A detection method for the installation position of the core in sand casting

An installation location, sand casting technology, applied in casting molding equipment, cores, molds, etc., can solve the problems of lack of detection devices and methods, increased production costs, under-casting size of castings, etc., to improve the pass rate, internal The effect of improving the metallurgical quality and improving the dimensional stability of castings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

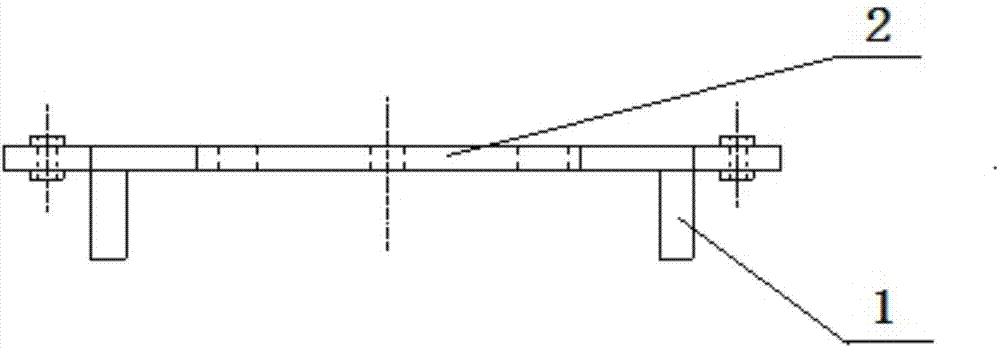

[0024] Such as figure 1 , Figure 5 As shown, a method for detecting the installation position of the core in sand casting mainly includes the following steps:

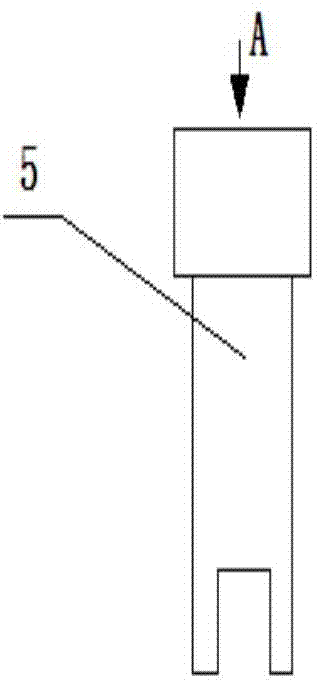

[0025] A. First make a detection device according to the correct position of the main body core (9) in the lower sand box (8). The detection device is composed of a column (1) and a horizontal plate (2). The horizontal plate (2) is arranged on two columns ( 1) On the top, the distance between the two columns (1) is equal to the width of the lower sand box (8), and a detection part is provided on the horizontal plate (2). The top view orthographic drawing of the correct position in (8) is processed and produced, the height of the column (1) is equal to the top of the main body core (9) and the lower sand box when the main body core (9) is in the correct position in the lower sand box (8) (8) The distance between the upper planes of the side plates, the detection device is provided with a positioning and fixing part c...

Embodiment 2

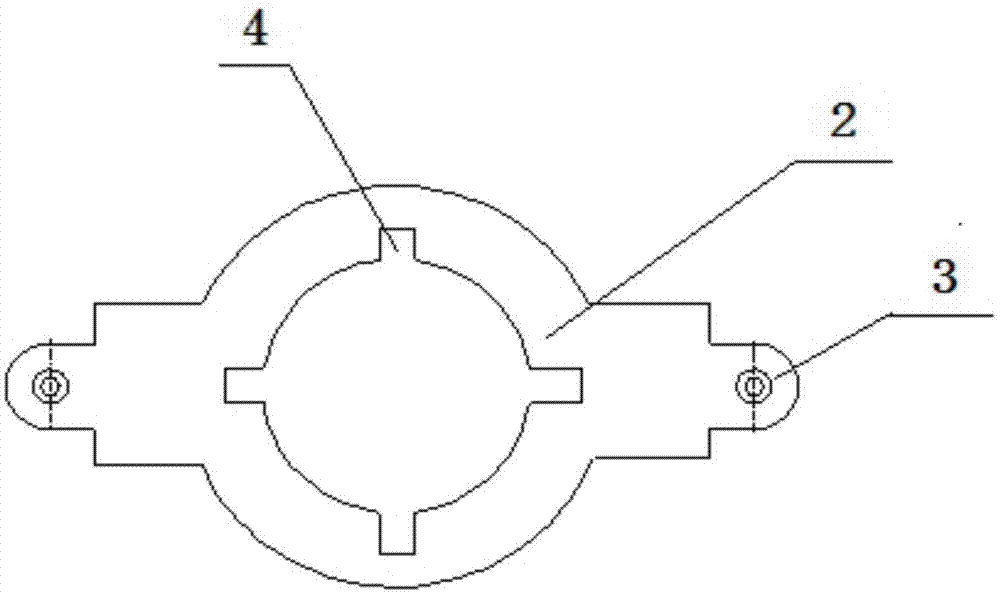

[0033] Such as figure 1 , 2 , 3, 4, and 5, a method for detecting the installation position of the core in the sand casting of casing castings mainly includes the following steps:

[0034] A. First make a detection device according to the correct position of the main body core (9) in the lower sand box (8). The detection device is composed of a column (1) and a horizontal plate (2). The horizontal plate (2) is arranged on two columns ( 1) On the top, the distance between the two columns (1) is equal to the width of the lower sand box (8), and a detection part is provided on the horizontal plate (2). The top view orthographic drawing of the correct position in (8) is processed and produced, the height of the column (1) is equal to the top of the main body core (9) and the lower sand box when the main body core (9) is in the correct position in the lower sand box (8) (8) The distance between the upper planes of the side plates, the detection device is provided with a positioni...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com