A Design Method of Double Oriented Hollow Blade Casting System

A pouring system and hollow blade technology, applied in casting molding equipment, metal processing equipment, casting mold composition, etc., to achieve the effect of improving casting qualification rate, increasing the number of seeding, and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

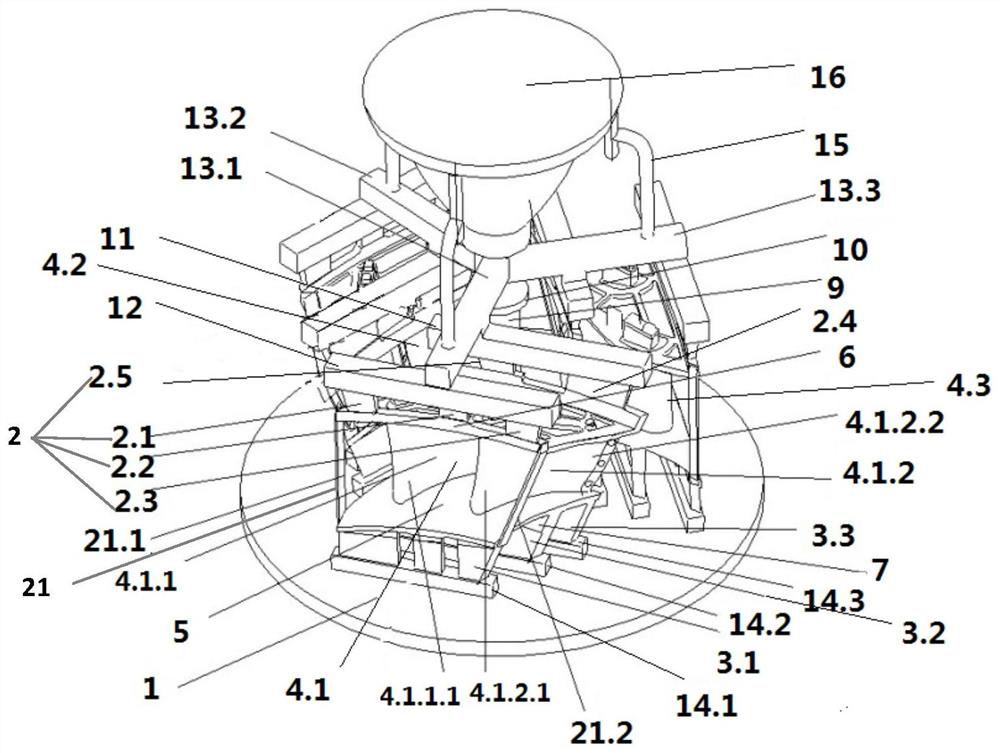

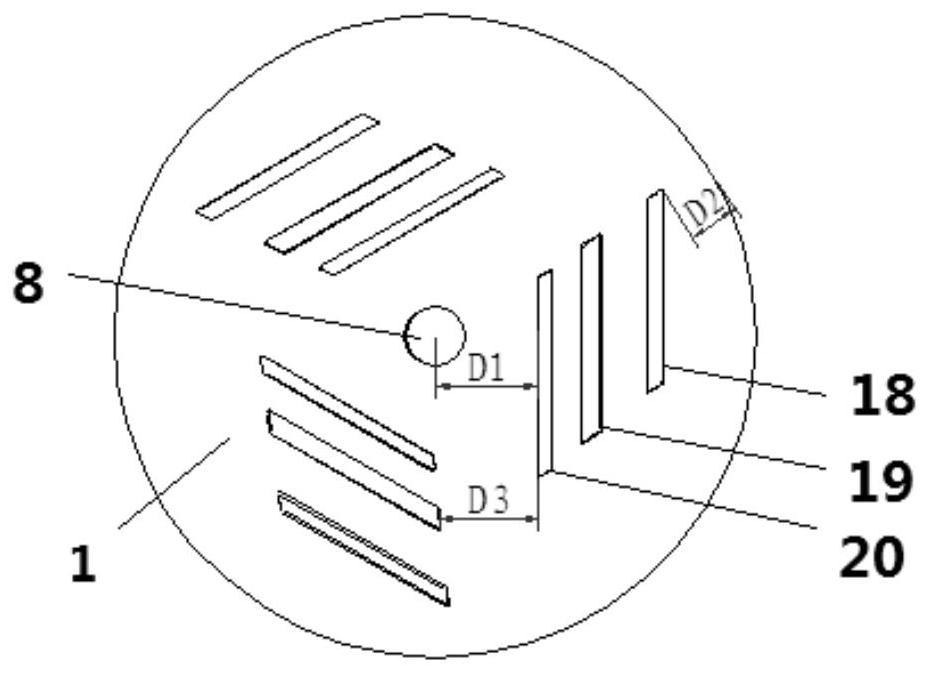

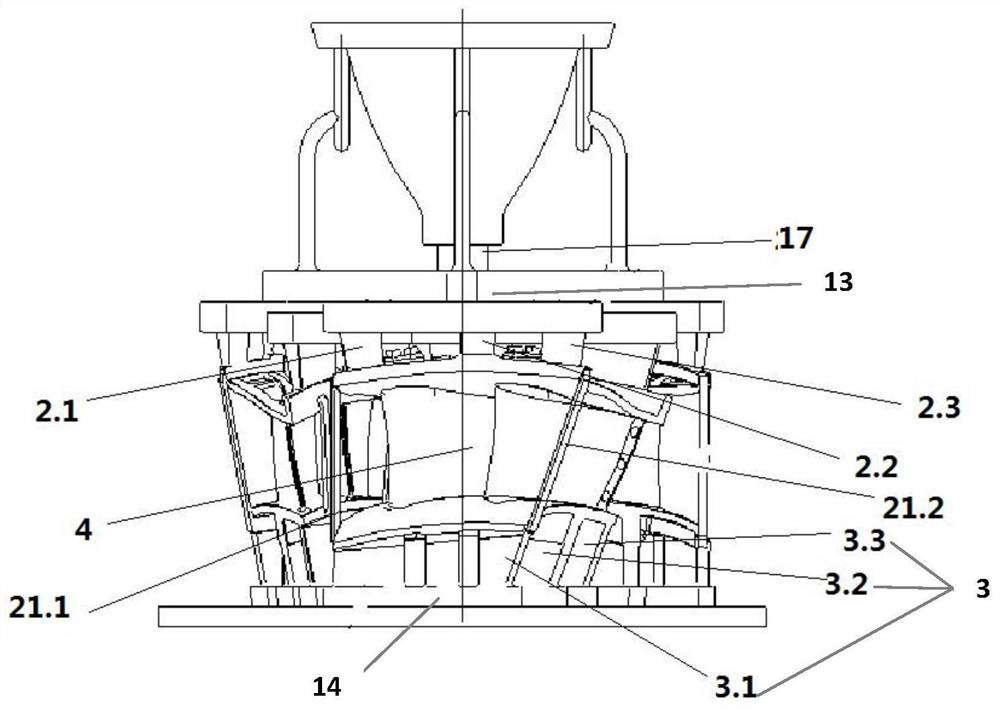

[0035] In order to understand the present invention more clearly, the present invention will be described in further detail in connection with the accompanying drawings.

[0036] Below Figure 1-3 A design method of a duplex hollow blade casting system provided in accordance with an embodiment of the present invention is described.

[0037]A design method of a two-way directional hollow blade casting system includes the following steps.

[0038] 1) combination of casting systems;

[0039] 2) Made of the wax mold module;

[0040] 3) Put the housing into the three chamber vacuum furnace to complete the cast, preferably the example casting is 1480 ° C, the pulley speed is 4 mm / min.

[0041] like Figure 1 to 3 As shown, a two-setup of the blade is preferred as an example, and a set of blades of the blade is the same, and the combination of the casting system of each blade is the same, wherein the combination of the casting system is specifically adopted:

[0042] Step 1: Establish th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com