Tencel and T400 jean stretch fabric

A Tencel and denim technology, which is applied in fabrics, textiles, textiles, and papermaking, can solve the problems of trouser knee blistering, itchy skin, and unstable dimensions, and achieve soft hand feeling, good drapability, and stable dimensions. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

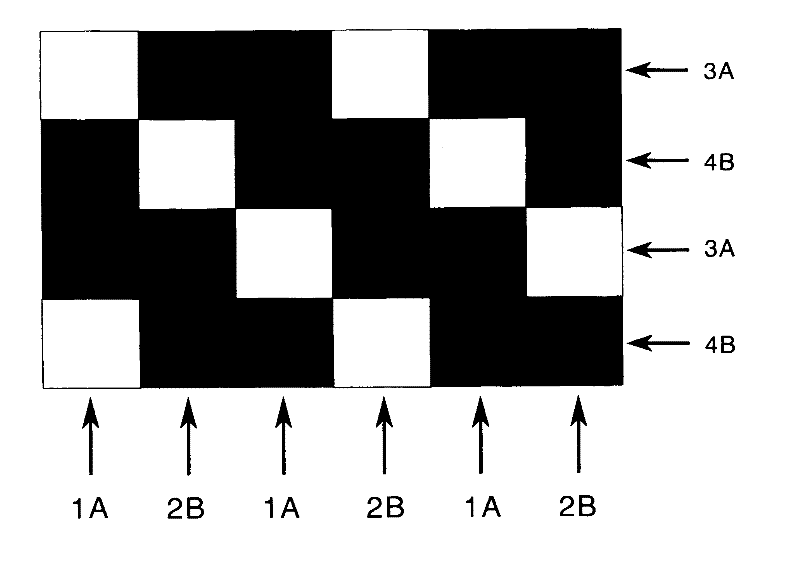

[0011] figure 1 As shown, the vertical grid represents the longitude, and the horizontal grid represents the latitude.

[0012] For Tencel and T400 denim stretch fabrics, the warp and weft threads are interwoven two times up and down to form a left twill weave. The warp threads include A warp thread and B warp thread; the weft threads include A weft thread and B weft thread.

[0013] In the present invention, the A warp is selected from 21S tencel fiber yarn, the B warp is selected from 18S tencel slub yarn; the A weft is selected from 150D T400 fiber, and the B weft is selected from 68D metal sequins and 150D polyester filament machine bag.

[0014] The A meridian and the B meridian are arranged in a ratio of 2:1;

[0015] The A weft and B weft are arranged in a ratio of 1:1.

[0016] The grammage of the warp is 250g / m, and the grammage of the weft is 110.2g / m.

[0017] The warp density is 540 threads / 10cm, and the weft density is 240 threads / 10cm.

[0018] A warp, B warp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com