Small eccentric crank connecting rod transmission mechanism with variable punch length

A technology of crank connecting rod and transmission mechanism, which is applied to punching machines, presses, manufacturing tools, etc., can solve the problems of increased inertia, unfavorable energy saving, affecting the processing performance of punching machines, etc., to protect the motor and drive, improve the degree of automation, Design more humanized effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

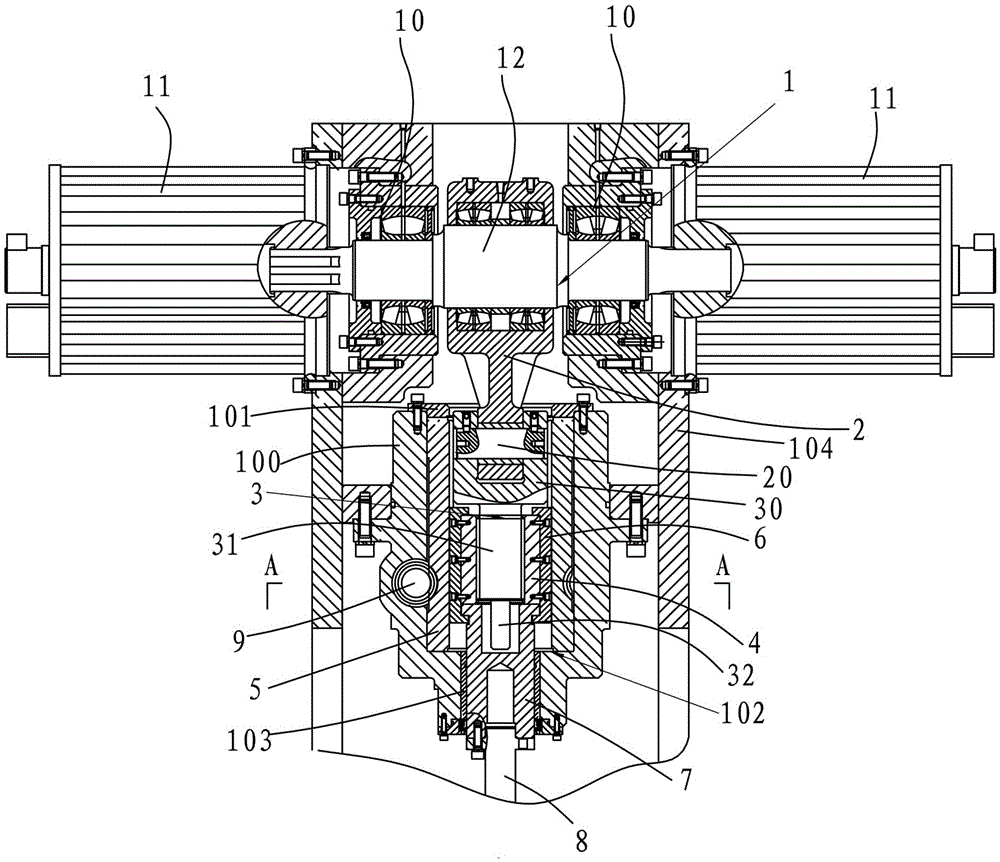

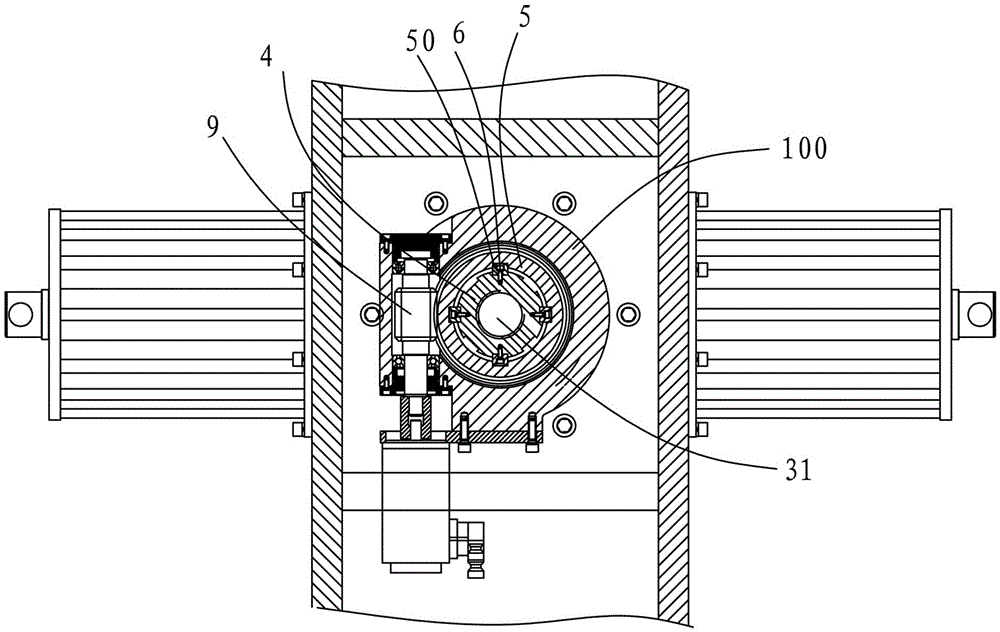

[0022] Example combination figure 1 with figure 2 , a small eccentric crank connecting rod transmission mechanism with variable punch length, including a crankshaft 1, the two circumferential ends of the crankshaft 1 are supported on the bearing housing 10, and motors 11 are installed at the two ends of the crankshaft outside the bearing housing 10, and the crankshaft 1 The eccentric section 12 is provided with the connecting rod 2 . When the crankshaft 1 rotates, the connecting rod 2 rotates with it, so that the connecting rod 2 moves up and down in the height direction.

[0023] The end of the connecting rod 2 is provided with a plunger 3 extending in the axial direction, and the top end of the plunger 3 and the connecting rod 2 are locked by a pin 20 .

[0024] The outer surface of the middle section 31 of the plunger 3 is provided with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com