A kind of bamboo fragrance cigarette paper and preparation method thereof

A technology for cigarette paper and bamboo fragrance, which is applied in the field of bamboo fragrance cigarette paper and its preparation, can solve the problems of reduction, heavy wood smell and low smoking quality, and achieves the advantages of reduced cost, good air permeability and improved smoking comfort. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

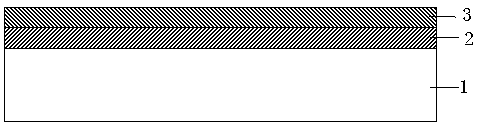

[0038] A kind of bamboo fragrance cigarette paper, comprises the natural bamboo fragrance fragrance layer 3 that is arranged in sequence, printing pattern layer 2 and bamboo fiber base paper layer 1, as figure 1 As shown; the bamboo fiber base paper layer is made of mixed pulp, and the mixed pulp is composed of the following substances in terms of mass percentage: 50% bamboo pulp, 20% hemp pulp, and 30% wood pulp.

[0039] In this embodiment, the natural bamboo fragrance layer is a coating of natural fragrance, and the natural fragrance is freshly squeezed bamboo juice.

[0040] The preparation method of the bamboo incense cigarette paper of the present embodiment is as follows:

[0041] A. Preparation of bamboo pulp

[0042] A1. Air-dry the Nenci bamboo, retting in water for 20 days in the cellar, after degreening, pick it up, dry it, cut it, smash it, put it in the retting pool, soak it with lime for 10 days, and heat it to 80-95°C , steamed for 24 hours;

[0043] A2. The...

Embodiment 2

[0049] A kind of bamboo fragrance cigarette paper, comprises the natural bamboo fragrance fragrance layer 3 that is arranged in sequence, printing pattern layer 2 and bamboo fiber base paper layer 1, as figure 1As shown; the bamboo fiber base paper layer is made of mixed pulp, and the mixed pulp is composed of the following substances in terms of mass percentage: 30% bamboo pulp, 20% hemp pulp, and 50% wood pulp.

[0050] In this embodiment, the natural bamboo fragrance layer is a natural fragrance coating, and the natural fragrance is bamboo leek.

[0051] The preparation method of the bamboo incense cigarette paper of the present embodiment is as follows:

[0052] A. Preparation of bamboo pulp

[0053] A1. Naturally air-dry the Nenci bamboo, retting in water for 35 days in the cellar, after removing the green, pick it up, dry it, cut it, smash it, put it in the retting pool, soak it with lime for 15 days, and heat it to 80-90 °C, cook for 24 hours;

[0054] A2. beating th...

Embodiment 3

[0060] A kind of bamboo fragrance cigarette paper, comprises the natural bamboo fragrance fragrance layer 3 that is arranged in sequence, printing pattern layer 2 and bamboo fiber base paper layer 1, as figure 1 As shown; the bamboo fiber base paper layer is made of mixed pulp, and the mixed pulp is composed of the following substances in terms of mass percentage: 90% bamboo pulp, 5% hemp pulp, and 5% wood pulp.

[0061] In this embodiment, the natural bamboo fragrance layer is a coating of natural fragrance, and the natural fragrance is the extract of Cizhu flower.

[0062] The preparation method of the bamboo incense cigarette paper of the present embodiment is as follows:

[0063] A. Preparation of bamboo pulp

[0064] A1. Air-dry Nenci bamboo, retting in water for 40 days in the cellar, after degreening, pick up and dry, cut and smash, put in the retting pool, soak with lime for 15 days, then heat to 80-90°C , cook for 30 hours;

[0065] A2. the bamboo material after co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com