Measurement device for thin film pressure sensor

A thin-film pressure and measuring device technology, which is applied in the direction of measuring devices, calibration/testing of force/torque/power measuring instruments, and measurement of fluid pressure. Corresponding to measurement and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention is described in detail below in conjunction with embodiment and accompanying drawing thereof, but the present invention is not limited by embodiment:

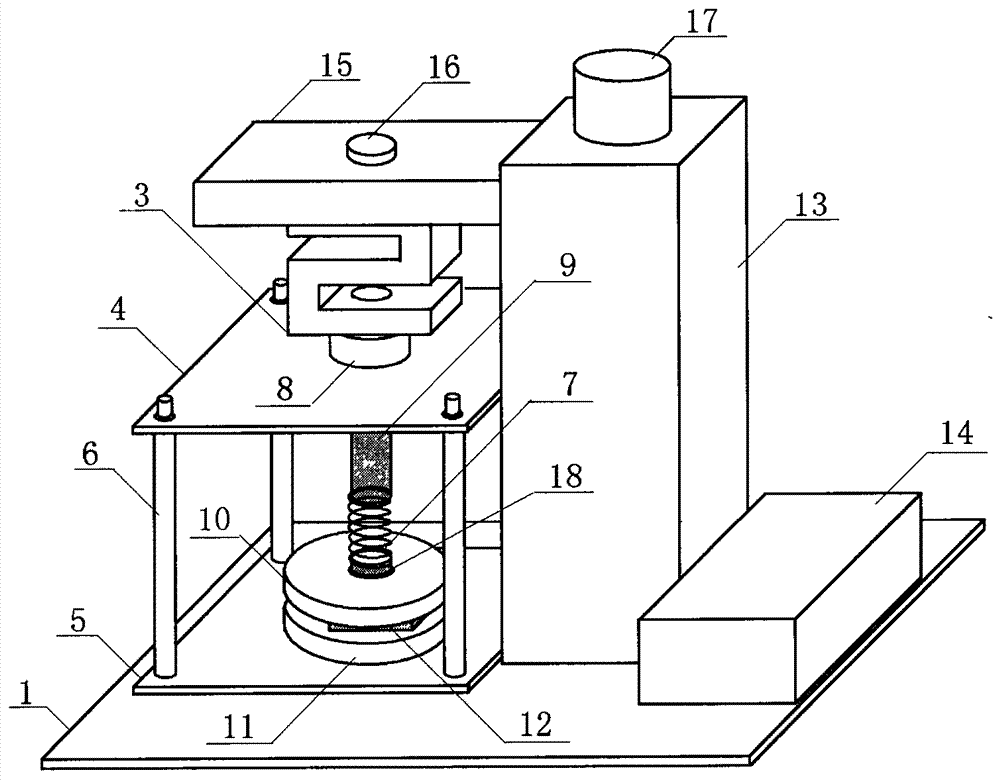

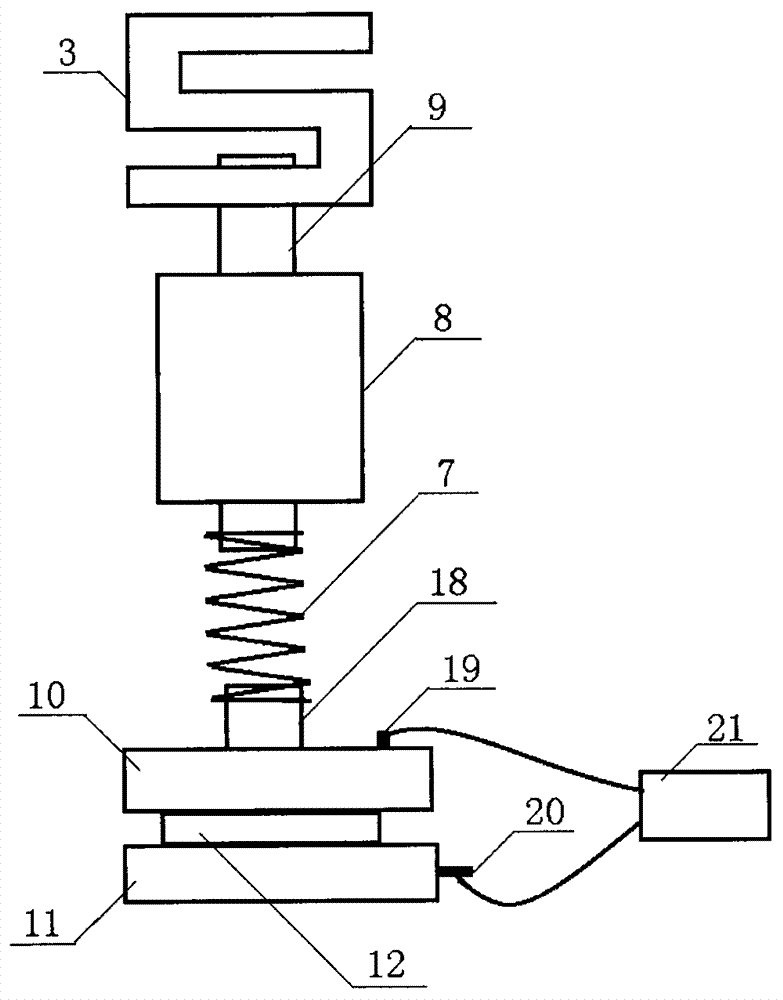

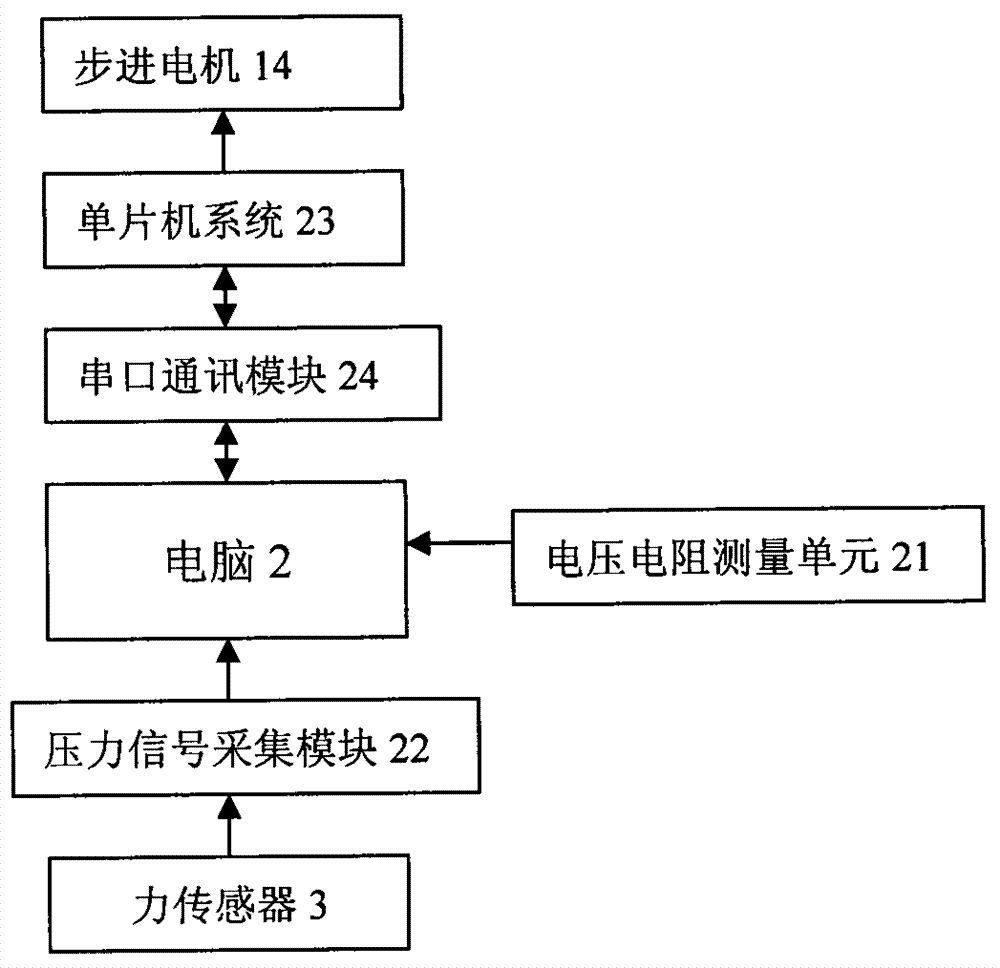

[0016] The measuring device of a kind of membrane pressure sensor of the present invention (referring to Figure 1-2 ), the measurement device of the thin film pressure sensor includes a measurement mechanism and a control and signal acquisition part. The measuring mechanism includes a bottom plate 1, a screw rod 17, a beam bracket 13, a stepping motor 14, a beam 15, a force sensor 3, a linear bearing 8, a shaft 9, a spring 7, an upper electrode 10, a lower electrode 11, an upper support plate 4, a lower Support plate 5, support column 6 etc., described measuring mechanism is characterized in that described force sensor 3 is fixed on the crossbeam 15 by screw 16, and described crossbeam 15 is sleeved on the screw mandrel 17, and stepper motor 14 can drive wire The rod 17 rotates and drives the beam...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com