Metastable austenite high-boron high-chrome low-carbon wear-resisting alloy steel and preparation method thereof

A metastable austenite, high chromium and low carbon technology, applied in the field of iron and steel materials, to achieve the effect of low production cost, improved impact toughness, high strength and toughness and

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

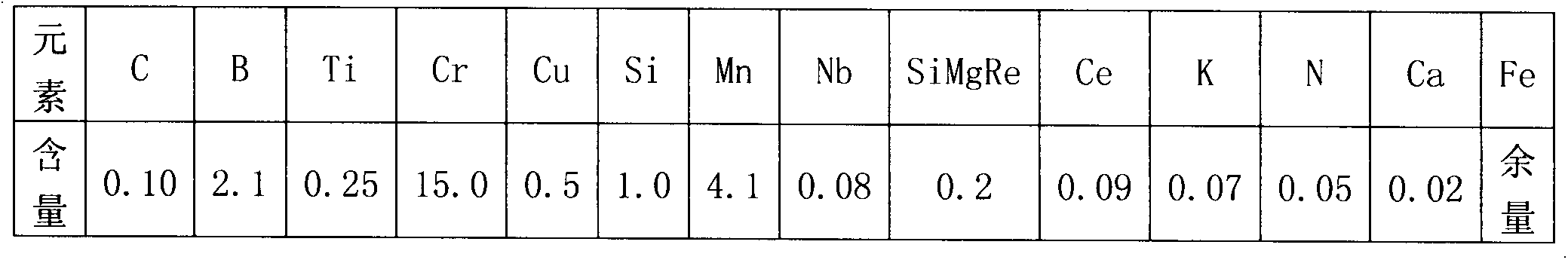

Method used

Image

Examples

Embodiment 1

[0039] (1) Melt scrap steel and ferrochrome in an electric furnace, add copper plate, ferrosilicon and ferromanganese after the molten steel is melted, control the carbon content to meet the requirements, adjust the composition before the furnace to pass, raise the temperature of the melt to 1560~1600℃ , adding silicon-calcium alloy for pre-deoxidation, adding aluminum for final deoxidation, and then sequentially adding ferro-titanium and ferro-boron to melt;

[0040] (2) After all ferro-titanium and ferro-boron are melted, the granular rare earth magnesium alloy less than 12mm and metal cerium and Si 3 N 4 The composite metamorphic inoculant composed of , Nb and K is wrapped with a thin iron sheet, baked at a temperature of 160-200°C, and placed on the bottom of the ladle, and the smelted molten steel is subjected to metamorphic inoculation treatment by the method of pouring into the ladle;

[0041] (3) The molten steel that has undergone metamorphic inoculation treatment in...

Embodiment 2

[0049] (1) Melt scrap steel and ferrochrome in an electric furnace, add copper plate, ferrosilicon and ferromanganese after the molten steel is melted, control the carbon content to meet the requirements, adjust the composition before the furnace to pass, raise the temperature of the melt to 1560~1600℃ , adding silicon-calcium alloy for pre-deoxidation, adding aluminum for final deoxidation, and then sequentially adding ferro-titanium and ferro-boron to melt;

[0050] (2) After all ferro-titanium and ferro-boron are melted, the granular rare earth magnesium alloy less than 12mm and metal cerium and Si 3 N 4 The composite metamorphic inoculant composed of , Nb and K is wrapped with a thin iron sheet, baked at a temperature of 160-200°C, and placed on the bottom of the ladle, and the smelted molten steel is subjected to metamorphic inoculation treatment by the method of pouring into the ladle;

[0051] (3) The molten steel that has undergone metamorphic inoculation treatment in...

Embodiment 3

[0059] (1) Melt scrap steel and ferrochrome in an electric furnace, add copper plate, ferrosilicon and ferromanganese after the molten steel is melted, control the carbon content to meet the requirements, adjust the composition before the furnace to pass, raise the temperature of the melt to 1560~1600℃ , adding silicon-calcium alloy for pre-deoxidation, adding aluminum for final deoxidation, and then sequentially adding ferro-titanium and ferro-boron to melt;

[0060] (2) After all ferro-titanium and ferro-boron are melted, the granular rare earth magnesium alloy less than 12mm and metal cerium and Si 3 N 4 The composite metamorphic inoculant composed of , Nb and K is wrapped with a thin iron sheet, baked at a temperature of 160-200°C, and placed on the bottom of the ladle, and the smelted molten steel is subjected to metamorphic inoculation treatment by the method of pouring into the ladle;

[0061] (3) The molten steel that has undergone metamorphic inoculation treatment in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com