Nonuniform correction method for thermal infrared imager

An infrared thermal imager, non-uniformity correction technology, applied in the field of infrared thermal imager, can solve the problem that the lens non-uniformity cannot be eliminated

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

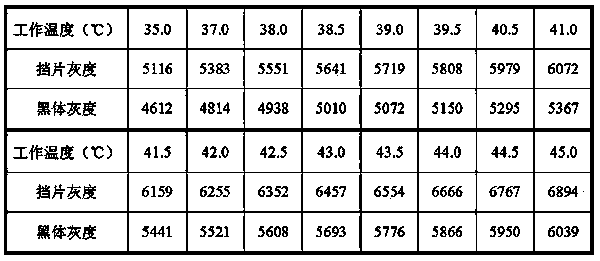

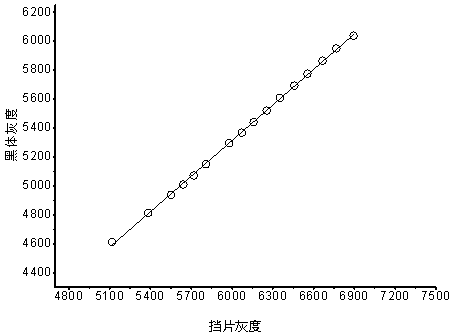

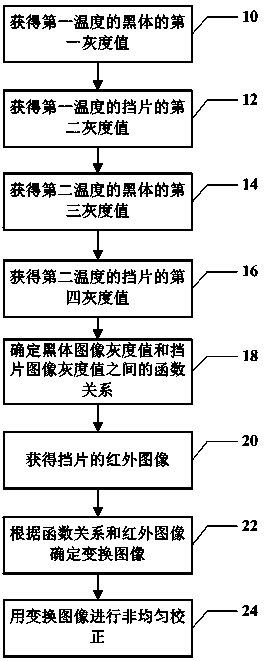

[0016] The principle and specific steps of the method for correcting the non-uniformity of the infrared thermal imager according to the embodiment of the present invention will be described in detail below with reference to the accompanying drawings.

[0017] An infrared thermal imaging camera usually includes an infrared focal plane array detector (hereinafter referred to as "detector") and a lens, and a barrier is usually set between the lens and the detector. The baffle is movable and can be in the blocking position (at this time the baffle is located on the optical path from the lens to the detector, that is, blocking infrared radiation from the lens to the detector) and the out of position (at this time the baffle is not located on the optical path from the lens to the detector) The optical path to the detector, allowing the infrared radiation to travel (for example, by rotating it) between the lens and the detector). The baffle is used for non-uniform correction of the i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com