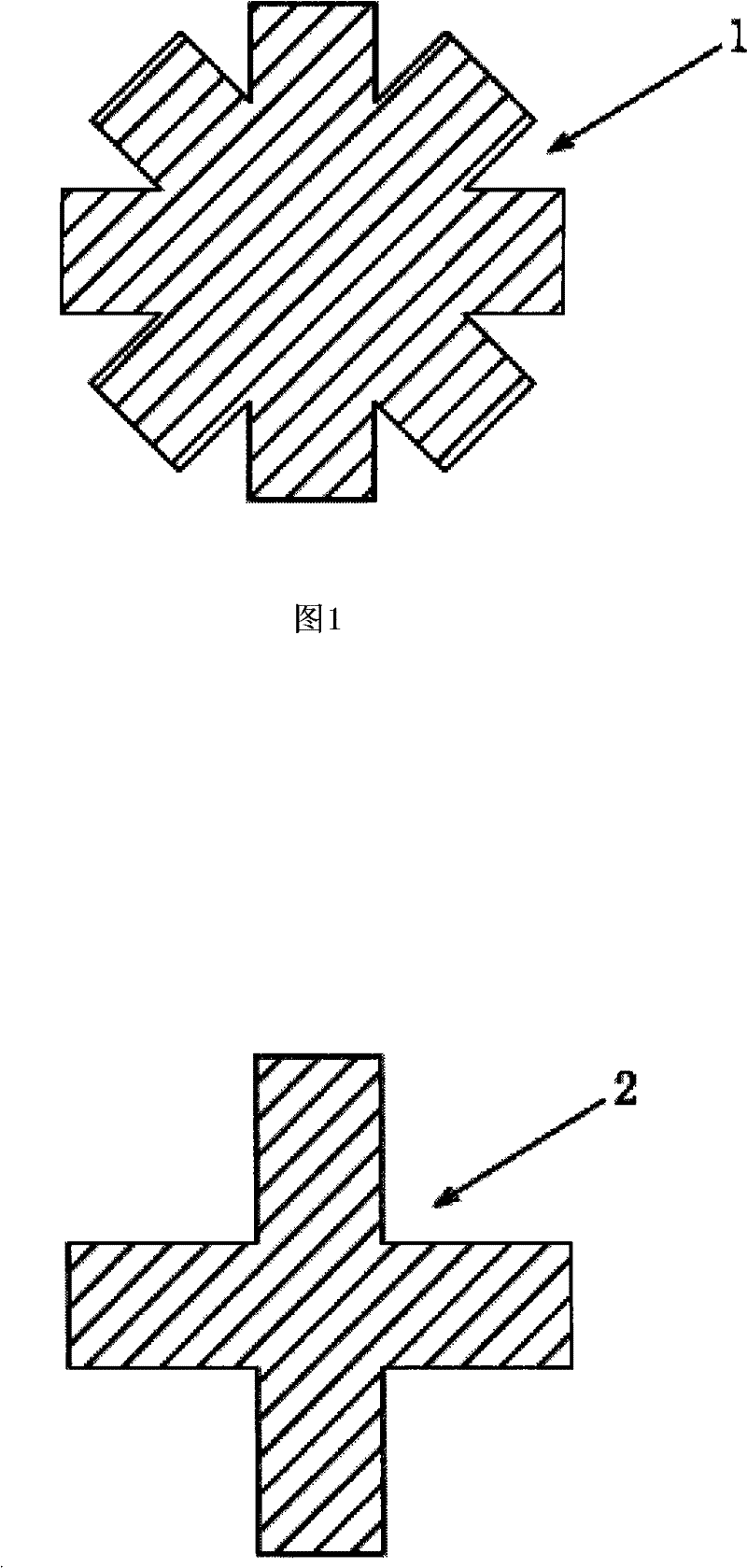

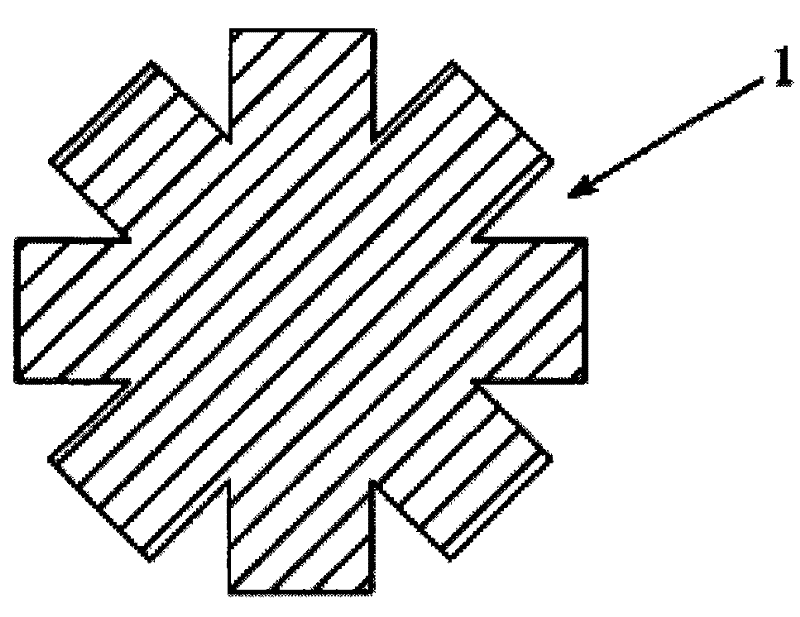

Different shrinkage two-component network composite filament

The invention discloses a different shrinkage two-component network composite filament, which consists of a pre-oriented yarn and a fully draw yarn, the pre-oriented yarn is composed of 8-144 filament fibers, and the section of the pre-oriented yarn is shaped like a Chinese character Mi, and the fully draw yarn is composed of 8-96 filament fibers, and the section of the fully draw yarn is cross-shaped, and the embodiment has good evenness on running thread and uniform dyeing, and has effects of moisture absorption and perspiration.

Owner:XUZHOU SILK FIBER TECH

A preparation method of multi-component variable structure functional sports socks

The invention discloses a manufacturing method of multi-component variable-structure functional sports socks. According to the multi-component variable-structure functional sports socks, short ultra-high molecular weight polyethylene fibers, Coolmax, hemp and other functional fibers and traditional raw materials are combined and used for weaving of different portions of the socks respectively, reasonable organization structure design is conducted on the different portions of the socks, and sock blanks are woven through a computer hosiery machine, and then shaped and arranged. The manufactured multi-component variable-structure functional sports socks containing the short ultra-high molecular weight polyethylene fibers, the Coolmax, the hemp and other functional fibers have the advantages of being capable of absorbing moisture, exhausting sweat and achieving deodorization, resistant to bacteria and abrasion, comfortable to wear and the like, and can completely meet the requirements of high-grade sports socks for integrating the functions of comfort, sanitation, healthcare, wear resistance and the like.

Owner:IANGSU COLLEGE OF ENG & TECH

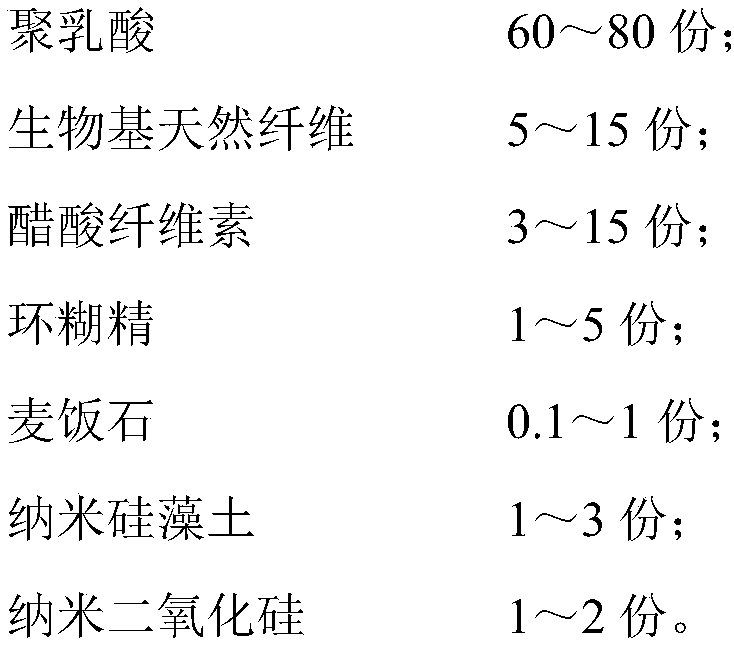

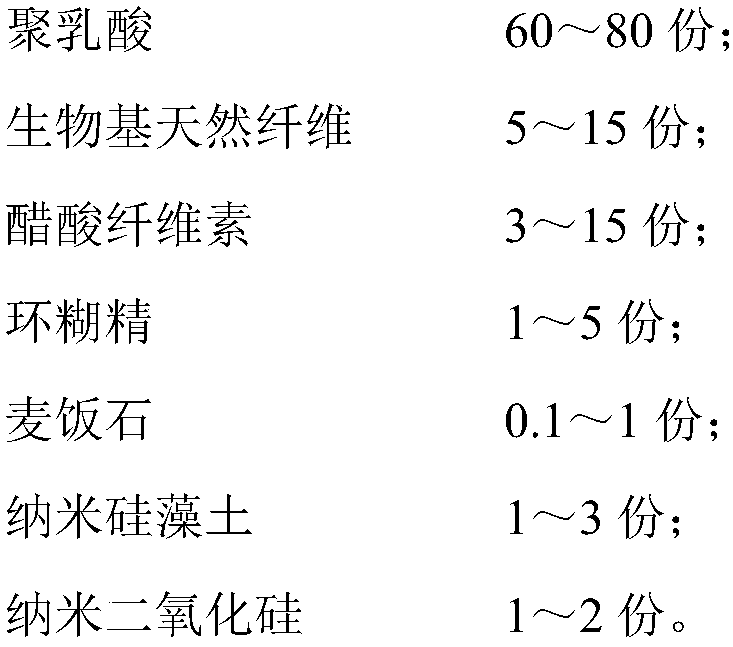

Novel polylactic acid fibers as well as preparation method and application thereof

ActiveCN108301067ABreathableWith perspirationGarment special featuresMonocomponent polyesters artificial filamentCellulose acetateCyclodextrin

The invention relates to the technical field of new textile materials, in particular to novel polylactic acid fibers as well as a preparation method and application thereof. The novel polylactic acidfibers are at least prepared from the following preparation raw material components: 60-80 parts of polylactic acid; 5-15 parts of bio-based natural fibers, 3-15 parts of cellulose acetate, 1-5 partsof cyclodextrin, 0.1-1 part of medical stone, 1-3 parts of nano-diatomite and 1-2 parts of nano-silica.

Owner:浙江施维康生物医学材料有限公司

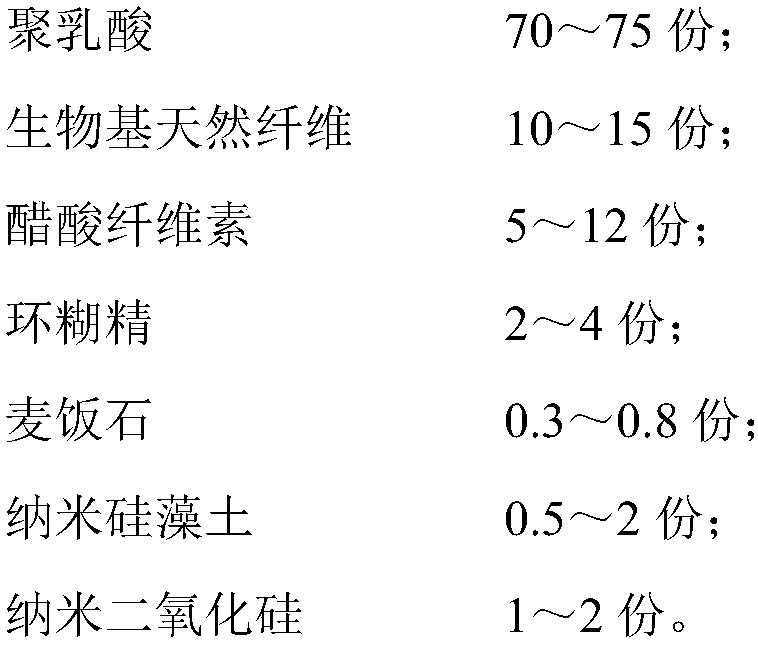

Multifunctional protective glasses

InactiveCN106033151AHigh light transmittancePrevent splashNon-optical partsOptical partsUses eyeglassesEyewear

The invention provides multifunctional proactive glasses. The glasses comprise glasses lens, in-built glasses supports, nose pads, an elastic fixing belt, ventilation devices, an adjustable fixing buckle, silica gel protective glasses, and a glasses frame. The glasses frame is arranged between the lens and the silica gel protective glasses. The left and right of the center of the upper part of the glasses frame are both provided with an in-built glasses support. The left and right of the center of the lower part of the glasses frame are both provided with a nose pad. Four ventilation devices are arranged on the glasses frame. The upper surfaces and lower surfaces of lens are all provided with a ventilation device. By setting the lens, in-built glasses supports, ventilation devices, and adjustable fixing buckle, the provided multifunctional protective glasses can solve the problems that the conventional multifunctional protective glasses cannot meet the requirements of people, although the multifunctional protective glasses have multiple functions; the elastic fixing belt cannot be adjusted according to the size of head; the people who wear glasses are not taken into account, the conventional multifunctional protective glasses are not suitable for overall popularization therefore; and the ventilation effect of the conventional multifunctional protective glasses is not good.

Owner:YONGAN TIANJIN OCCUPATIONAL HEALTH EXAMINATION & EVALUATION

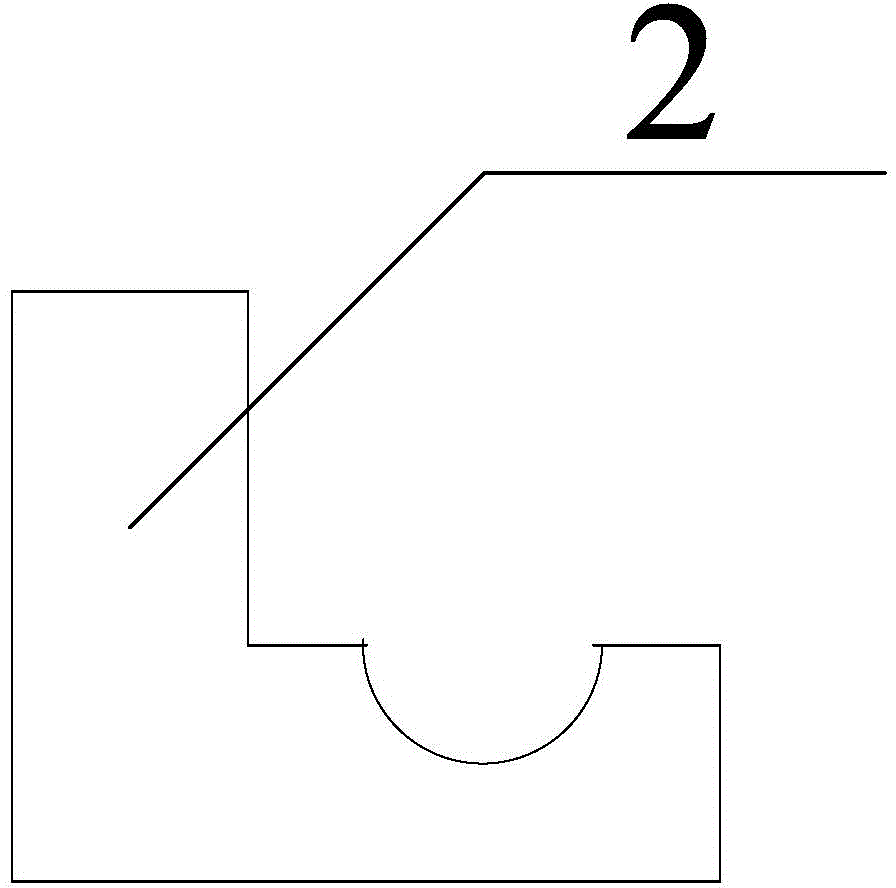

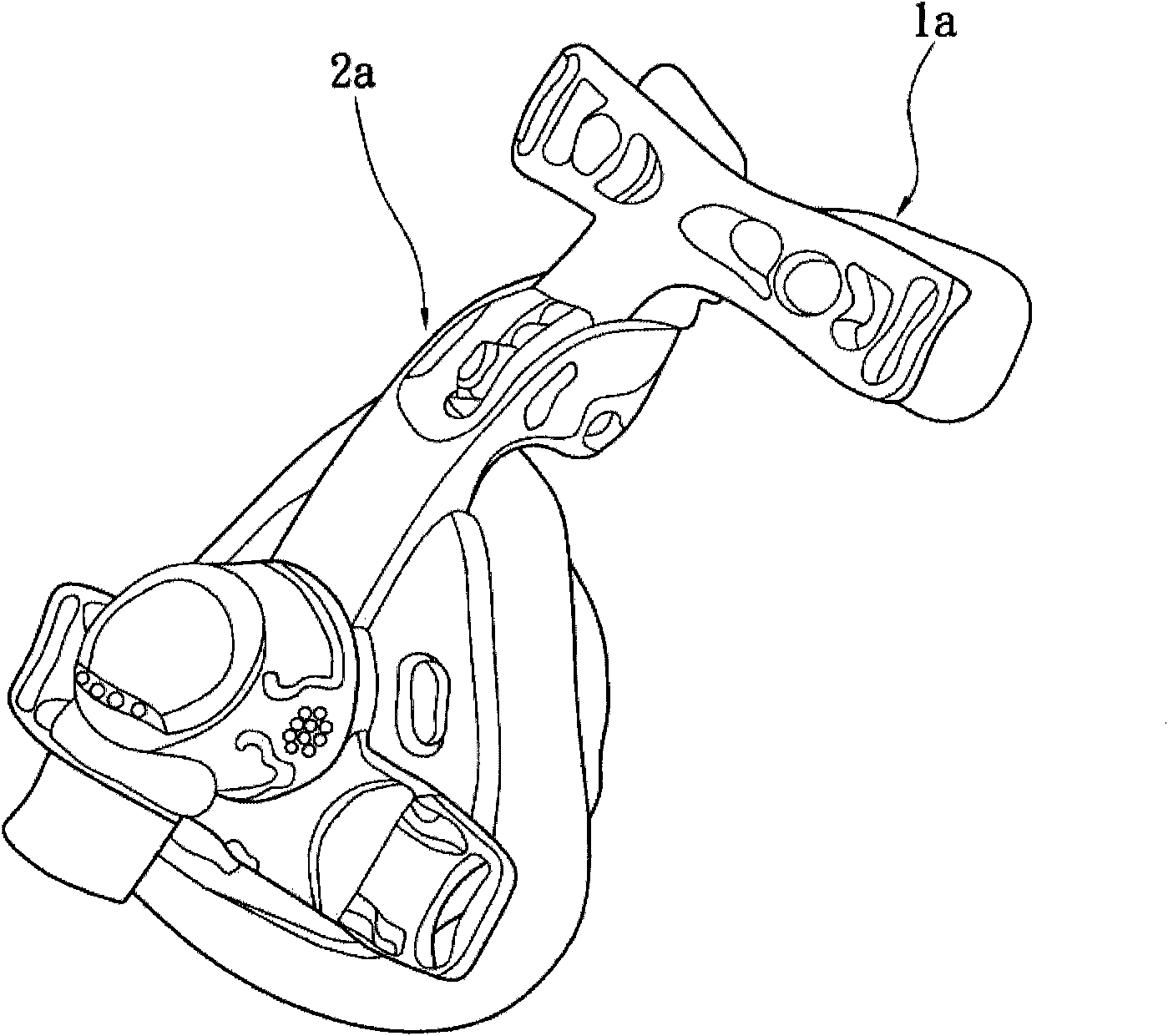

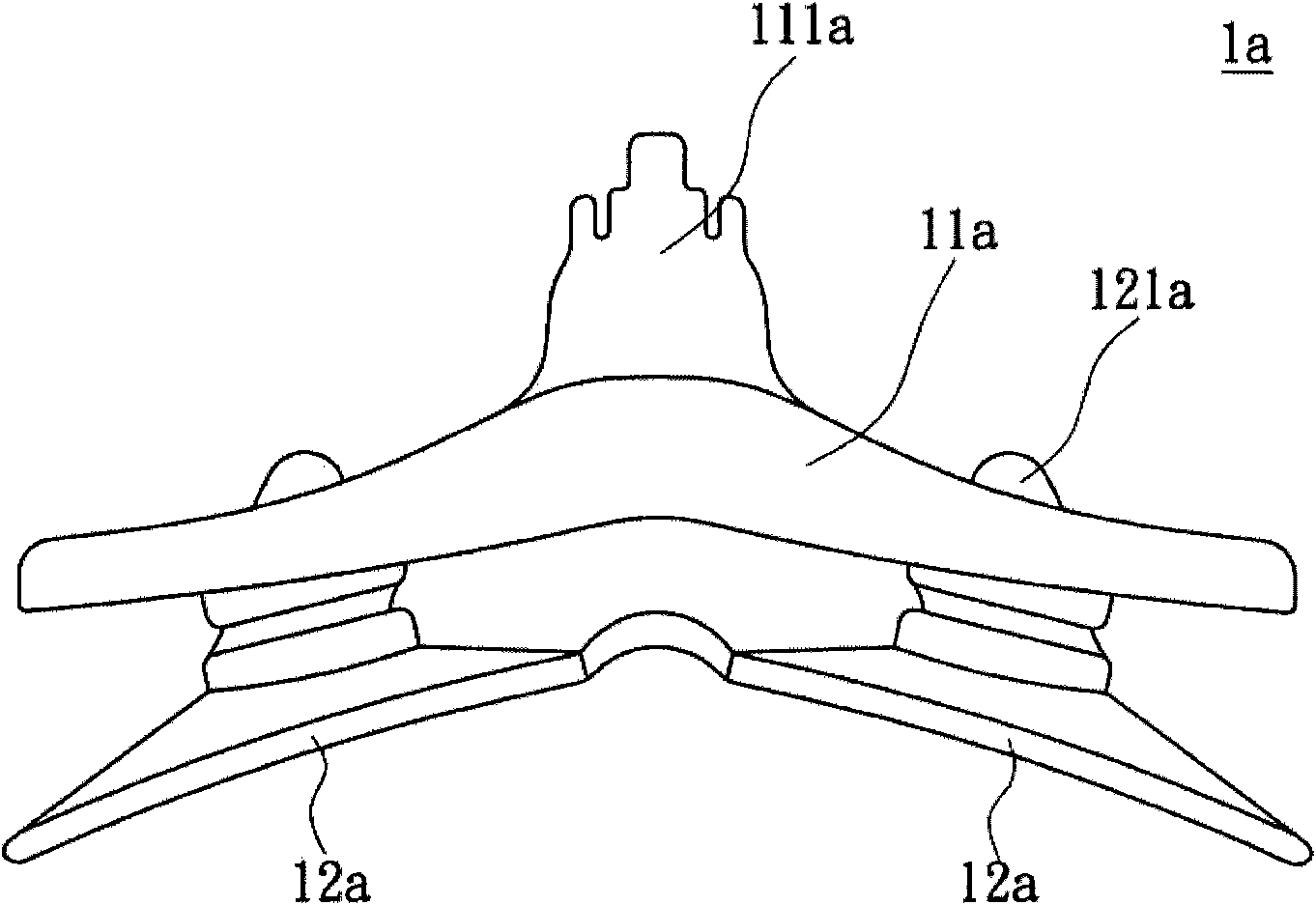

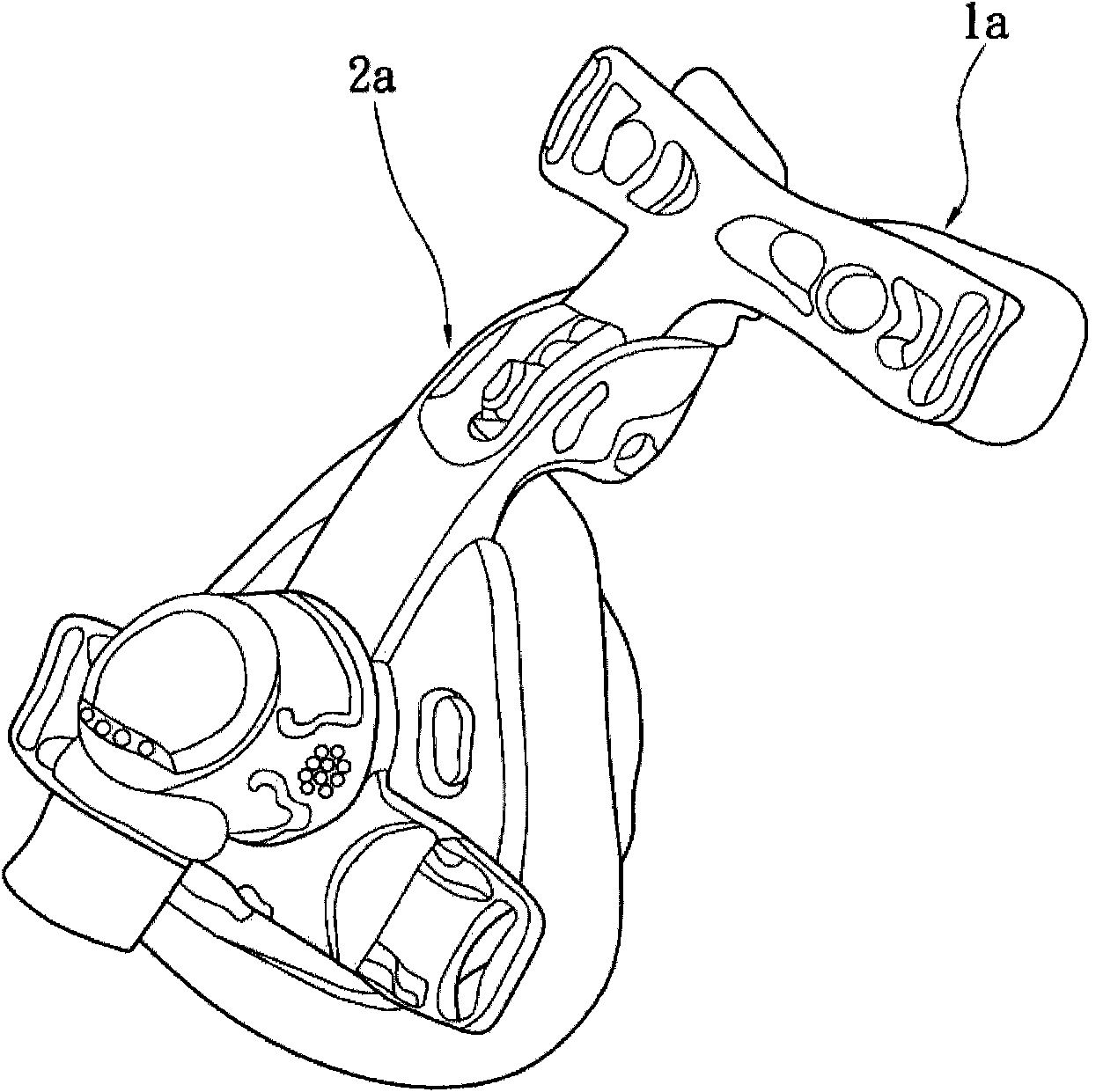

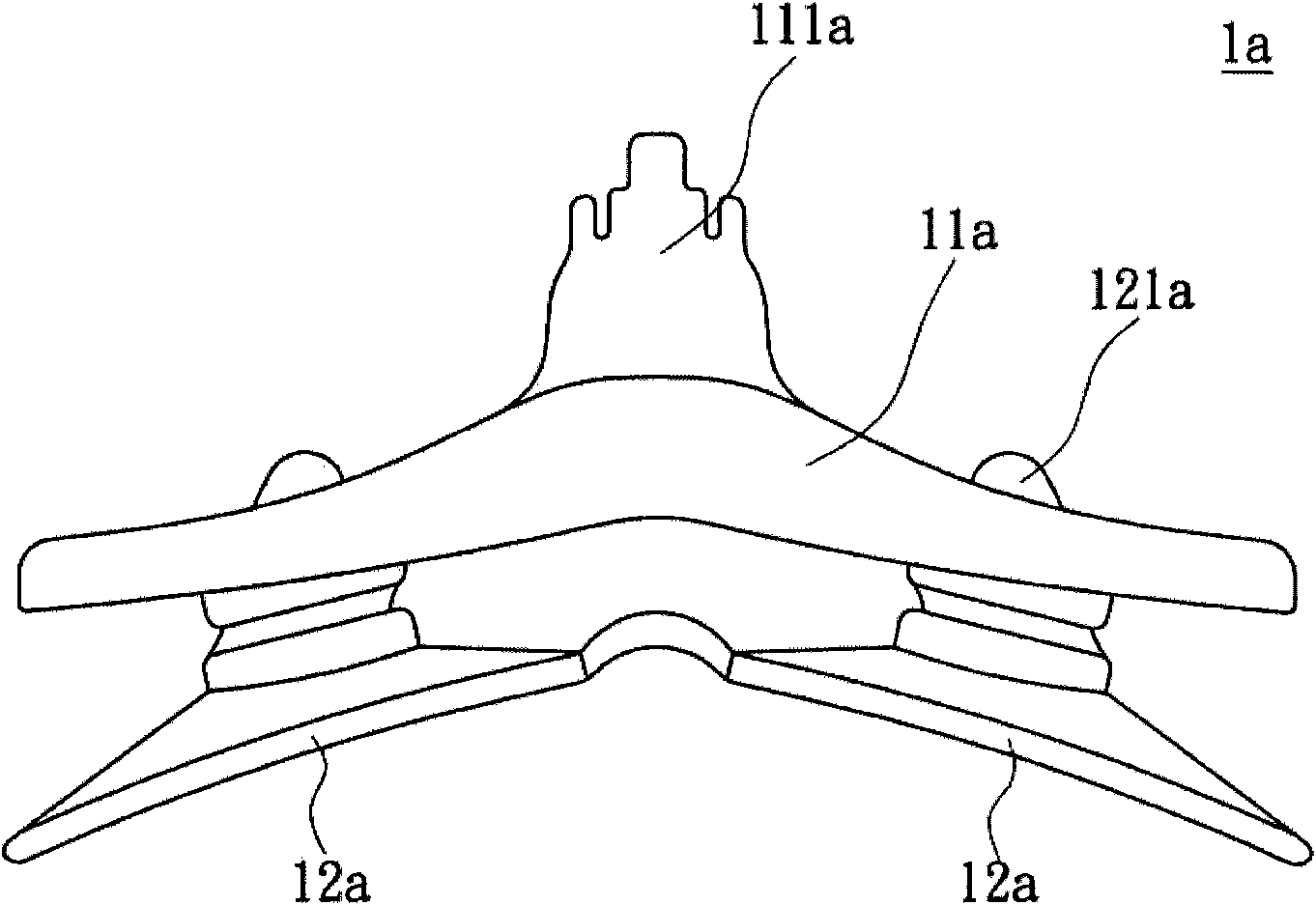

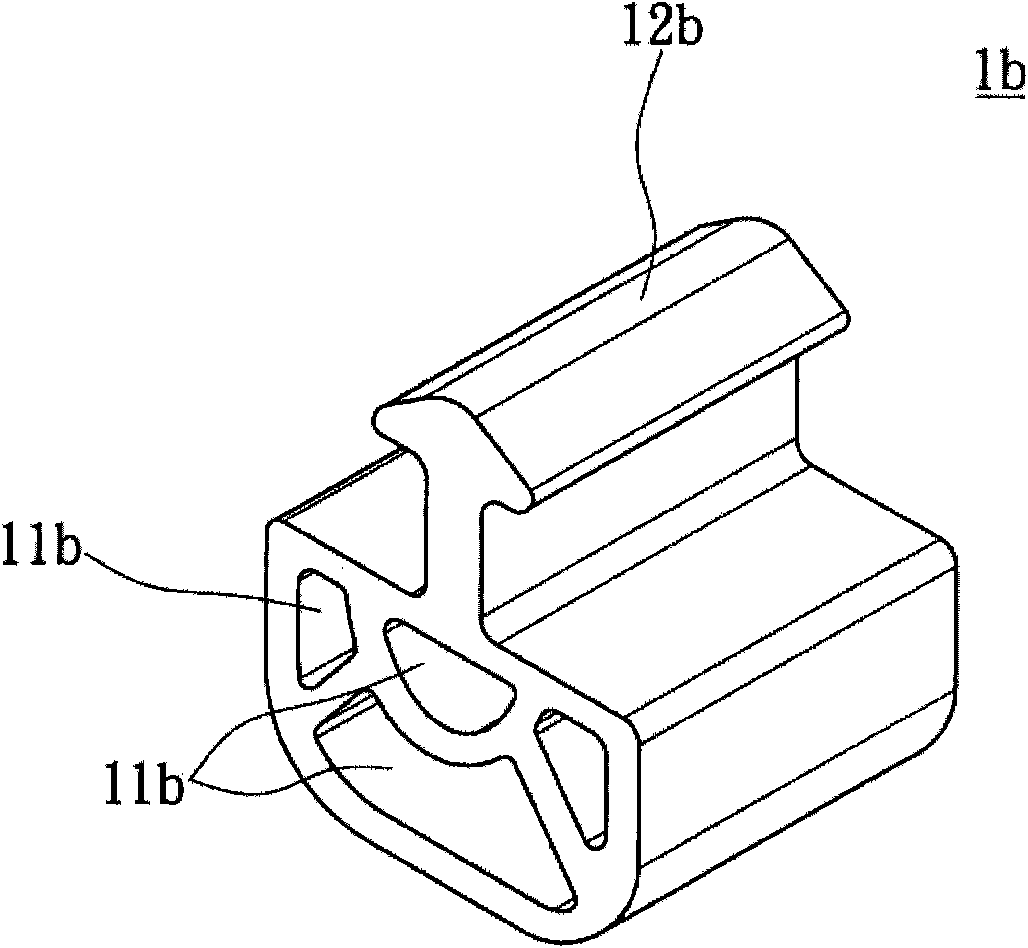

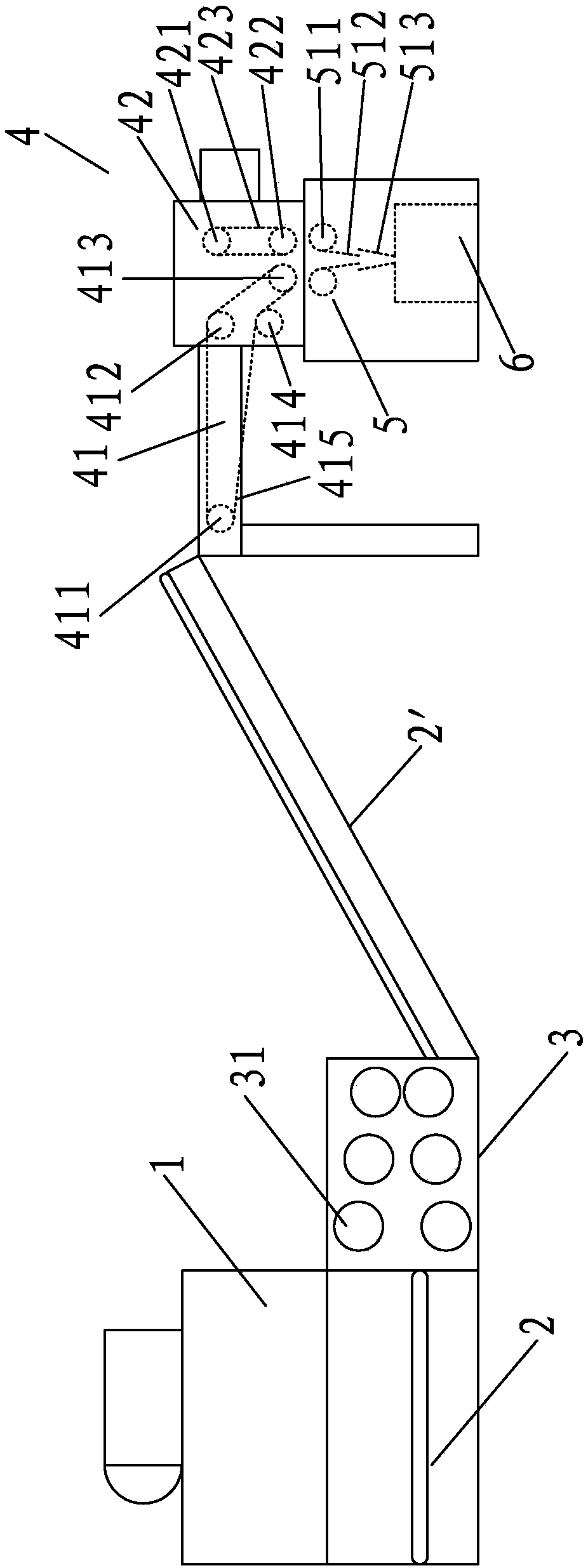

Replaceable forehead pad for positive pressure breathing mask

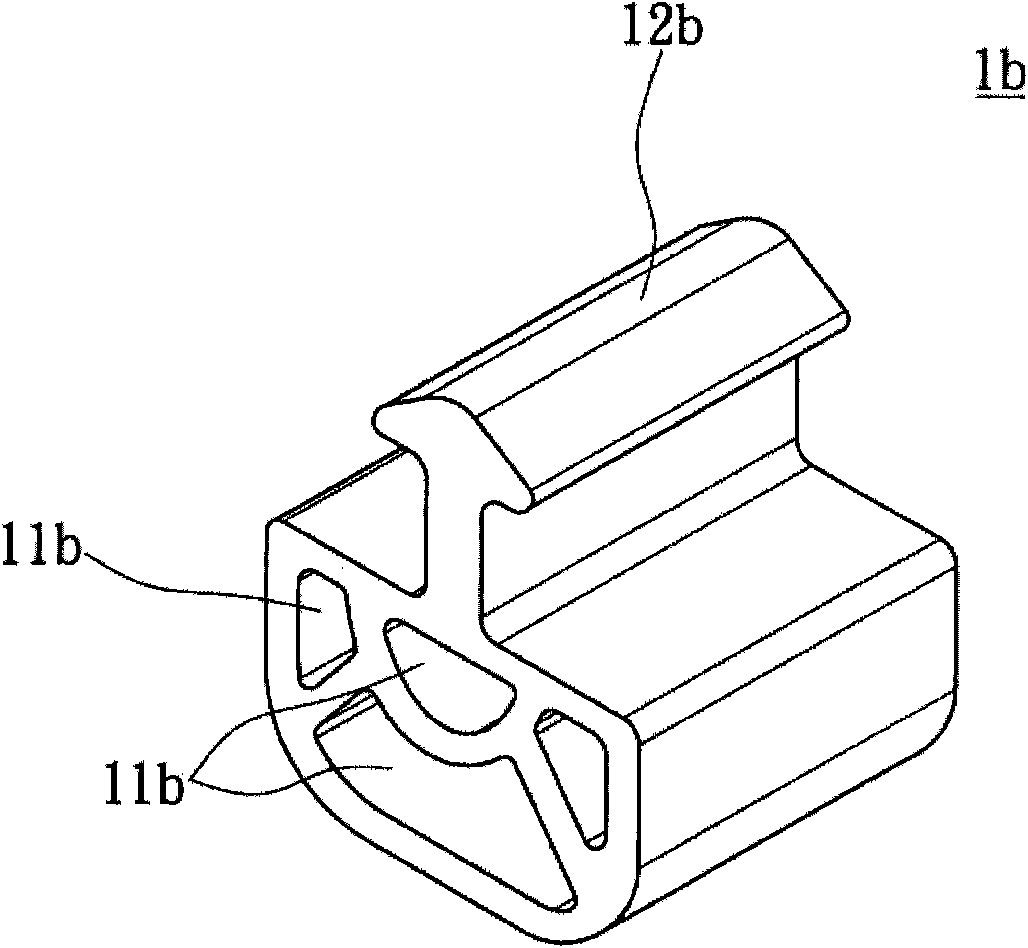

The invention discloses a replaceable forehead pad for a positive pressure breathing mask. The replaceable forehead pad comprises a substrate part, a support part and a buckling body; the substrate part is provided with two contact sheet bodies and a connection arm which is used for connecting two contact sheet bodies; the support part is provided with two support bodies and a plate arm which is connected with the two support bodies; a hollow area is formed among the support bodies, the plate arm and the contact sheet bodies and a hollow hole is formed on each support body to ensure that the support bodies can be flexibly compressed to be deformed; the buckling body is extended from the surfaces of two support bodies and the plate arm, and the long side of the buckling body is longer than the long side of the formed hollow area; the buckling body is provided with buckling parts; the buckling parts, and buckled parts of a mask device of the positive pressure breathing mask can be buckled and assembled; therefore, the replaceable forehead pad can be buckled conveniently and reduce the falling risk, and structural intensity and stress dispersing can be enhanced so as to reduce stress discomfort.

Owner:APEX MEDICAL CORPORATION

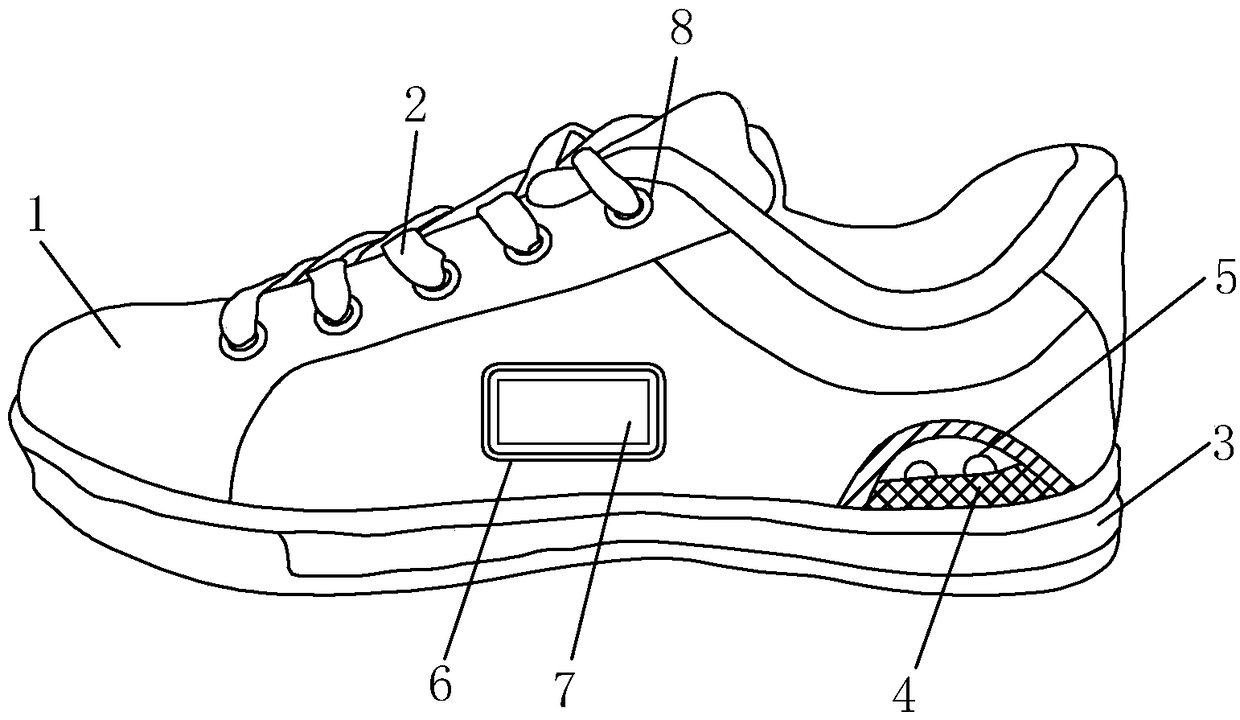

Damping comfortable female fashion shoe and processing process thereof

The invention relates to the technical field of shoemaking, in particular to a damping comfortable female fashion shoe. The damping comfortable female fashion shoe comprises a shoe sole and a vamp. The vamp is sewn at the upper end of the shoe sole. A damping insole is laid on the upper surface of the shoe sole. A plurality of shoelace holes running through the vamp are formed in the vamp, and thedistances between the adjacent shoelace holes are the same. A shoelace penetrates through the shoelace holes. The damping insole comprises a sweat absorbing layer, a buffering layer and a supportinglayer. The supporting layer is located on the upper surface of the shoe sole. The supporting layer is a rubber layer specifically. The buffering layer is sewn on the upper surface of the supporting layer. The buffering layer is a fluff layer specifically. The sweat absorbing layer is sewn on the upper surface of the buffering layer. The sweat absorbing layer is a bamboo fiber layer specifically. The thickness ratio of the sweat absorbing layer to the buffering layer to the supporting layer is 1:1:2. The made shoe is environmentally friendly, light in weight and good in damping effect and meanwhile has collection value.

Owner:浙江漂亮家族鞋业有限公司

A kind of ultra-thin polytetrafluoroethylene film fabric and its embossing process

ActiveCN104325767BReduce weightWith windshieldLamination ancillary operationsSynthetic resin layered productsPolymer scienceBoPET

Owner:HUZHOU SENNUO FLUORINE MATERIAL TECH

Replaceable forehead pad for positive pressure breathing mask

InactiveCN102371020BReduce oppressionImprove use comfort performanceRespiratory masksFall riskEngineering

The invention discloses a replaceable forehead pad for a positive pressure breathing mask. The replaceable forehead pad comprises a substrate part, a support part and a buckling body; the substrate part is provided with two contact sheet bodies and a connection arm which is used for connecting two contact sheet bodies; the support part is provided with two support bodies and a plate arm which is connected with the two support bodies; a hollow area is formed among the support bodies, the plate arm and the contact sheet bodies and a hollow hole is formed on each support body to ensure that the support bodies can be flexibly compressed to be deformed; the buckling body is extended from the surfaces of two support bodies and the plate arm, and the long side of the buckling body is longer than the long side of the formed hollow area; the buckling body is provided with buckling parts; the buckling parts, and buckled parts of a mask device of the positive pressure breathing mask can be buckled and assembled; therefore, the replaceable forehead pad can be buckled conveniently and reduce the falling risk, and structural intensity and stress dispersing can be enhanced so as to reduce stress discomfort.

Owner:APEX MEDICAL CORPORATION

A kind of environment-friendly thickened seam-knitted Lixin cloth, its production process and an insole

Owner:特斯(中国)有限公司

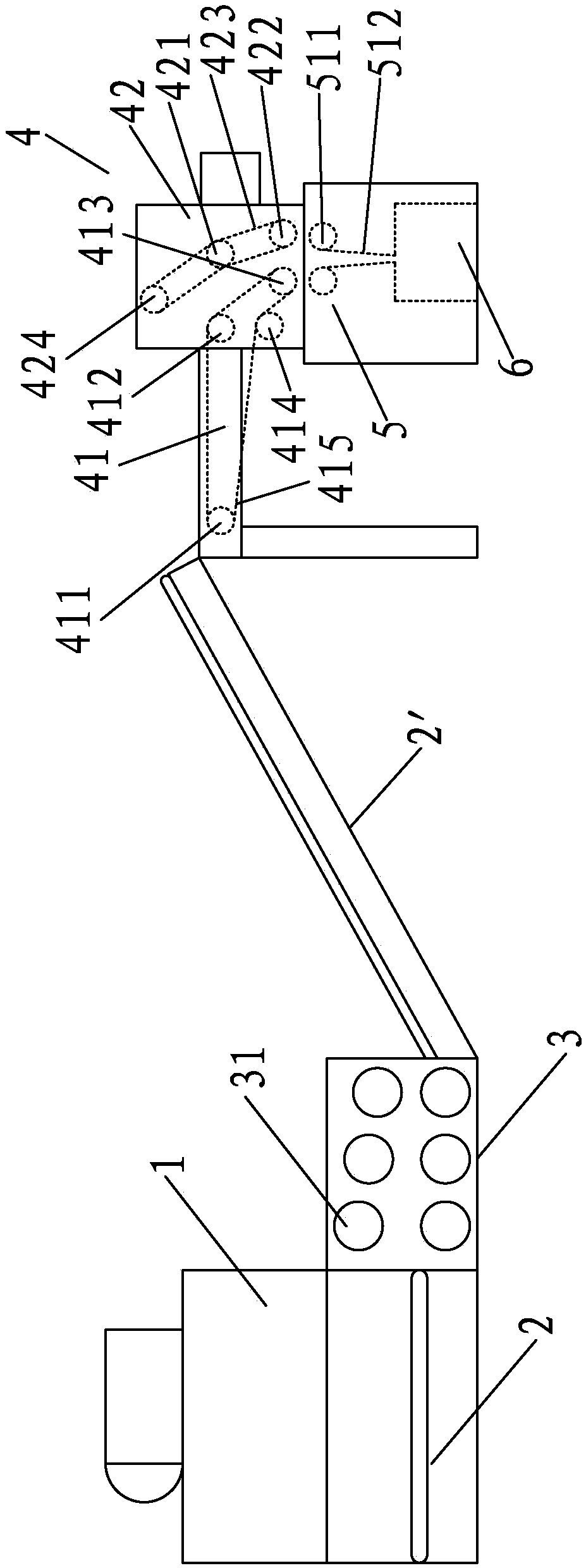

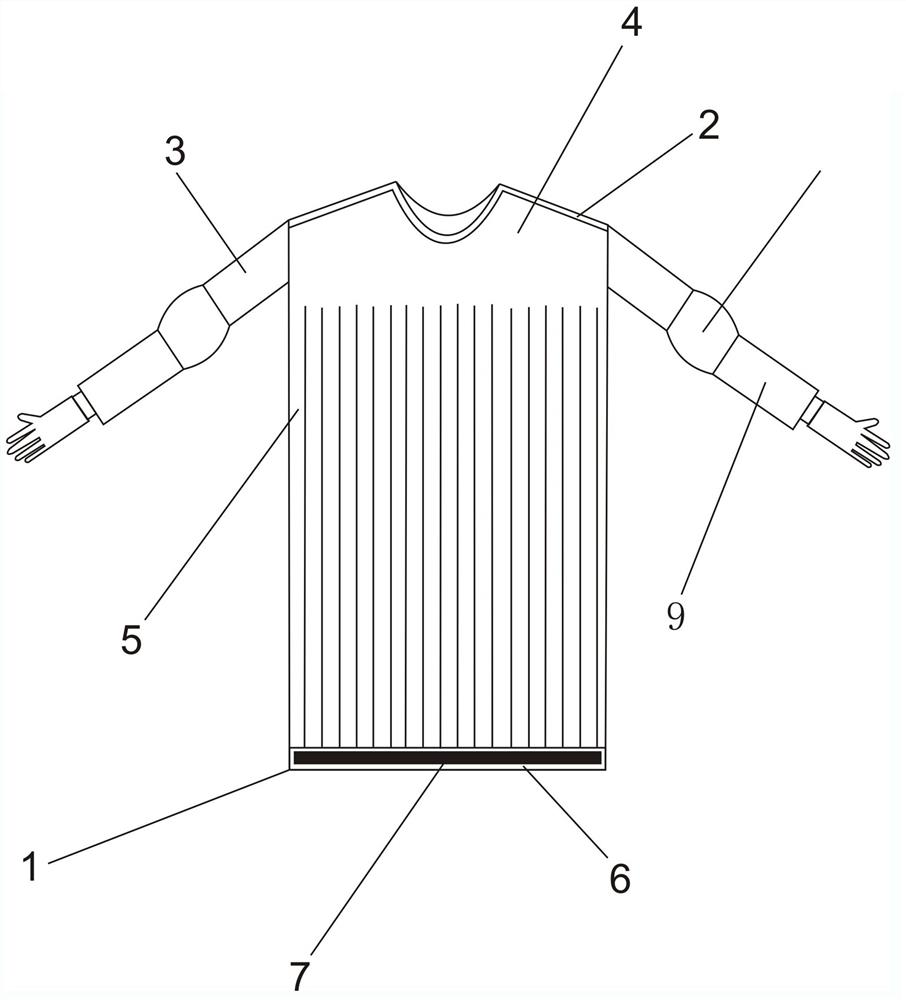

Anti-static surgical gown

InactiveCN111820506ASimple structureAnti-staticProtective garmentSpecial outerwear garmentsSurgical GownsReoperative surgery

The invention relates to an anti-static surgical gown, which is composed of a gown body, the gown body is composed of a gown main body and sleeves, and the anti-static surgical gown is simple in structure and has the functions of preventing static electricity, absorbing moisture, releasing sweat, deodorizing, ventilating, resisting mildew, sterilizing, preventing permeation and the like.

Owner:安庆德迪康医疗科技有限公司

Different shrinkage two-component network composite filament

The invention discloses a different shrinkage two-component network composite filament, which consists of a pre-oriented yarn and a fully draw yarn, the pre-oriented yarn is composed of 8-144 filament fibers, and the section of the pre-oriented yarn is shaped like a Chinese character Mi, and the fully draw yarn is composed of 8-96 filament fibers, and the section of the fully draw yarn is cross-shaped, and the embodiment has good evenness on running thread and uniform dyeing, and has effects of moisture absorption and perspiration.

Owner:XUZHOU SILK FIBER TECH

Multifunctional Massage Socks

ActiveCN106690441BWith anti-skid functionAvoid squeezingElectrotherapyDevices for pressing relfex pointsPerspirationReticular formation

The invention provides a multi-functional massage stock which comprises a sock body. A thickening mat toe ring is arranged on the head of the sock body; a plurality of toe care blocks are placed on the front side of the mat toe ring, a former thickening layer is placed at the bottom of the front foot of the sock body, and a back thickening layer is placed at the back foot of the sock body. The sole part between the former thickening layer and the back thickening layer is network-like, and the instep part of the sock body is network-like. The network-like structure of the instep part is provided with a plurality of circular massage bosses, and toe covers are placed outside the toe care blocks. A user feels more skin-friendly and comfortable when wearing the sock, and a series of problems such as foot massage, health care, ventilation, perspiration, smelly feet and the like are solved.

Owner:辽源隆鑫源纺织贸易有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com