Lacquer loudspeaker box manufacturing method

A production method and speaker technology, applied to devices, sensors, and electrical components that coat liquid on the surface, can solve problems that affect the health of users, the paint surface feels jerky, and the service life is short, so as to improve culture and aesthetics Taste, not easy to crack, good durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

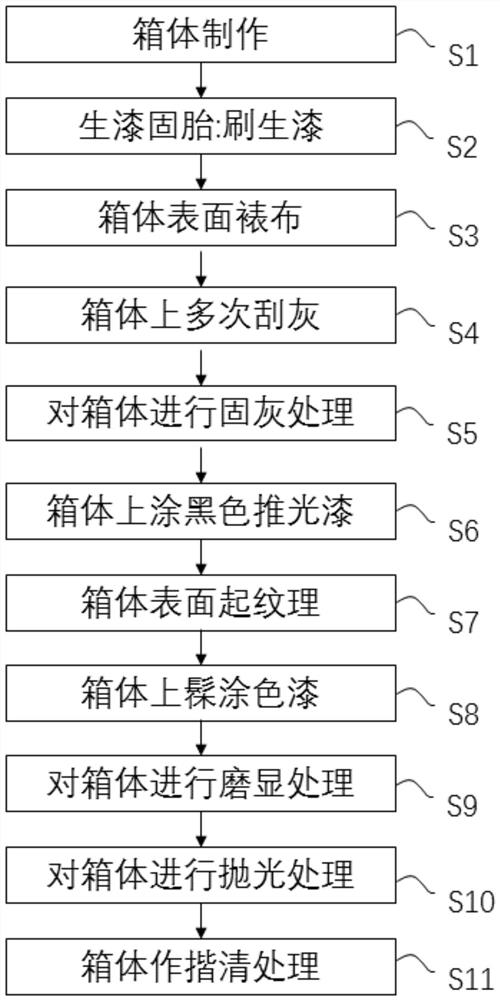

[0026] The present invention will be further described below in conjunction with the accompanying drawings.

[0027] see figure 1 , the present invention provides a kind of manufacture method of lacquer sound box, comprise raw lacquer, make according to the following steps:

[0028] S1. Cabinet production: speaker cabinet cutting; processing the long board and side board of the cabinet; processing the front panel of the speaker, that is, opening the speaker hole; cutting and opening the long board and side board after processing the tenon and tenon Groove processing; cabinet assembly; processing the back panel of the speaker cabinet; smoothing the uneven parts of the cabinet with 240-360 mesh sandpaper;

[0029] S2. Raw lacquer solidification: mix the bottom lacquer and thinner in a ratio of 1:1; use a brush to spread the mixed liquid all over the inside and outside of the box, let the paint eat into the wood, leave it for ten minutes after painting, and use a paper towel Or...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com