Pure polylactic acid fiber underwear shell fabric and manufacturing method thereof

A polylactic acid fiber, pure polylactic acid technology, applied in underwear, baby underwear, textiles and papermaking, etc., can solve the problems of polylactic acid fiber being hard to the touch, afraid of high temperature, etc., and achieve the effect of optimal expansion and stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

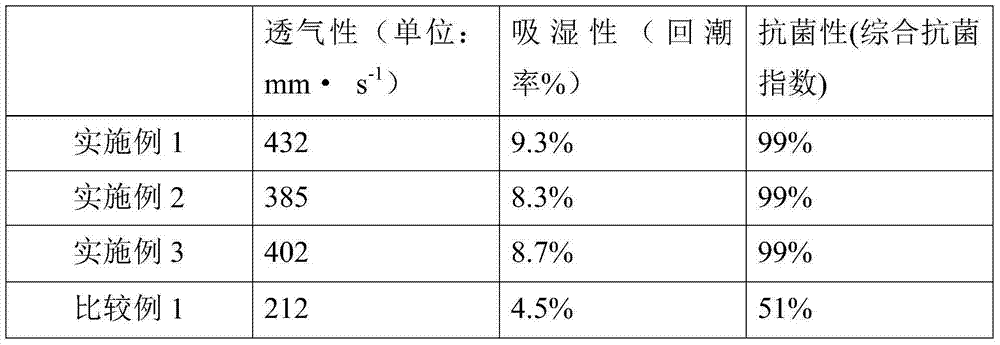

Examples

Embodiment 1

[0016] This embodiment provides a kind of women's underwear, including trouser body and crotch, described crotch is made up of inner layer and outer layer, and described inner layer and outer layer are respectively made of pure polylactic acid fiber underwear underwear fabric, The pure polylactic acid fiber underwear fabric is knitted or woven with 75D-150D polylactic acid fiber DTY filament and 30D-75D polylactic acid fiber FDY filament. The above-mentioned DTY polylactic acid fiber filament is formed by spinning, and its specific steps include POY and DTY. The process route of POY is: screw extruder → pre-filter → static mixer → metering pump → spinning assembly → Spinning → blowing and oiling → tunnel → POY winding yarn; among them: melt spinning temperature: 200-220°C; blowing conditions: wind speed 0.2-0.5m / s, wind temperature 25-30°C, relative humidity 60-75 %; the oiling rate is 0.70-1.20%; the spinning speed is 3500-5500m / min; the DTY production process route is: yarn ...

Embodiment 2

[0018] This embodiment provides a kind of women's underwear, including trouser body and crotch, described crotch is made up of inner layer and outer layer, and described inner layer and outer layer are respectively made of pure polylactic acid fiber underwear underwear fabric, The pure polylactic acid fiber underwear fabric is knitted by 30D-75D polylactic acid fiber DTY filaments on a double-sided machine.

Embodiment 3

[0020] This embodiment provides a kind of women's underwear, including trouser body and crotch, described crotch is made up of inner layer and outer layer, and described inner layer and outer layer are respectively made of pure polylactic acid fiber underwear underwear fabric, The pure polylactic acid fiber underwear fabric is woven with 50D-120D polylactic acid fiber DTY filament or 50D-90D polylactic acid fiber FDY filament.

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation | aaaaa | aaaaa |

| shrinkage | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com