Roller printing machine

A technology of cylinder printing machine and printing cylinder, which is used in printing presses, rotary printing presses, gravure rotary printing presses, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

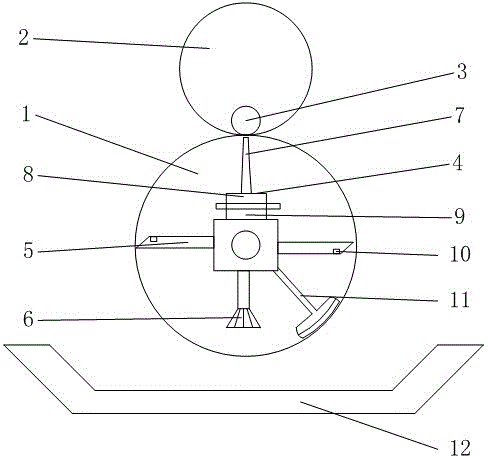

[0015] Below in conjunction with accompanying drawing and embodiment the present invention is described in further detail: as figure 1 As shown, a roller printing machine includes a printing cylinder 1 and a pressure cylinder 2, and engraves the pattern to be printed on the printing cylinder 1, wherein a heating roller 3 is arranged in the pressure cylinder 2, and the heating roller 3 can Continue to provide stable heat to heat the pressure cylinder, the heating roller 3 is inscribed on the pressure cylinder 2, and rolls in the same direction as the pressure cylinder 2; the printing cylinder 1 is provided with a material spraying device 4 , material picking knife 5 and blower fan 6; Described material spraying device 4 comprises material spraying port 7, ultrasonic dispersing device 8 and pressurizing device 9, and the ink material is broken up by ultrasonic dispersing device 8, passes through pressurizing device 9 It is ejected from the spray port, passes through the hol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com