Punching die capable of realizing continuous punching

A technology for stamping dies and punches, applied in the field of stamping dies for sustainable stamping, can solve problems such as difficulty in guaranteeing stamping accuracy, and achieve the effects of improving stamping accuracy, preventing misfeeding of materials, and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

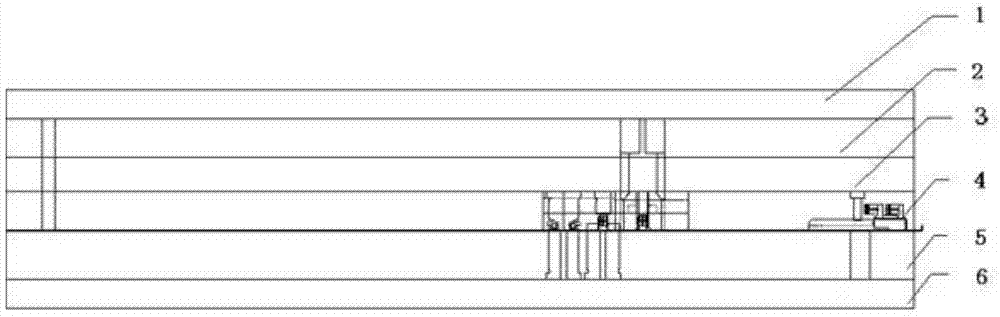

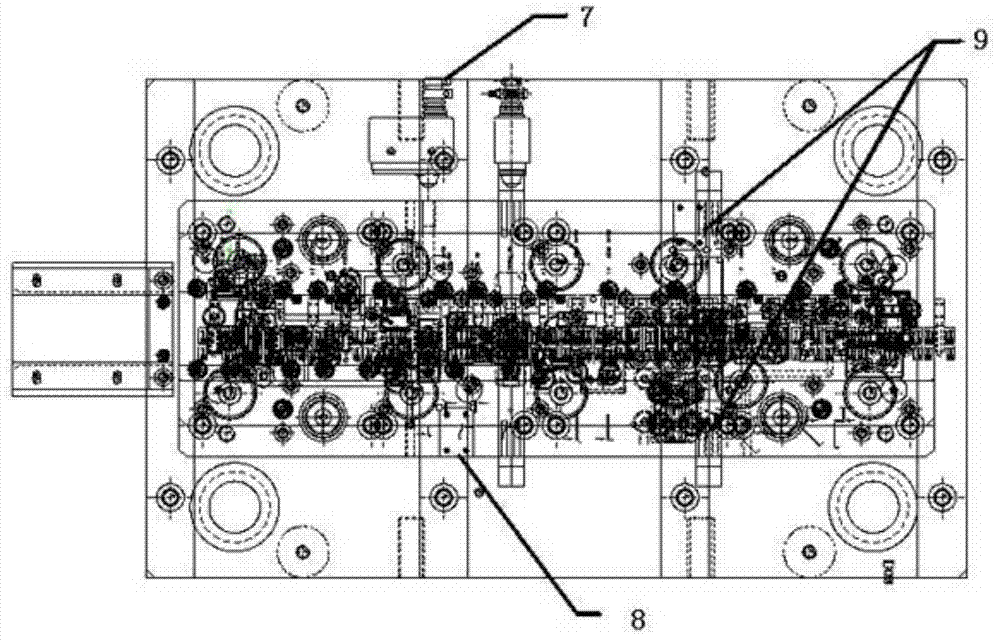

[0014] like figure 1 , figure 2 As shown, a stamping die for sustainable stamping provided by the present invention includes an upper backing plate 1 , a punch fixing plate 2 , a stripping plate 3 , a blanking plate 4 , a lower backing plate 5 and a lower mold base 6 . There are misreading detection pins 7 and bottom dead center sensors 8 on the side of the feed port to prevent misfeeding of materials and damage to processed parts; two-way adjustment rods 9 are installed on both sides of the mold to adjust the size changes during stamping Realize dismantling-free adjustment, greatly improving efficiency and stamping precision.

[0015] Those of ordinary skill in the art should recognize that the above embodiments are only used to illustrate the present invention, rather than as a limitation to the present invention, as long as with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com