Preparation method of complete micro-ecological feed containing farmland by-products for ruminant animals

A micro-ecological feed and ruminant technology, applied in animal feed, animal feed, applications, etc., can solve the problems of difficult to increase animal dry matter intake, difficult to achieve nutritional balance, low absorption rate, etc., to improve comprehensive feeding value, achieving standardized production, and increasing feed intake

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

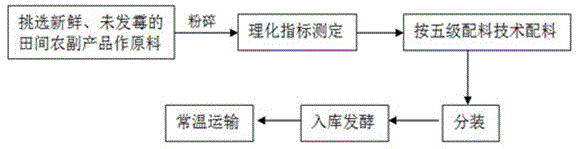

Method used

Image

Examples

Embodiment 1

[0027] Example 1 : preparing a full-price micro-ecological feed for ruminants containing pumpkin pulp and corn cobs, the preparation method comprising the following steps:

[0028] (1) Weighing: Take 1000Kg of pumpkin pulp and 500Kg of corncob;

[0029] (2) Crush: Beat the pumpkin pulp and crush the corn cob for later use;

[0030] (3) Determination of physical and chemical indicators: Sampling and testing the physical and chemical indicators of the beaten pumpkin pulp and crushed corncobs;

[0031] (4) Ingredients: The following five-level ingredients are used

[0032] The first level: take 1000 Kg of the above-mentioned pumpkin pulp and 500 Kg of corn cobs and mix them to make a mixed roughage;

[0033] The second level: Take the following raw materials to prepare mixed concentrate feed: 50 Kg of soybean meal, 20 Kg of cotton meal, 25 Kg of rapeseed meal, 5 Kg of compound trace elements,

[0034] The third level: Take the following raw materials to prepare fermentation ...

Embodiment 2

[0041] Example 2 : preparing a full-price micro-ecological feed for ruminants containing pumpkin pulp and sunflower heads, the preparation method comprising the following steps:

[0042] (1) Weighing: Take 1000 Kg of pumpkin pulp and 500 Kg of sunflower head;

[0043] (2) Crush: Beat the pumpkin pulp and crush the sunflower head for later use;

[0044] (3) Determination of physical and chemical indicators: Sampling and testing the physical and chemical indicators of pumpkin pulp and sunflower heads after beating and crushing;

[0045] (4) Ingredients: The following five-level ingredients are used:

[0046] The first level: take 1000 Kg of the above-mentioned pumpkin pulp and mix 500 Kg of sunflower heads to make mixed roughage;

[0047] The second level: Take the following raw materials to prepare mixed concentrate feed: 50 Kg of soybean meal, 20 Kg of cotton meal, 25 Kg of rapeseed meal, 5 Kg of compound trace elements,

[0048] The third level: Take the following raw ma...

Embodiment 3

[0055] Example 3 : preparing a full-price micro-ecological feed for ruminants containing pumpkin pulp and sunflower heads, the preparation method comprising the following steps:

[0056] (1) Weighing: Take 1000 Kg of pumpkin pulp and 500 Kg of sunflower head;

[0057] (2) Crush: Beat the pumpkin pulp and crush the sunflower head for later use;

[0058] (3) Determination of physical and chemical indicators: Sampling and testing the physical and chemical indicators of pumpkin pulp and sunflower heads after beating and crushing;

[0059] (4) Ingredients: Five-level ingredients are used:

[0060] The first stage: take 1000 Kg of pumpkin pulp and 500 Kg of sunflower head to make mixed roughage;

[0061] The second level: Take the following raw materials to prepare mixed concentrate feed: 10 Kg of soybean meal, 10 Kg of cotton meal, 10 Kg of rapeseed meal, and 0.1 Kg of compound trace elements;

[0062] The third level: Take the following raw materials to prepare fermentation b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com