Multi-cone premix burners for gas turbines

A technology of gas turbines and burners, which is applied in the direction of gas turbine devices, gas fuel burners, burners, etc., and can solve problems such as non-formation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] In known AEV burner design concepts a transition piece is required in order to adapt the sickle-shaped cross-section at the swirler outlet to the cylindrical cross-section of the mixing tube (see eg document WO2009 / 019113A2 cited above). This transition piece requires careful aerodynamic layout in order to avoid flow separation and resulting flashback.

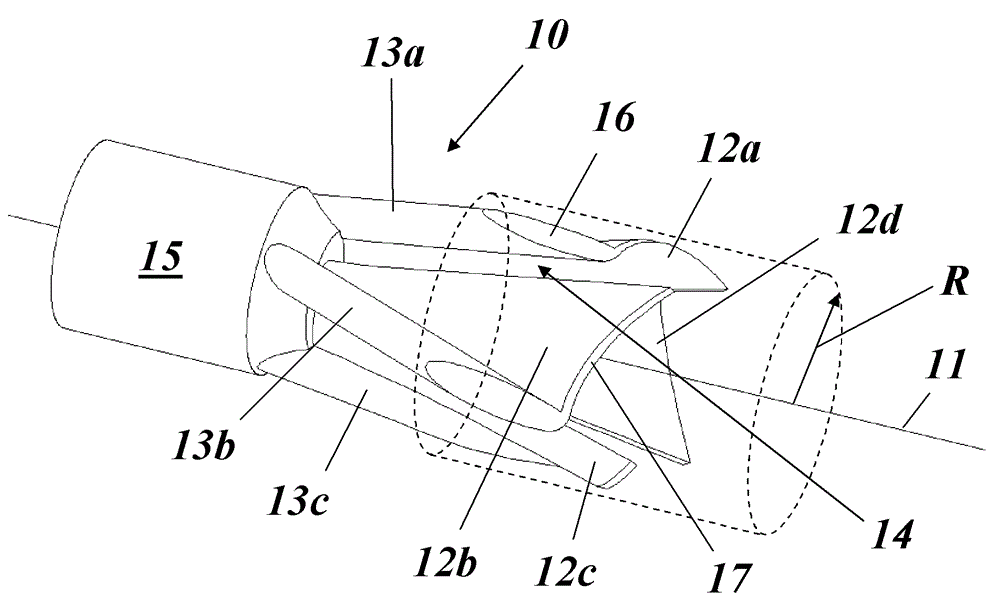

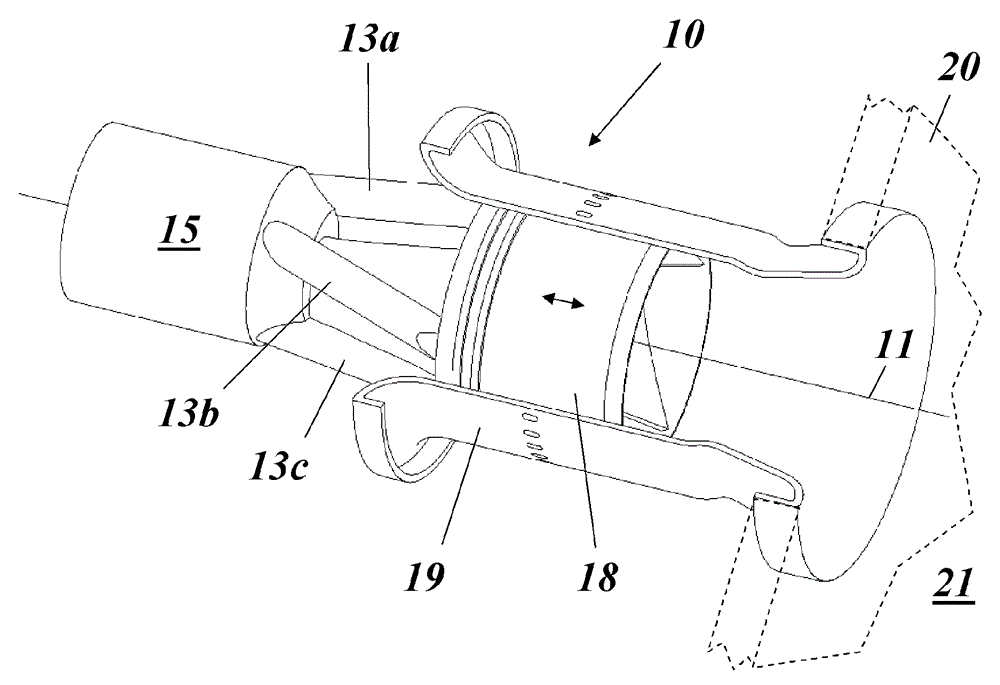

[0032] The present invention avoids the need for a transition piece. The downstream end of the conical casing is formed such that the casing is cut in the cylindrical shape of the burner ring which is an integral part of the withdrawable burner. figure 1 with figure 2 The illustrated embodiment shows the basic principle of this solution.

[0033] figure 1 The premix burner 10 extends along a central burner axis 11 . The burner comprises four identical casings 12a-d which are part of a virtual cone open in the downstream direction (extending from left to right in the figure). The casings are displaced from their in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com