Steel rail distance regulator

A technology of adjusters and rails, applied in the directions of rails, measuring instruments, laying rails, etc., can solve the problems of inconvenience of carrying, increased weight of the whole machine, long length, etc., and achieves the effect of simple operation, compact structure and guaranteed accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

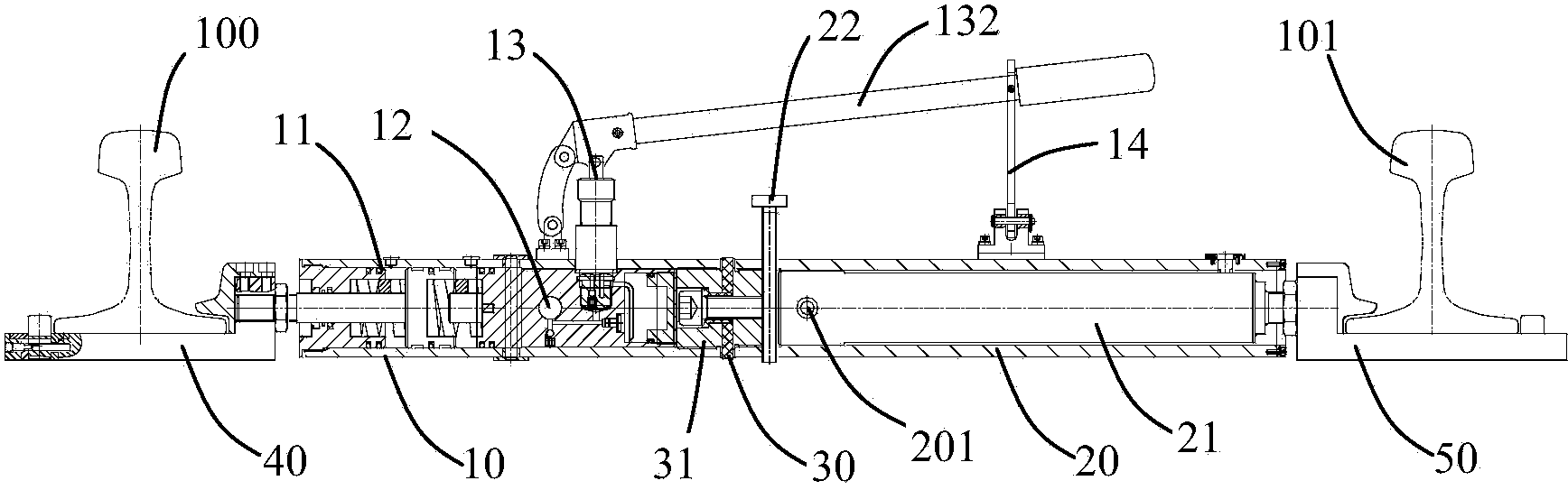

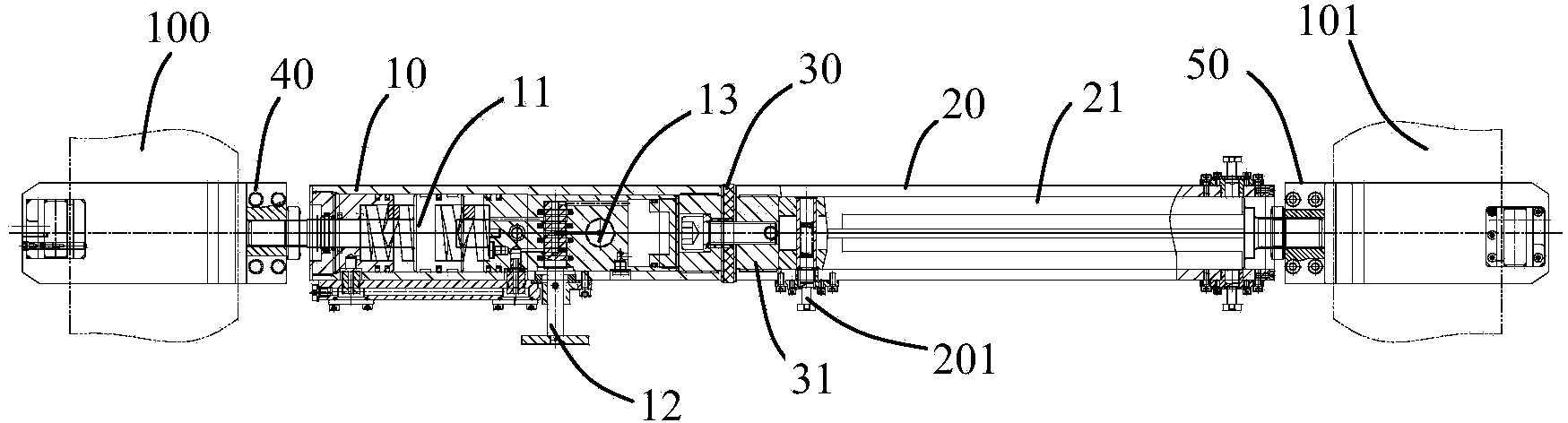

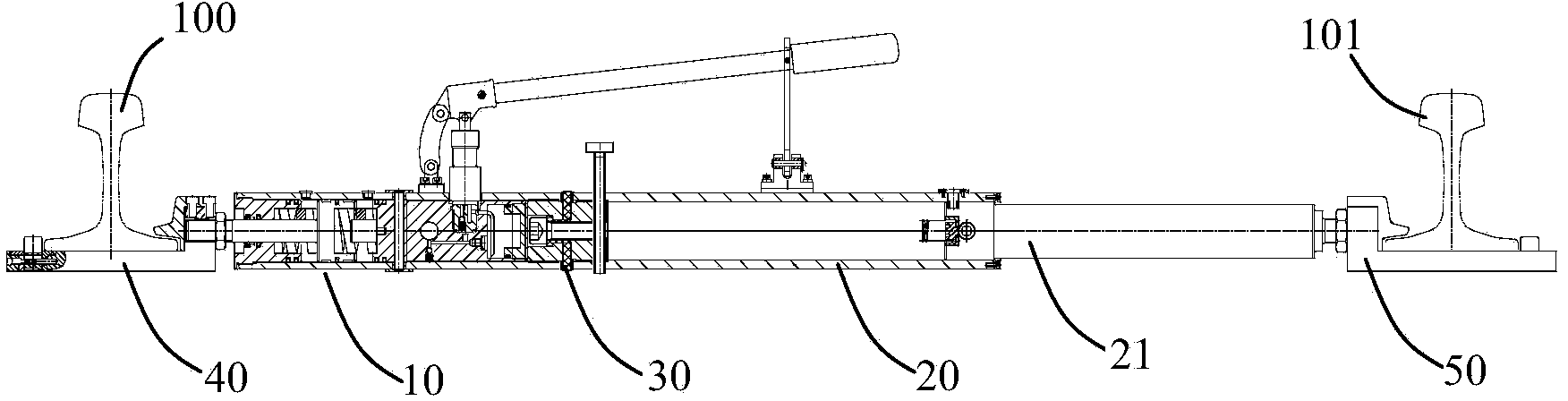

[0029] Specific embodiments of the present invention will be described in detail below with reference to the accompanying drawings. These descriptions are descriptive and exemplary only.

[0030] see Figure 1~6 , the rail gauge adjuster of the present invention comprises a left cylinder 10, a right cylinder 20, and a left clamp 40 and a right clamp 50 for clamping the rails 100, 101 on both sides, the left cylinder 10 and An insulator 30 is provided between the right cylinders 20, and the left cylinder 10 and the right cylinder 20 are fixedly connected by a threaded connector 31; the left cylinder 10 is provided with a hydraulic cylinder 11, a reversing valve 12 and Manual pump 13, the piston rod 111 of the hydraulic cylinder 11 is fixedly connected with the left clamping member 40, the right cylinder 20 is provided with a sliding pull rod 21 that can move in the right cylinder 20 and can be locked and fixed, The end of the sliding rod 21 is fixedly connected with the right...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com