Novel polylactic acid fibers as well as preparation method and application thereof

A polylactic acid fiber and polylactic acid technology, applied in the fields of application, fiber chemical characteristics, rayon manufacturing, etc., to achieve good drape and elasticity, good elastic recovery rate, and soft hand feeling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0045] The preparation method of the modified medical stone fiber is as follows: the medical stone fiber is added to a sodium stearate solution with a mass fraction of 35%, and at the same time, carbon dioxide is introduced to adjust the pH of the solution to be 6, and the reaction temperature is controlled to be 120° C. , the reaction time is 30min, after filtering and drying, the modified medical stone fiber is obtained.

[0046] In a preferred embodiment, the weight ratio of the medical stone fiber to sodium stearate is 1: (1-3).

[0047] In this application, the "nano diatomite" is commercially available and purchased from Jilin Province Tianyuan Catalyst Co., Ltd.

[0048] In this application, the "nano silicon dioxide" is commercially available and purchased from Nanjing Xianfeng Nano Materials Co., Ltd.

[0049] The "nano silicon dioxide" is nano silicon dioxide treated with KH550.

[0050] The CAS number of the nano silica product treated with KH550: 7631-86-9.

[005...

Embodiment 1

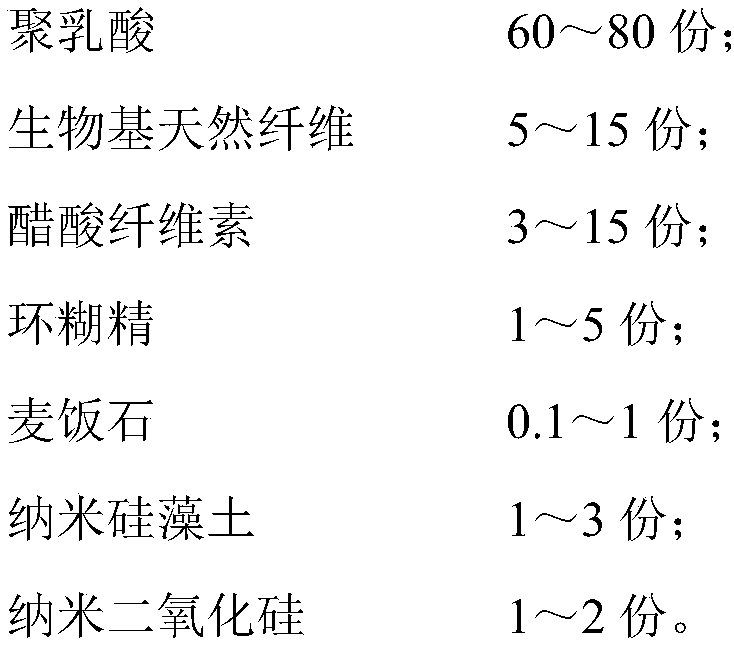

[0070] Embodiment 1 of the present invention provides a kind of novel polylactic acid fiber, the preparation raw material of described novel polylactic acid fiber, comprises the following components at least:

[0071]

[0072] The polylactic acid is short polylactic acid fiber, purchased from Zhejiang Hisun Biomaterials Co., Ltd.;

[0073] The bio-based natural fiber is soybean fiber, purchased from Shanghai Puhua Textile Co., Ltd.;

[0074] The cellulose acetate is cellulose diacetate, purchased from Hubei Yuancheng Saichuang Technology Co., Ltd.;

[0075] The cyclodextrin is a mixture of oligomeric lactic acid beta cyclodextrin and menthol hydroxypropyl beta cyclodextrin;

[0076] In the mixture of oligomeric lactic acid base beta cyclodextrin and menthol hydroxypropyl beta cyclodextrin, the weight ratio of oligomeric lactic acid base beta cyclodextrin and menthol hydroxypropyl beta cyclodextrin is :100:1;

[0077] The cyclodextrin was purchased from Shandong Binzhou Z...

Embodiment 2

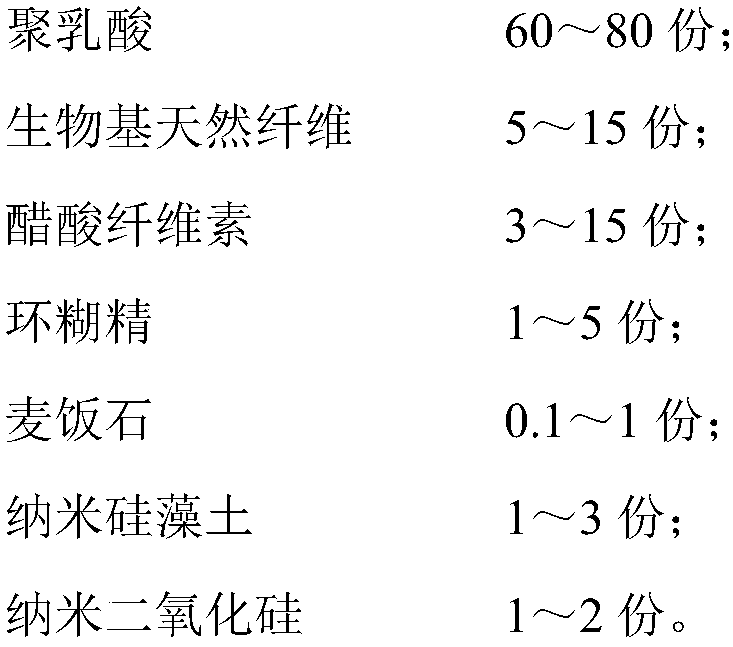

[0088] Embodiment 2 of the present invention provides a kind of novel polylactic acid fiber, the preparation raw material of described novel polylactic acid fiber, comprises the following components at least:

[0089]

[0090] The polylactic acid is short polylactic acid fiber, purchased from Zhejiang Hisun Biomaterials Co., Ltd.;

[0091] The bio-based natural fiber is soybean fiber, purchased from Shanghai Puhua Textile Co., Ltd.;

[0092] The cellulose acetate is cellulose diacetate, purchased from Hubei Yuancheng Saichuang Technology Co., Ltd.;

[0093] The cyclodextrin is a mixture of oligomeric lactic acid beta cyclodextrin and menthol hydroxypropyl beta cyclodextrin;

[0094] In the mixture of oligomeric lactic acid base beta cyclodextrin and menthol hydroxypropyl beta cyclodextrin, the weight ratio of oligomeric lactic acid base beta cyclodextrin and menthol hydroxypropyl beta cyclodextrin is :100:1;

[0095] The cyclodextrin was purchased from Shandong Binzhou Z...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com