Lightweight aggregate concrete column with steel-armored corners and fabrication technology thereof

A technology of lightweight aggregate concrete and manufacturing technology, which is applied in the direction of columns, pier columns, pillars, etc., can solve the problems of reduced seismic performance, column self-heaviness, and hindrance to structural applications, etc., to improve the transition zone, good durability, and reduce construction costs. The effect of energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

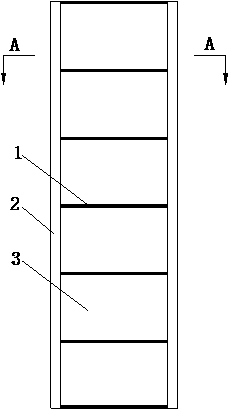

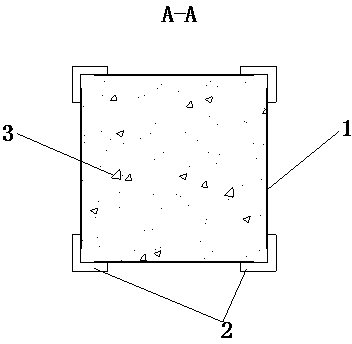

[0024] Such as Figure 1~2 As shown, a corner steel-clad lightweight aggregate concrete column includes a column made of lightweight aggregate concrete 3. The column is covered with angle steel 1 at each corner along its length direction. The surface is higher than the surface of the column or flush with the surface of the column, the inner surface of the angle steel is reliably bonded to the column, and two adjacent angle steels are connected by transverse stirrups 2, which are welded to the two limbs of the angle steel 1. The inner surface.

[0025] In this embodiment, the cross section of the column is polygonal, and the angle formed by the two limbs of each angle steel is equal to the angle of the corresponding corner of the polygon, and may be less than, equal to or greater than a right angle.

[0026] In this embodiment, the lightweight aggregate of the lightweight aggregate concrete 3 is ceramsite, volcanic slag or coal gangue, wherein the ceramsite is one of shale ceramsit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Dry apparent density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com