A microchannel heat exchanger

A micro-channel heat exchanger, heat exchanger technology, applied in evaporator/condenser, lighting and heating equipment, refrigeration components, etc., can solve the problems of heat exchange performance attenuation, large flow pressure drop, system performance attenuation, etc. To achieve the effect of improving heat transfer performance and improving performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be described in more detail below in conjunction with the accompanying drawings.

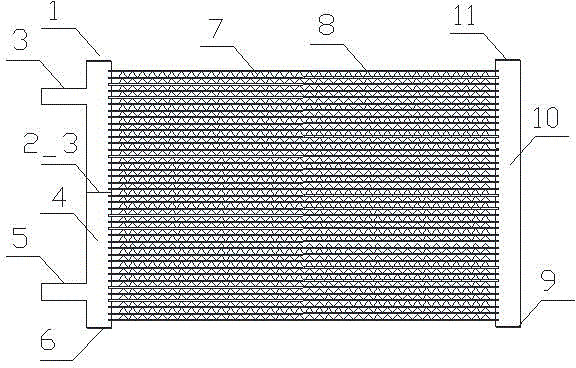

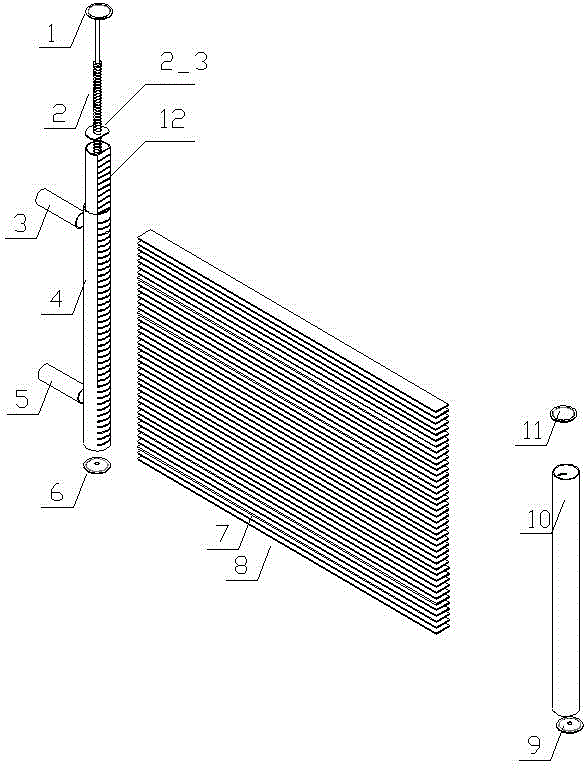

[0019] figure 2 It is a structural exploded schematic diagram of an embodiment of a microchannel heat exchanger in the present invention taking two processes as an example.

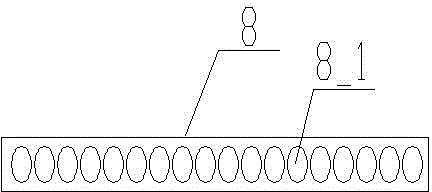

[0020] Such as figure 2 As shown, when the microchannel heat exchanger is running in the refrigeration system, the refrigerant enters the left header 4 and its matching sleeve 12 from the refrigerant inlet pipe 3, and is placed on the first flow regulating device 2. The moving partition 2_3 divides the heat exchanger into two processes. After the refrigerant between the first moving partition 2_3 and the upper left end cover 1 is collected into the right liquid collector 10 through the porous channels on the porous flat tube 8, change Direction: After the refrigerant between the first moving spacer 2_3 and the lower left end cover 6 collects through the porous channel on the porous flat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com