A kind of environment-friendly thickened seam-knitted Lixin cloth, its production process and an insole

A production process, environmentally friendly technology, applied in the direction of insoles, footwear, non-woven fabrics, etc., can solve problems such as unreachable, poor air permeability and moisture absorption, and easy structural deformation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

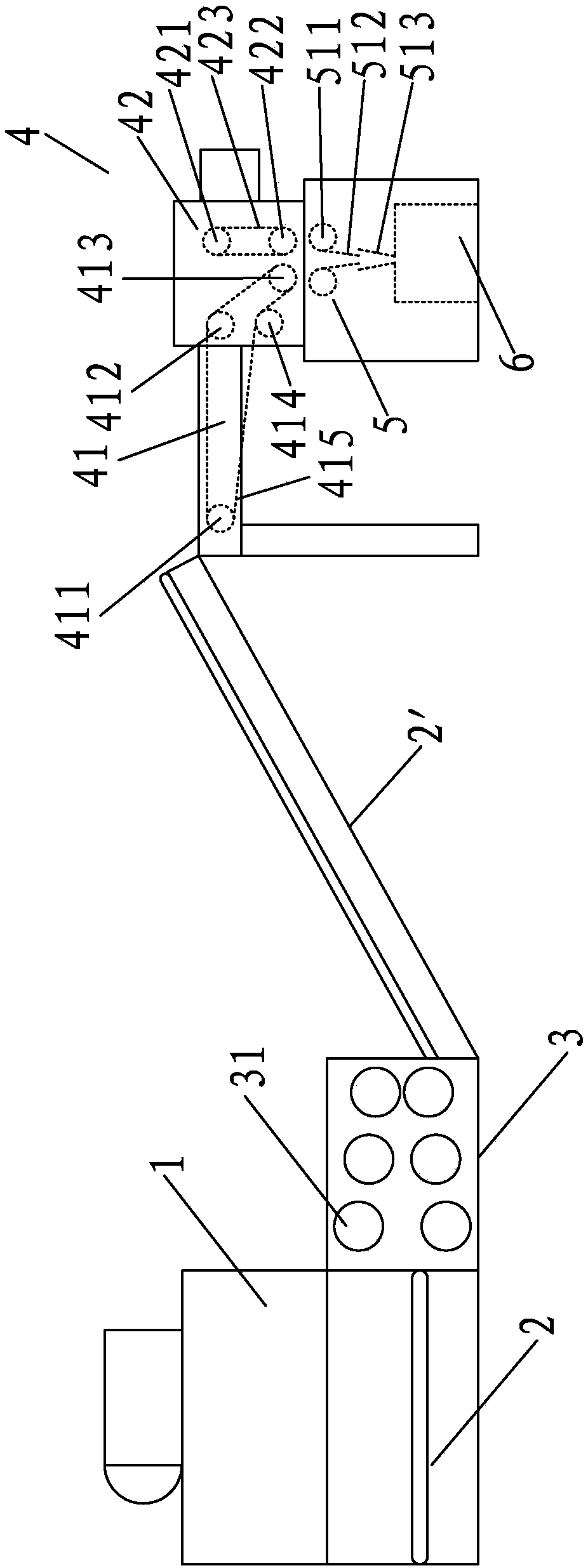

[0063] A kind of production technology of environment-friendly thickened seam-knitted Lixin cloth, such as figure 1 As shown, comprising the following steps: the multi-layer cotton layer is at least sequentially through the following procedures:

[0064] (1) Cotton laying process: multi-layer cotton layer is delivered to compression device by conveyer belt 2 after cotton laying device 1; Wherein, by weight percentage, the raw material of the yarn of braiding cotton layer comprises 80 parts by weight of heat Melt fiber, 80 parts by weight of low-temperature cotton, 20 parts by weight of PET long fibers, and 0.05 parts by weight of nano-scale modified particles.

[0065] (2) Compression process: the laid cotton layer is compressed repeatedly by a compression device, and the total thickness of the cotton layer after each compression is reduced by 15-25%. The compression device consists of the first compression device 3, the second compression device 4 and the third compression d...

Embodiment 2

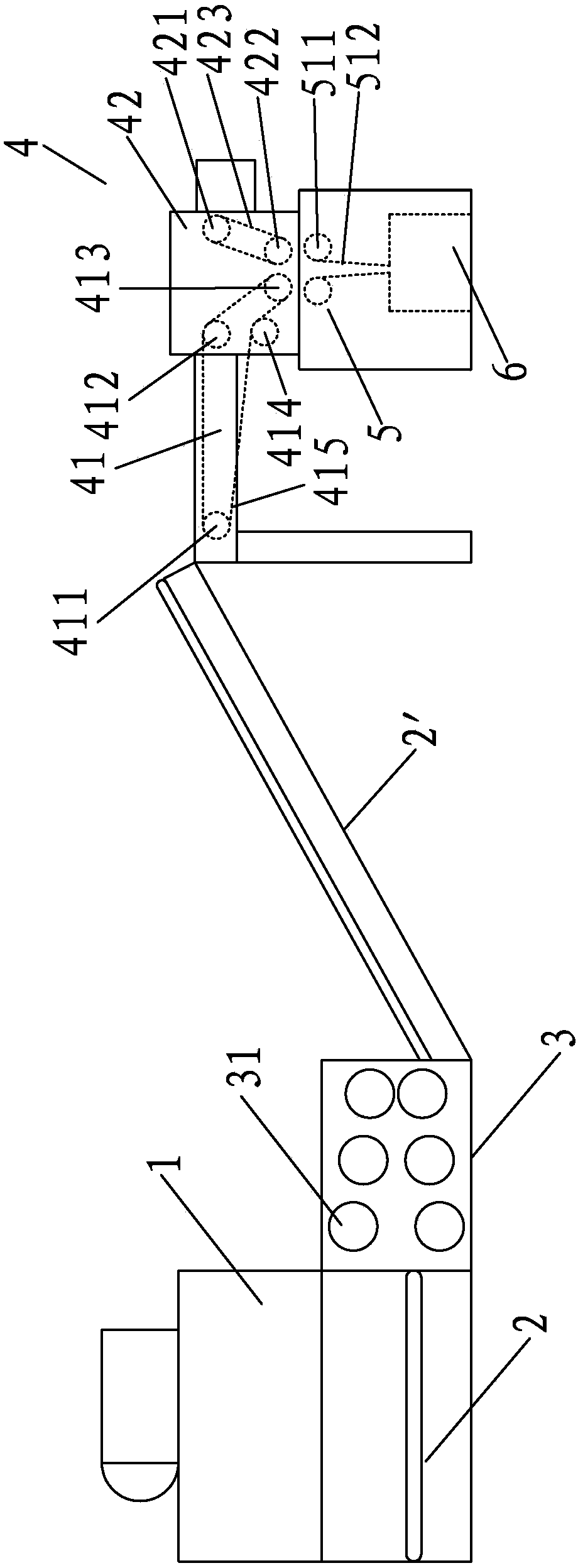

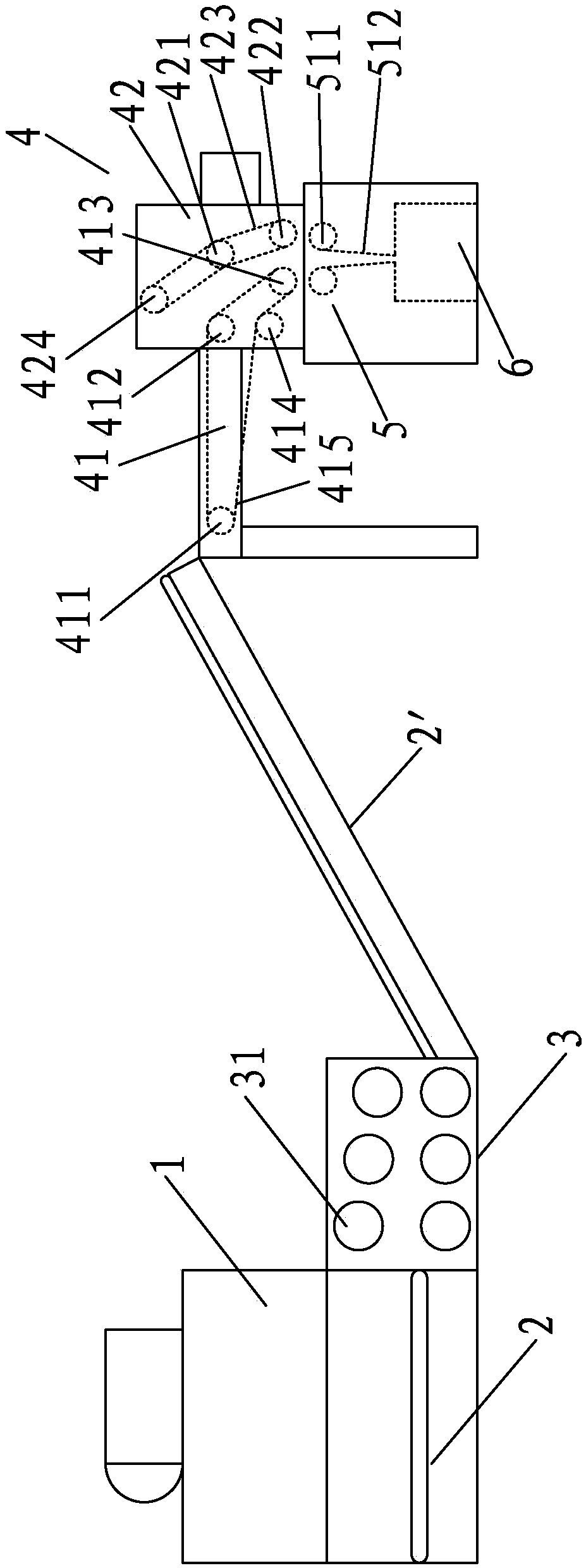

[0072] A kind of production technology of environment-friendly thickened seam-knitted Lixin cloth, such as figure 2 As shown, comprising the following steps: the multi-layer cotton layer is at least sequentially through the following procedures:

[0073] (1) Cotton laying process: multi-layer cotton layer is delivered to compression device by conveyer belt 2 after cotton laying device 1 spreads cotton; Melt fibers, 20 parts by weight of hot-melt cotton, 80 parts by weight of PET short fibers, and 0.05 parts by weight of nano-scale modified particles.

[0074] (2) Compression process: the laid cotton layer is compressed repeatedly by a compression device, and the total thickness of the cotton layer after each compression is reduced by 15-25%. The compression device consists of the first compression device 3, the second compression device 4 and the third compression device 5,

[0075] In the compression process, the first compression device 3 is used for compression. The firs...

Embodiment 3

[0081] an insole such as Figure 4 As shown, the insole body 7 is included, and the insole body is made of the environment-friendly thickened stitch-knitted Lixin cloth. The insole body includes a multi-layer cotton layer, the total thickness of the cotton layer is 0.8-4.5mm, and the cotton layer A plurality of cotton neps which are in contact with the feet are formed on the surface, and the cotton neps are arranged in a concavo-convex pattern on the surface of the insole body in contact with the feet. The insole body of the left foot is provided with a plurality of triangular notches corresponding to the right edge of the forefoot, and the insole body of the right foot is provided with a plurality of triangular notches 71 corresponding to the left edge of the forefoot, and the triangular notches are used to identify the left and right sides of the insole body. It is convenient for assembly line packaging of pairs of insoles. When packaging, first judge according to the shape...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com