Full-automatic washing machine foam removing system

A fully automatic washing machine and defoaming technology, applied to other washing machines, washing machine control devices, washing devices, etc., can solve the problems of increasing the resistance of the inner tub, increasing the energy consumption of dehydration, and increasing the moisture content of clothes, so as to protect the motor. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be further described below in conjunction with accompanying drawing:

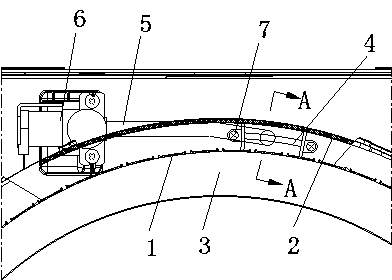

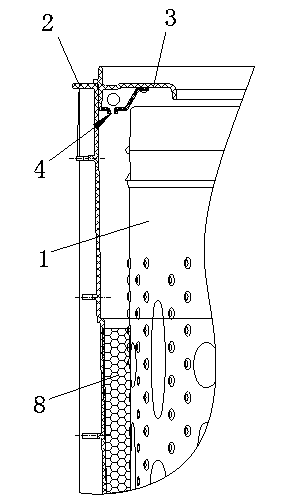

[0012] Such as figure 1 , figure 2 A full-automatic washing machine defoaming system shown includes an inner barrel 1 and an outer barrel 2, an outer barrel cover 3 is arranged above the outer barrel 2, and a nozzle 4 is arranged on the outer barrel cover 3, and the nozzle 4 communicates with the water inlet through the water inlet pipeline 5. The water valve 6 is connected, at least one nozzle 4 is provided, and the injection direction of the nozzle 4 points between the inner tub 1 and the outer tub 2, and the water inlet valve 6 is connected with the controller.

[0013] Further, a plurality of nozzles 4 are evenly arranged along the circumferential direction of the outer barrel cover 3, and the water inlet valve 6 is provided with a plurality of water outlets, and the plurality of nozzles are connected to the water inlet valve through a plurality of water inlet pipelin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com