Vehicle loading and unloading bridge device

A technology for vehicles and steel plates, applied in the field of special logistics equipment, can solve problems such as damage to goods, and achieve the effect of increasing safety, preventing damage and simple operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

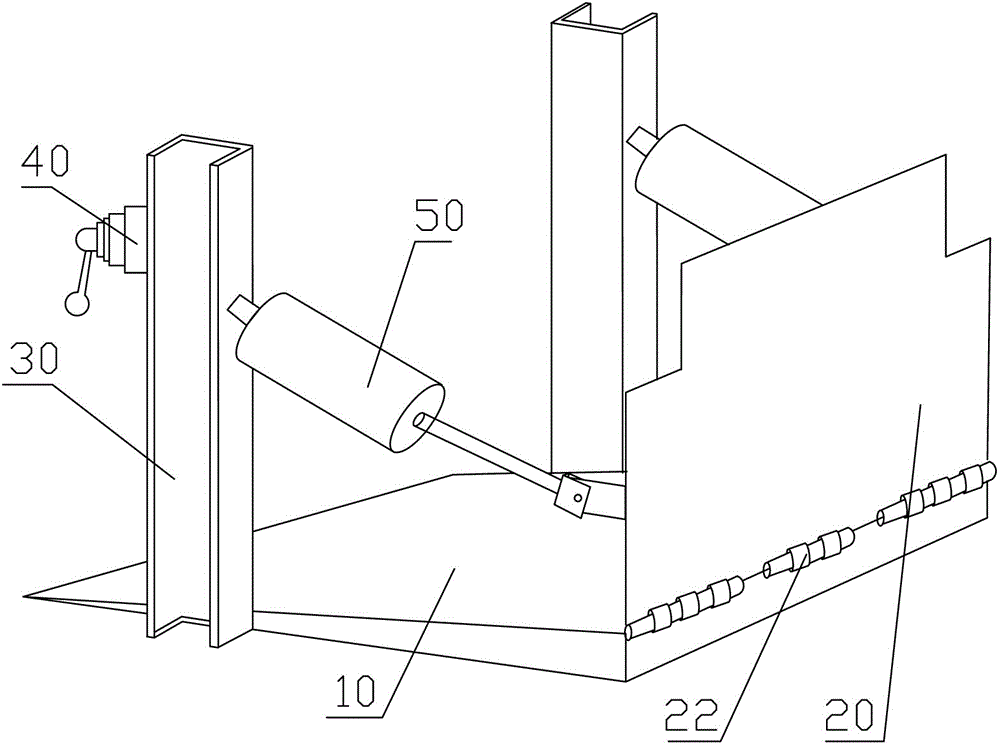

[0043] Such as figure 1 Shown, according to the structural diagram of vehicle loading and unloading bridging device of the present invention. A vehicle loading and unloading bridging device, which includes a platform base 10 and a steel plate 20, the steel plate 20 is connected to the platform base 10 through a pivot pin assembly 22, the forklift will not slip on the platform base 10 during the working process, and it is safe Sex is higher.

[0044] The research and development process of the vehicle loading and unloading bridging device of the present invention is as follows: in actual use, the staff has encountered many problems, and the problems are as follows:

[0045] 1. Since the iron plate is temporarily erected every time it is used, it needs to be manually disassembled after use, which is very inconvenient;

[0046] 2. The goods loaded by the forklift are heavy, and the iron plate is used as the bridge, which is easy to slip, the car body is unstable, and the danger...

Embodiment 2

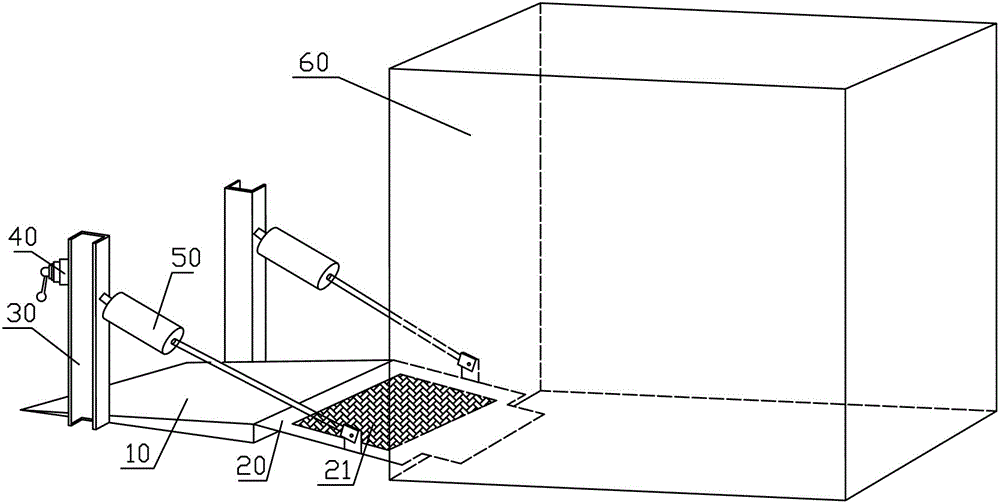

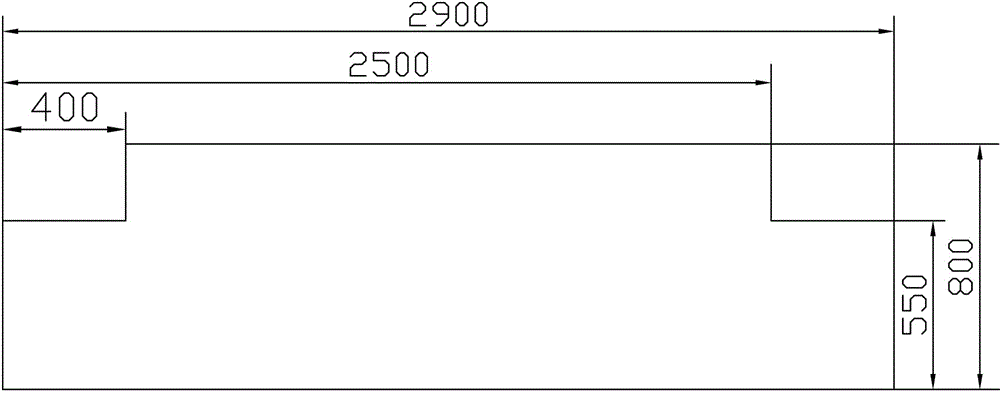

[0093] Such as Figure 7 As shown, this figure is a structural schematic view of another embodiment of the vehicle loading and unloading bridge device of the present invention. When the height of the platform base 10 of the warehouse is low and the height of the car compartment 60 is high, if the technical solution in Embodiment 1 is used, the steel plate 20 needs to be tilted at a certain angle, and at this time the forklift is passing through the steel plate 20 to carry goods , because there is an angled gradient between the steel plate 20 and the automobile compartment 60, it is difficult for the forklift to enter the automobile compartment 60, and there is also a certain danger when the forklift exits from the automobile compartment 60, so the inventor of the present invention A second solution was developed.

[0094] In this embodiment, columns 30 are provided on both sides of the platform base 10 . The column 30 is used to install the reversing air valve 40 and electri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com