A kind of sodium montmorillonite adsorption liquid and preparation method thereof

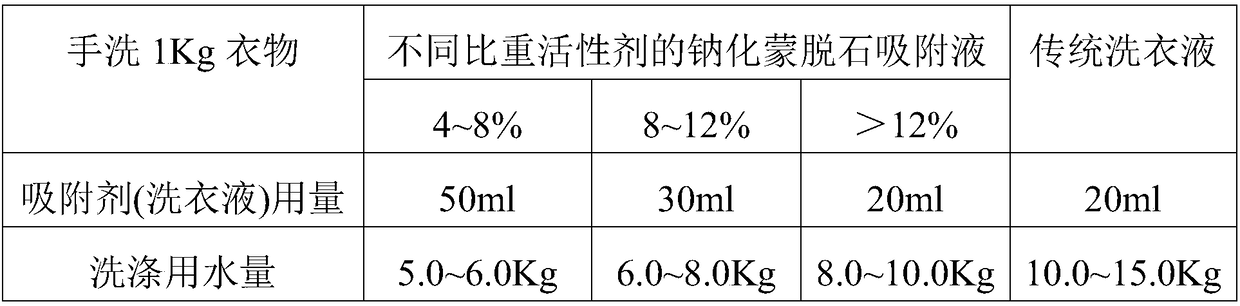

A technology of sodium montmorillonite and adsorption solution, which is applied in the direction of chemical instruments and methods, surface active non-soap compounds and cleaning compositions, soap detergent compositions, etc., to achieve increased decontamination ability, no softener, and mild performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Example 1: Preparation of sodium montmorillonite adsorption liquid

[0031] 1) Raw material preparation:

[0032] First, prepare 93.60kg of sodium montmorillonite microemulsion as raw material, 5.00kg of fatty acid methyl ester-α-sulfonate sodium and fatty alcohol polyoxyethylene ether sodium sulfate, and 1.40kg of alginic acid.

[0033] Among them, sodium fatty acid methyl ester-α-sulfonate is a common natural surfactant, alginic acid is a common natural thickener, and sodium fatty alcohol polyoxyethylene ether sulfate is a common non-natural surfactant. Of course, we can also use other natural surfactants to replace the sodium fatty acid methyl ester-α-sulfonate in this example, such as lecithin, sorbitan fatty acid ester, or sorbitan fatty acid ester derivatives. A mixture of any two or more of fatty acid methyl ester-α-sulfonate, lecithin, sorbitan fatty acid ester, and sorbitan fatty acid ester derivatives can also be used to replace the single fatty acid methyl e...

Embodiment 2

[0037] Embodiment 2: the preparation of sodium montmorillonite adsorption liquid

[0038] 1) Raw material preparation:

[0039] First, prepare 91.42Kg of sodium montmorillonite microemulsion as raw material, 6.80kg of lecithin (which is a natural surfactant) and sodium alkyl benzene sulfonate (which is a non-natural surfactant), a total of 6.80kg of sodium alginate (It is a natural thickener) 1.78 kg.

[0040] 2) Mix

[0041] In a high-speed disperser with a 200L container, add the prepared sodium montmorillonite microemulsion, slowly add the prepared surfactant under stirring conditions, and then add the prepared surfactant after it is completely dispersed, and then add it to 6.5% dissolved in water. The mass concentration of the natural thickener is adjusted to a suitable viscosity, the dispersion is stopped, and the product can be filled after the foam is eliminated, thereby obtaining the packaged product of the sodium montmorillonite adsorption liquid of the present inve...

Embodiment 3

[0042] Embodiment 3: the preparation of sodium montmorillonite adsorption liquid

[0043] 1) Raw material preparation:

[0044] First, prepare 90.35Kg of sodium montmorillonite microemulsion as raw material, sorbitan fatty acid ester (which is a natural surfactant) and sodium alkyl benzene sulfonate (which is a non-natural surfactant) in total of 9.00 kg, pectin (which is a natural thickening agent) 0.65 kg.

[0045] 2) Mix

[0046] In a high-speed disperser with a 200L container, add the prepared sodium montmorillonite microemulsion, slowly add the prepared surfactant under stirring conditions, and then add the prepared surfactant after it is completely dispersed to make up 10% The natural thickener of mass concentration, adjust the viscosity to appropriate (the suitable viscosity mentioned here is usually 2000-3000mpa.s), stop dispersing, stand still and wait for the foam to be eliminated before filling, thereby obtaining the sodium montmorillonite of the present invention...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com