Material conveying device for chip mounter

A technology of feeding device and placement machine, applied in the direction of electrical components, electrical components, etc., can solve the problems of material shape limitation, large space occupation area, long strip materials cannot be conveyed, etc., to achieve the effect of reasonable design and space saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with the accompanying drawings.

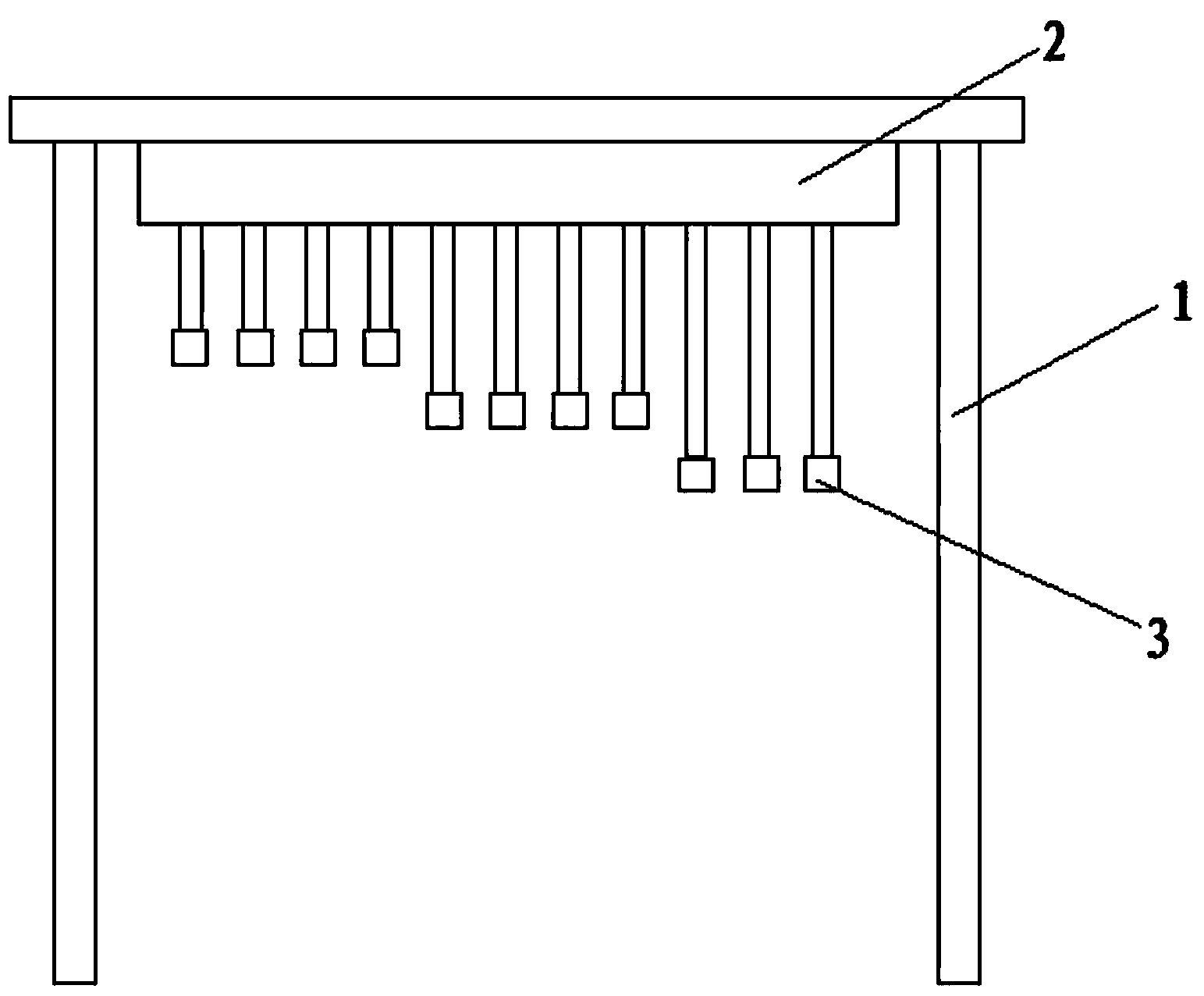

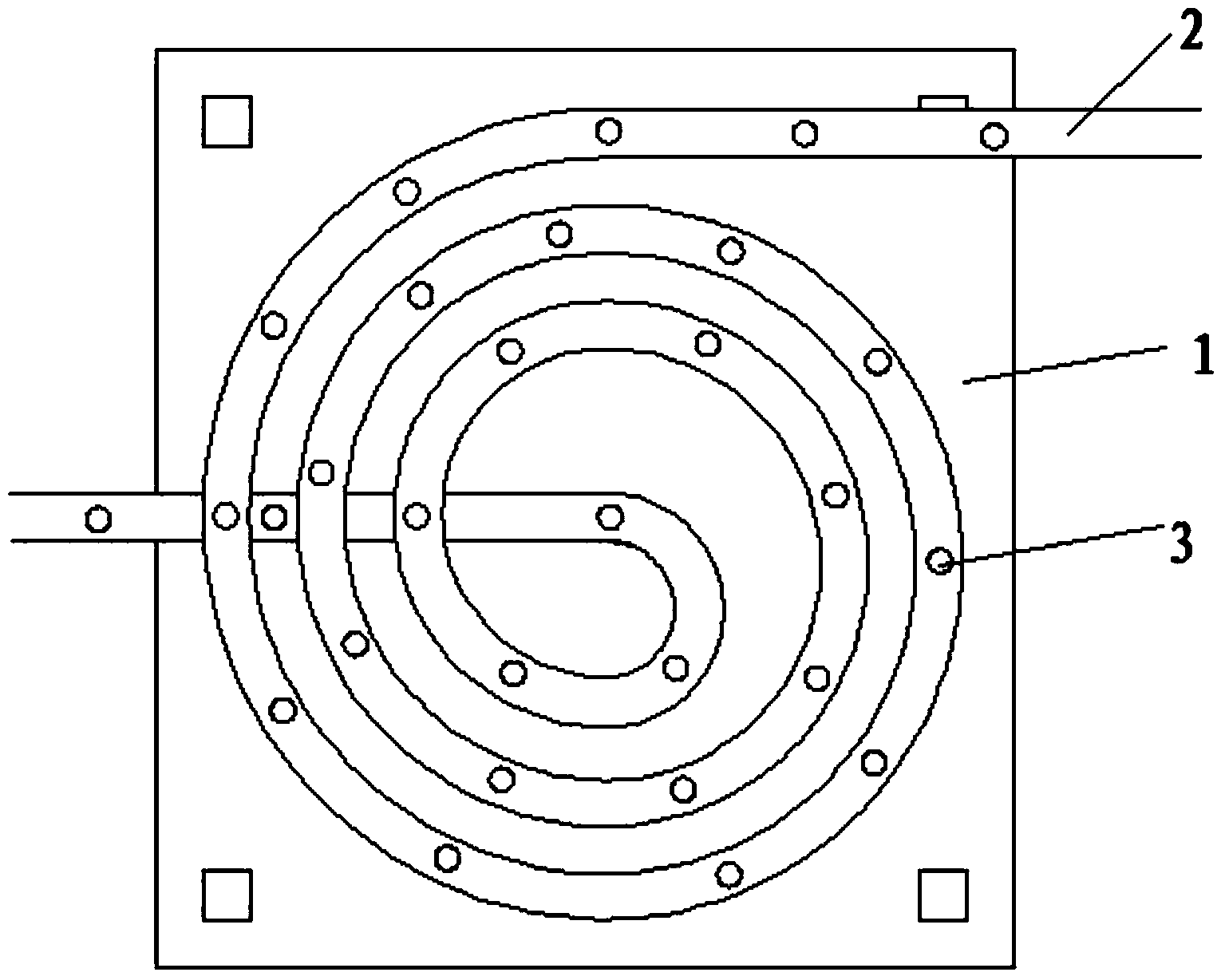

[0014] Such as Figure 1-2 As shown, a feeding device of a placement machine includes a feeding bracket 1 and a feeding tube belt 2, and is characterized in that: the feeding bracket 1 includes a vertical rod and a cross bar, and one end of the vertical rod is fixedly connected to the ground, and the vertical rod The other end is fixedly connected with the cross bar; the feeding pipe belt 2 spirals into at least 3 layers of rings, and the feeding pipe belt 2 is provided with a plurality of grasping hands 3, and the feeding pipe belt 2 and the grasping material The corresponding surface of the hand 3 is fixedly connected with the lower surface of the cross bar.

[0015] The gripping hand 3 includes a gripper for grabbing materials, and a connecting rod connecting the gripper and the feeding pipe belt 2 .

[0016] The connecting rods support length adjustment, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com