Device and method for testing whether camera module is qualified or not

A camera module and a qualified technology, applied in the field of devices for testing whether the camera module is qualified, can solve the problems affecting the test efficiency of the camera module, the adjustment time, etc., to improve the test efficiency, shorten the time, and have a high degree of programming Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

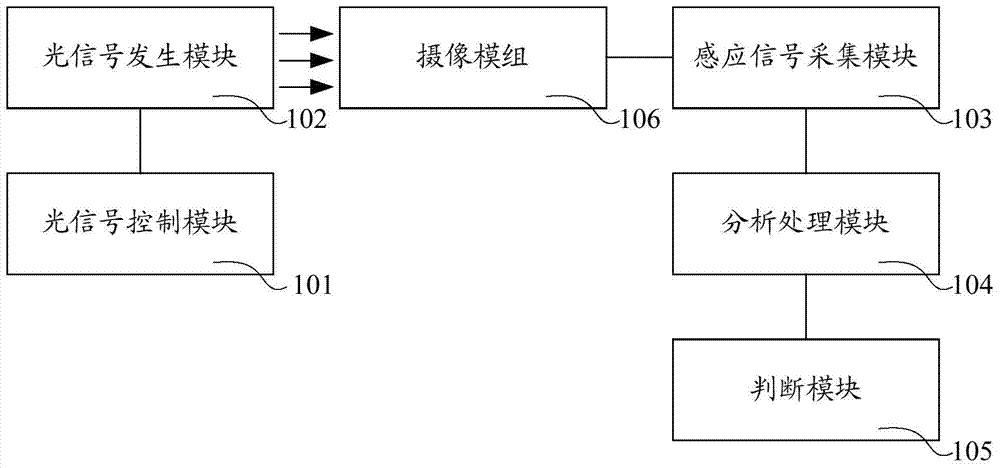

[0027] This embodiment provides a device for testing whether the camera module is qualified, such as figure 1 As shown, the device includes: an optical signal control module 101, an optical signal generation module 102, an induction signal acquisition module 103, an analysis and processing module 104, and a judgment module 105;

[0028] The optical signal control module 101 is connected to the optical signal generating module 102, and controls the optical signal generating module 102 to provide an optical signal for the photosensitive chip 301 of the camera module 106;

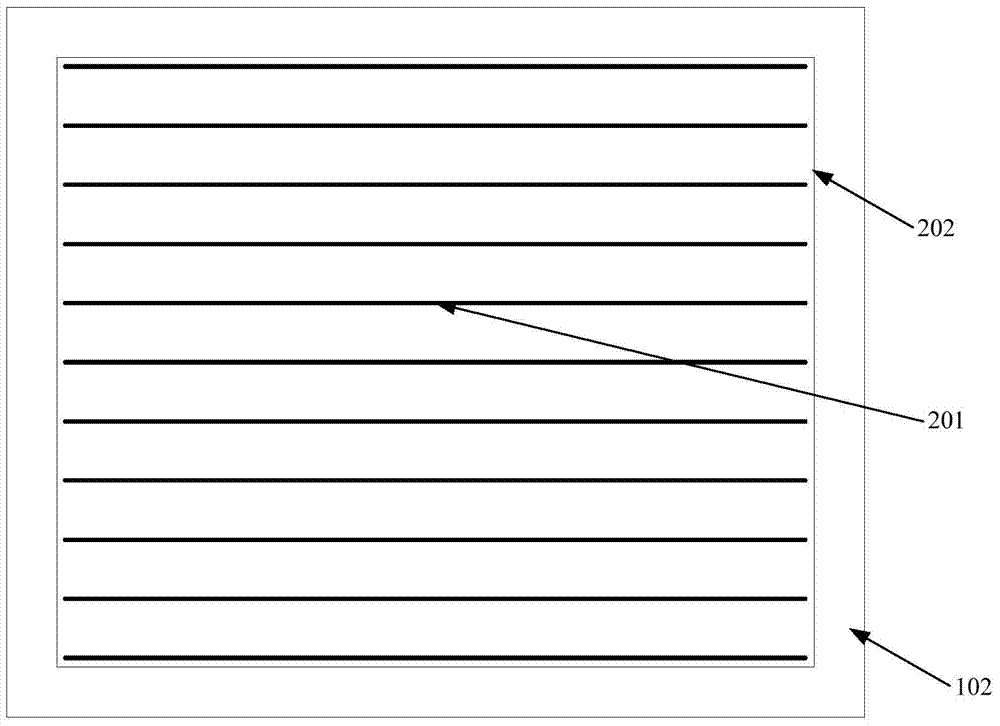

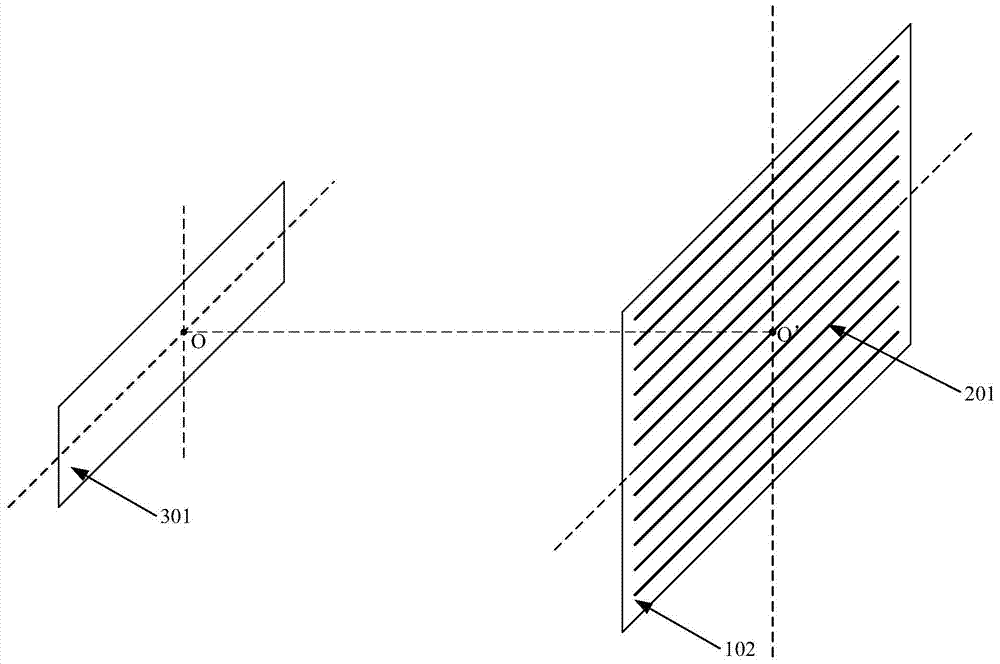

[0029] Such as figure 2 As shown, the optical signal generating module 102 includes a plurality of light-emitting units 201 arranged in a grid shape. The plurality of light-emitting units 201 are all bar-shaped structures, arranged parallel to each other, evenly spaced, and flush at the ends. On the plane, a rectangular light-emitting area 202 is formed, such as image 3As shown, the light-emitting region 2...

Embodiment 2

[0044] This embodiment provides a method for testing whether the camera module is qualified, the method is used in the device described in Embodiment 1, and the method includes:

[0045] Step S71: Place a camera module on one side of the optical signal generating module so that the light-emitting area of the optical signal generating module is parallel to the photosensitive chip of the camera module and the centers of the two are on the same straight line, and the The plurality of light-emitting units of the optical signal generating module are parallel to the long side of the photosensitive chip, the optical signal generating module is connected to the optical signal control module, and the camera module is connected to the sensing signal collection The modules are connected;

[0046] Step S72: using the optical signal control module to control the optical signal generating module to respectively turn on each light emitting unit of the optical signal generating module once,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com