Standard self-locking liquid distribution pump with spring arranged outside

A dispensing pump and self-locking technology, applied in the direction of liquid injection device, injection device, single handheld device, etc., can solve the problems that the components of the pump system cannot be made into standard components, the pump system cannot be assembled, and the assembly cost is increased. It can achieve the effect of convenient and quick connection, improve spray effect and prevent liquid leakage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

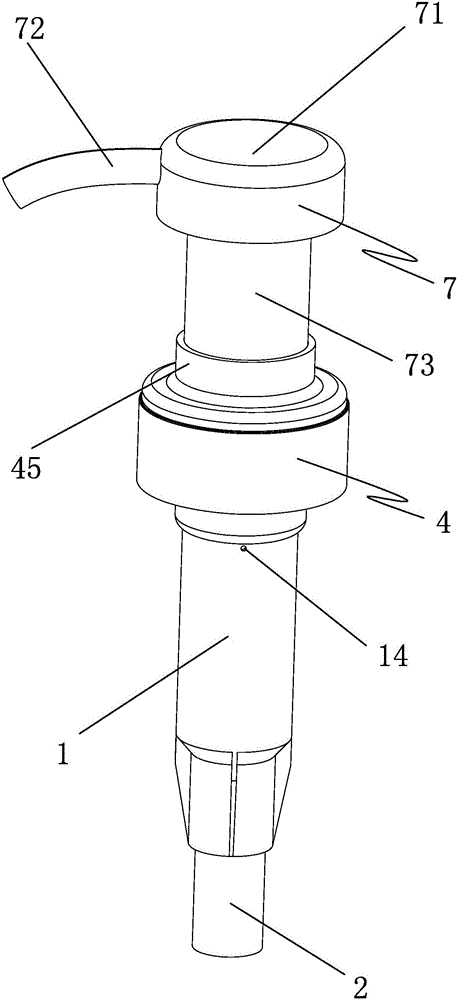

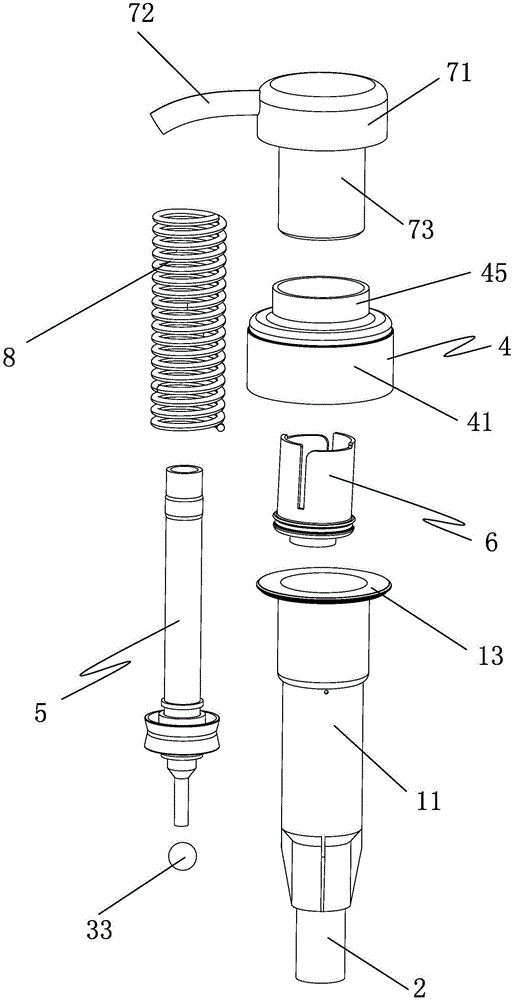

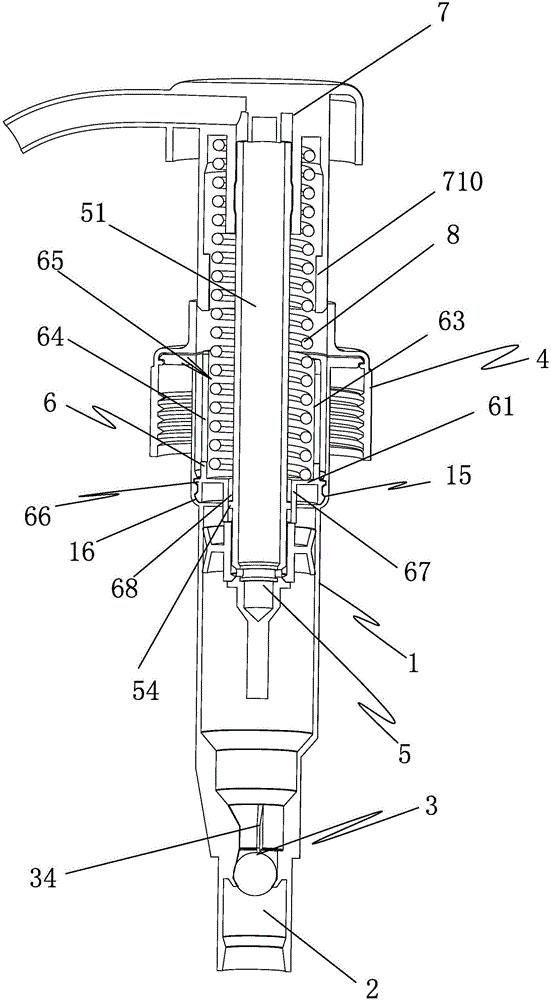

[0035] The present invention will be further described below in conjunction with accompanying drawing description and specific embodiment:

[0036] Such as Figures 1 to 11 The shown standardized self-locking liquid dispensing pump with an external spring includes a pump chamber 1, and a pump bead mechanism 3 capable of closing the liquid inlet port 2 at the lower end of the pump chamber 1 is arranged in the lower part of the pump chamber 1. The upper end of the chamber 1 is provided with a bottle lock cap 4, which is characterized in that: an integrated suction plug pump rod mechanism 5 is provided in the pump chamber 1, and an integrated suction plug pump rod mechanism 5 is provided in the upper part of the pump chamber 1 to prevent the integrated suction plug pump rod from The mechanism 5 is separated from the self-locking locking cover 6 of the pump chamber 1. The self-locking locking cover 6 includes a locking cover body 61, and a connecting hole 62 is provided in the mid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com