A method for automatic assembly of electric meter hook

An automatic assembly and electric meter technology, which is applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve the technical process and method of the automatic assembly device for the electric meter hook, the electric meter cannot be used normally, and the installation efficiency is low. Issues such as assembly High efficiency, easy operation and high level of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

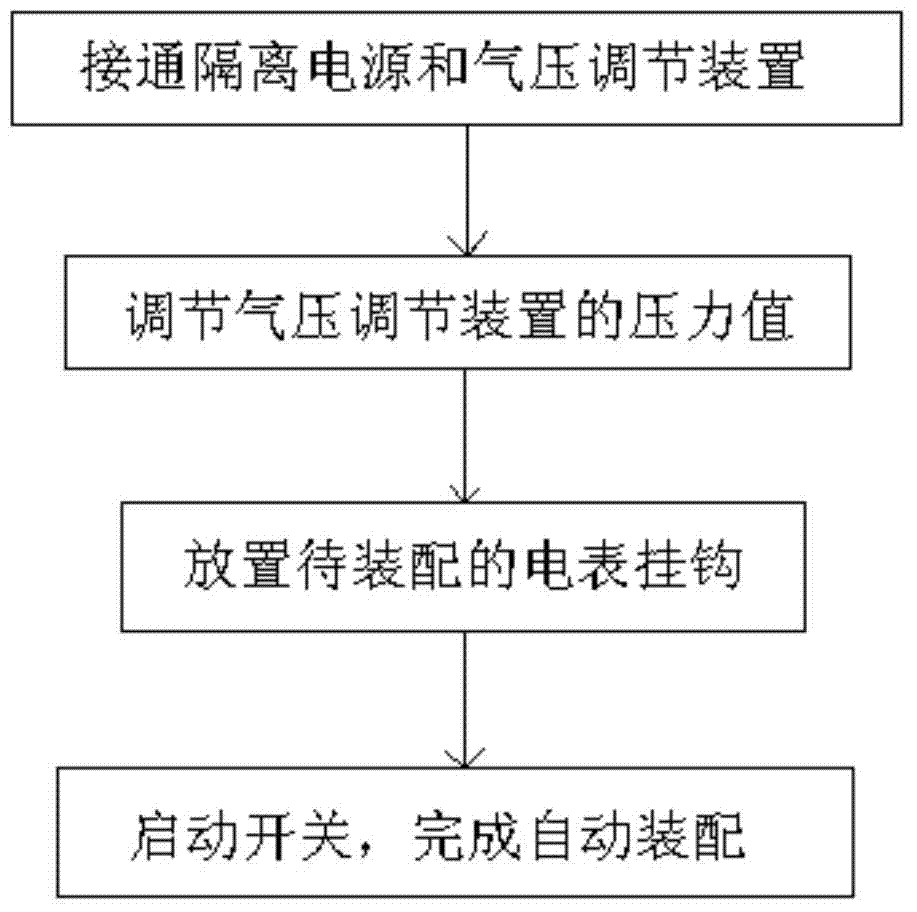

[0015] The process steps of the automatic assembly method for the electric meter hook involved in this embodiment are:

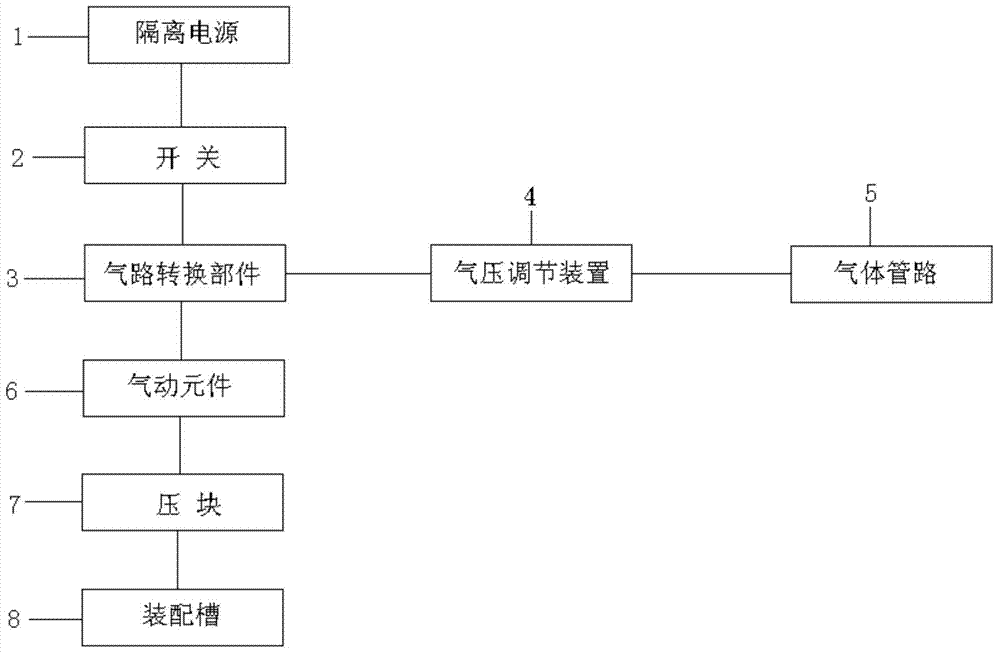

[0016] (1) Organize and install the electric meter hook automatic assembly device according to the structural design requirements first, then connect the input end of the isolated power supply 1 to the mains AC220V for power supply, and connect the air pressure adjustment device 4 to the gas pipeline 7 at the same time;

[0017] (2) Adjust the pressure value of the air pressure regulating device 4 to 0-5 kilograms per square centimeter. The specific pressure value is determined according to different types of hooks of the electric meter to be assembled, so that the hook of the electric meter can be smoothly pressed into the hook groove of the case of the electric meter middle;

[0018] (3) Place the hook of the electric meter to be assembled facing up in the assembly groove 8 of the assembly device, and then insert the hook of the electric meter to be assemb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com