Damping comfortable female fashion shoe and processing process thereof

A comfortable and feminine technology, applied in footwear, clothing, soles and other directions, it can solve the problems of poor anti-skid, perspiration and insect-proof effects, high manufacturing cost, low production efficiency, etc., and achieves fashionable appearance, good protection effect and quality. light effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

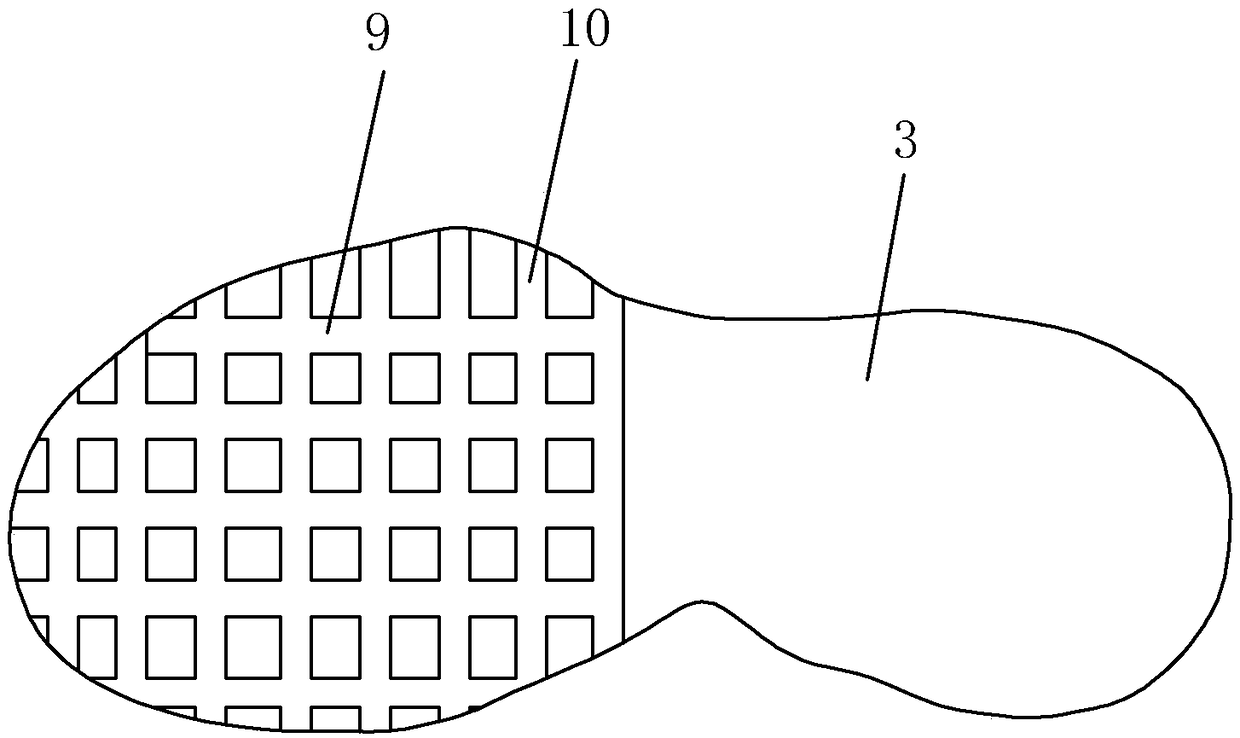

[0032] The present invention also provides a processing technology for the sole 3 of cushioning and comfortable lady's fashion shoes, comprising the following steps:

[0033] S1. Preparation of raw materials: 30 parts of natural rubber, 20 parts of viscous rubber, 40 parts of hard rubber, 33 parts of environmental protection rubber, 10 parts of coupling agent, 3 parts of filler, 3 parts of active agent, 2 parts of flame retardant, Accelerator 1 part;

[0034] S2. Weigh 30 parts of natural rubber, 20 parts of viscous rubber, 40 parts of hard rubber, and 33 parts of environmental protection rubber, place them in a melting furnace for stirring and heating, raise the temperature to 50° C., hold for 5 minutes, and extrude from the melting furnace;

[0035] S3. Put the molten raw materials extruded from the melting furnace in an internal mixer, and adjust the temperature to 80° C. for 2 minutes;

[0036] S4. After S3 is completed, add 2 parts of active agent to the internal mixer, ...

Embodiment 2

[0042] The present invention also provides a processing technology for the sole 3 of cushioning and comfortable lady's fashion shoes, comprising the following steps:

[0043] S1. Preparation of raw materials: 34 parts of natural rubber, 22 parts of viscous rubber, 46 parts of hard rubber, 37 parts of environmental protection rubber, 13 parts of coupling agent, 5 parts of filler, 4 parts of active agent, 2.5 parts of flame retardant, Accelerator 1.5 parts;

[0044]S2. Weigh 34 parts of natural rubber, 22 parts of viscous rubber, 46 parts of hard rubber, and 37 parts of environmental protection rubber, place them in a melting furnace for stirring and heating, raise the temperature to 60° C., keep it for 7 minutes, and extrude from the melting furnace;

[0045] S3. Put the molten raw materials extruded from the melting furnace in an internal mixer, and adjust the temperature to 85° C. for 2.5 minutes;

[0046] S4. After S3 is completed, add 3 parts of active agent to the interna...

Embodiment 3

[0052] The present invention also provides a processing technology for the sole 3 of cushioning and comfortable lady's fashion shoes, comprising the following steps:

[0053] S1. Preparation of raw materials: 36 parts of natural rubber, 24 parts of viscous rubber, 52 parts of hard rubber, 42 parts of environmental protection rubber, 15 parts of coupling agent, 7 parts of filler, 6 parts of active agent, 3 parts of flame retardant, Accelerator 2 parts;

[0054] S2. Weigh 36 parts of natural rubber, 24 parts of viscous rubber, 52 parts of hard rubber, and 42 parts of environmentally friendly rubber, place them in a melting furnace for stirring and heating, raise the temperature to 70° C., keep it for 10 minutes, and extrude from the melting furnace;

[0055] S3. Put the molten raw materials extruded from the melting furnace in an internal mixer, and adjust the temperature to 90° C. for 3 minutes;

[0056] S4. After S3 is completed, add 4 parts of active agent to the internal mi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com