Elastic wiring device

The technology of a wiring device and an elastic wire clamp, which is applied in the electrical field, can solve problems such as the quality of wire fastening cannot be guaranteed, the fastening operation process is inconvenient, and the personal safety of operators cannot be guaranteed, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with the accompanying drawings.

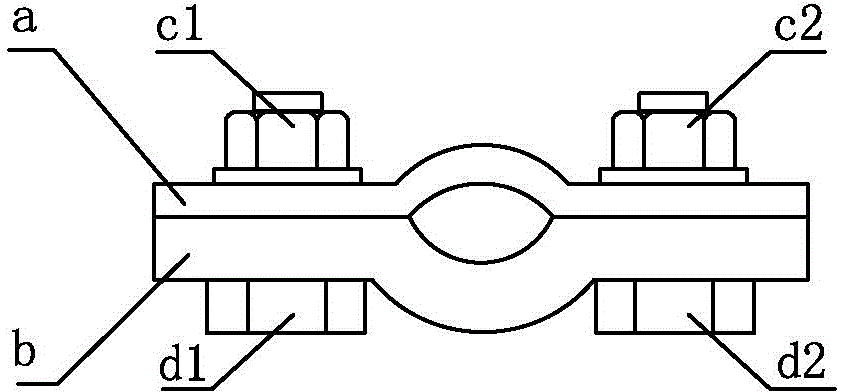

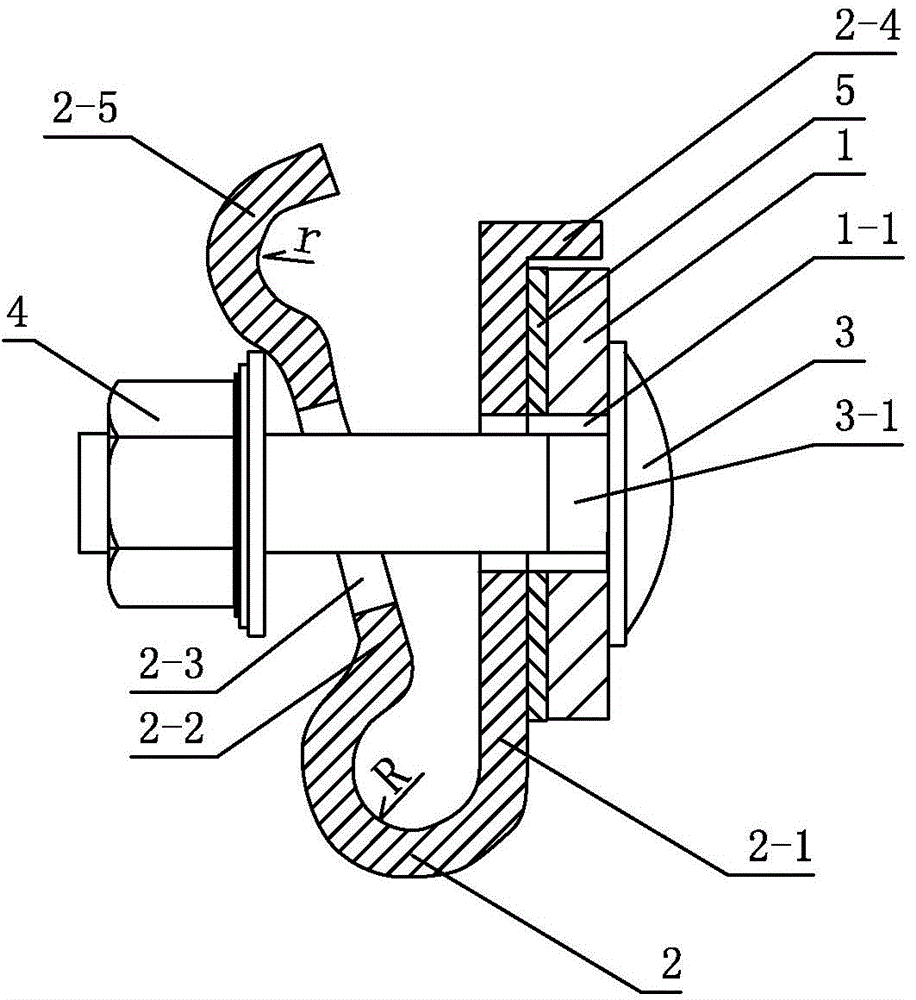

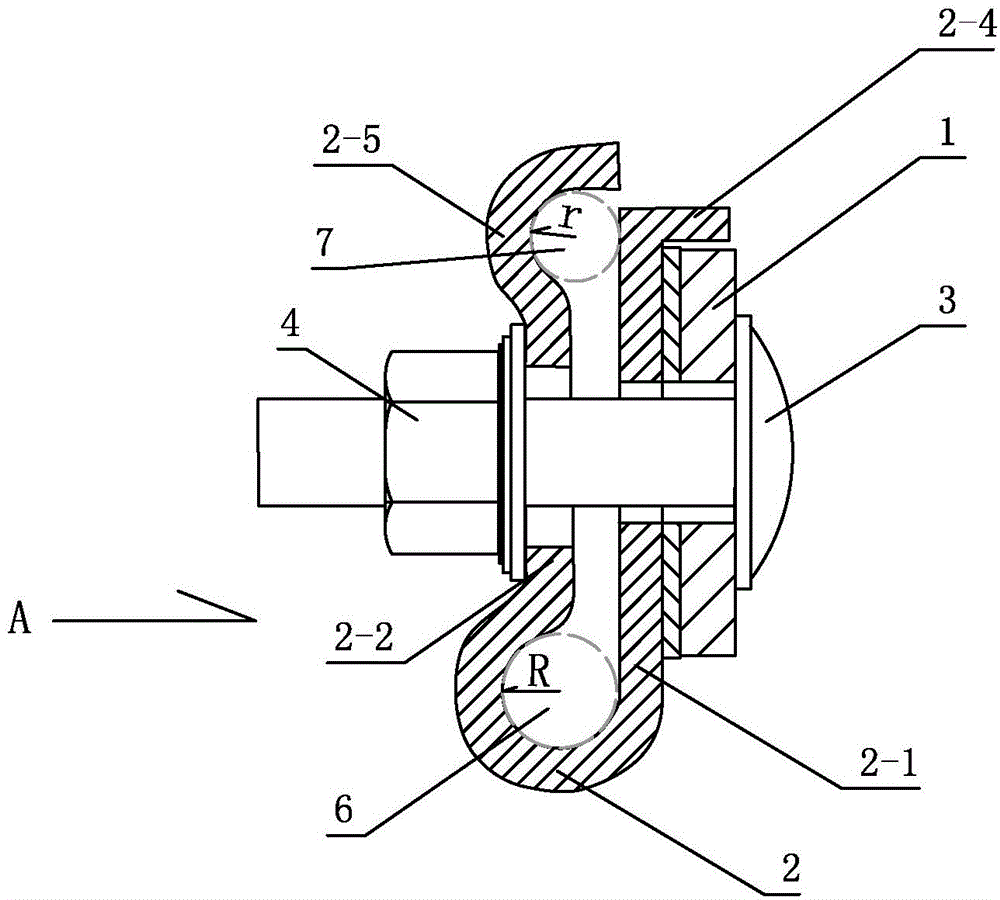

[0027] figure 2 Among them, this technical solution provides an elastic wiring device, which is composed of a C-shaped opening elastic wire clip, a half-round head square neck bolt and a hexagonal flange nut. Square neck bolts and hexagonal flange nuts are fastened on the bracket.

[0028] Among them, the C-shaped opening elastic clamp includes a C-shaped curved surface member 2 with a bending radius of R in the section. At the opening end of the C-shaped curved surface, first and second extended straight sides 2-1 and 2-2 are respectively provided. Bolt holes 2-3 are correspondingly provided on the first and second extended straight sides for passing through the half-round head square neck bolts.

[0029] At the end of the first extended straight side, a limit bending side 2-4 is arranged.

[0030] On the bracket 1, a regular polygonal hole 1-1 is opened.

[0031...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com