Steam spraying device of biomass gasification furnace

A technology of injecting steam into the gasification furnace, which is applied in the manufacture of combustible gas and the petroleum industry, etc. It can solve the problems of slow efficiency and low calorific value, achieve the effect of convenient and simple operation, and increase the calorific value of straw gas

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

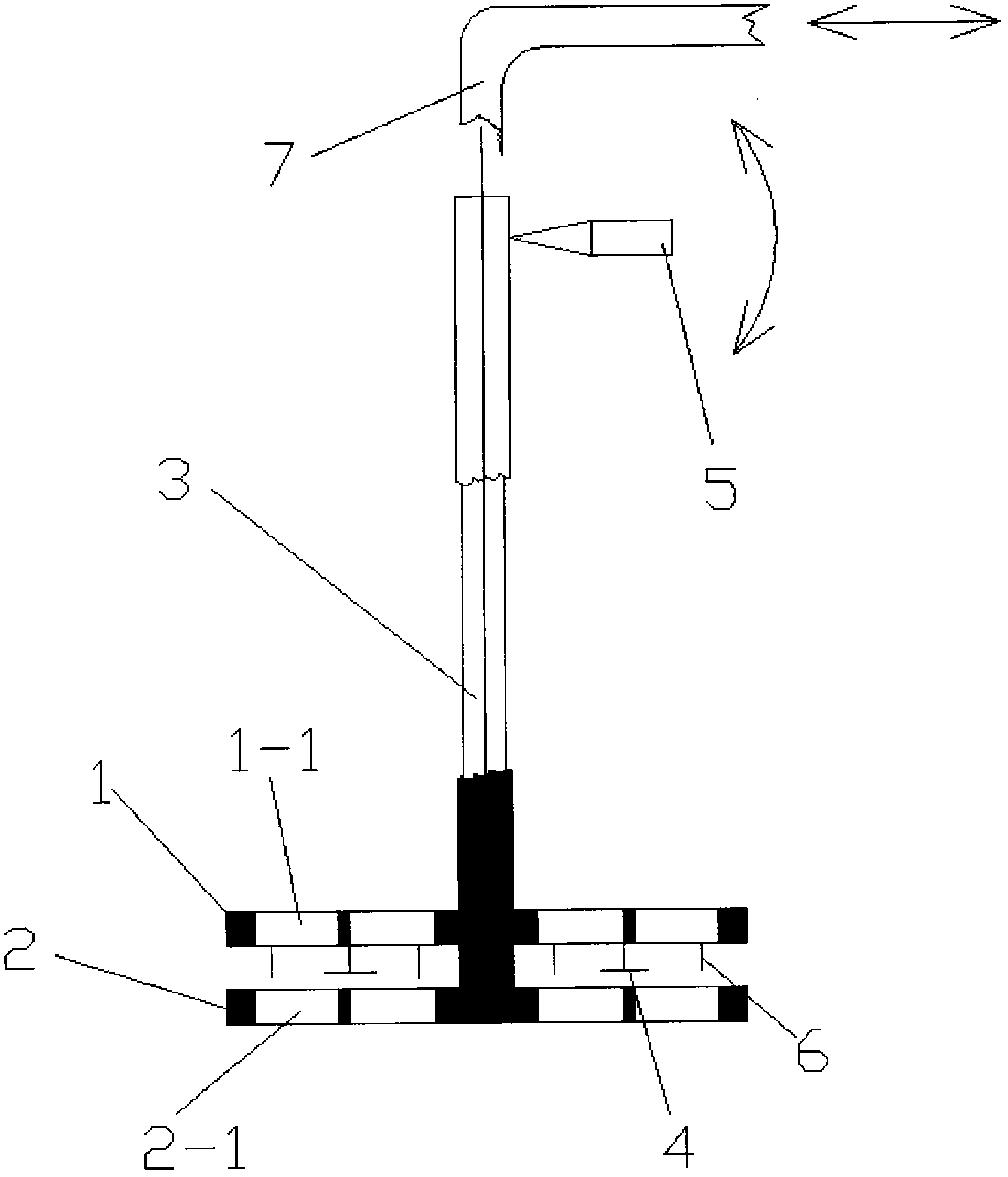

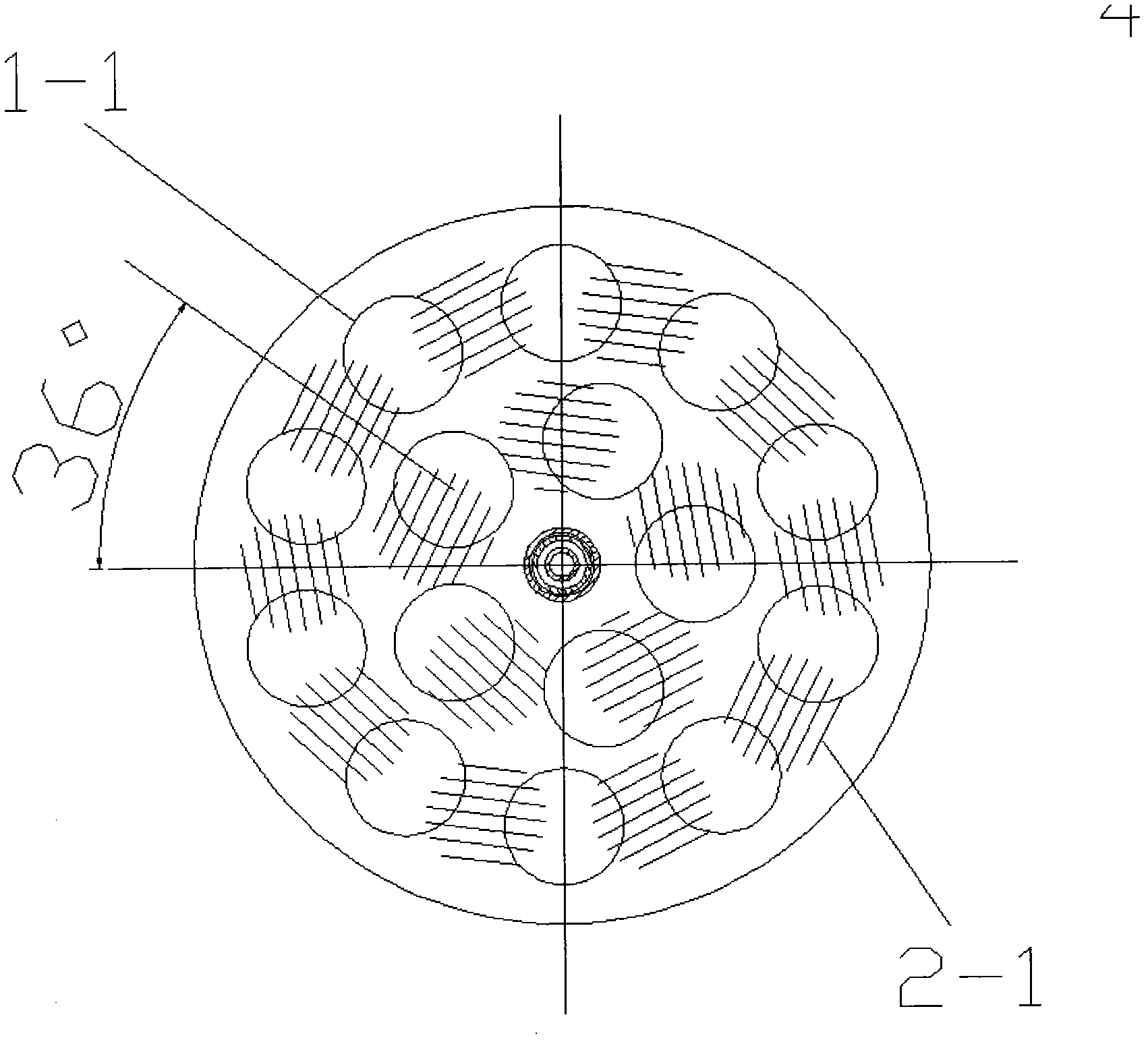

[0022] Such as figure 1 As shown, the present invention provides a steam injection device for a biomass gasifier, the device includes an upper hanging pan 1, a lower hanging pan 2, a steam pipeline 3 and a steam nozzle 4 communicating with the steam pipeline, the upper hanging pan and the lower hanging pan. The hanging pans are equal in size and have the same structure, and they are all circular pans. The circular pans are evenly provided with feeding holes 1-1, 2-1. The lower hanging pans are fixedly installed, and the upper hanging pans are connected with a rotating handle 5 to make the upper hanging pans Rotate freely within 36 degrees, and a plurality of steam nozzles and temperature control probes 6 are installed on the bottom surface of the upper hanging pan and the top of the lower hanging pan.

[0023] Such as figure 1 As shown, the upper hanging plate and the lower hanging plate are connected with a circulating cooling water pipeline 7.

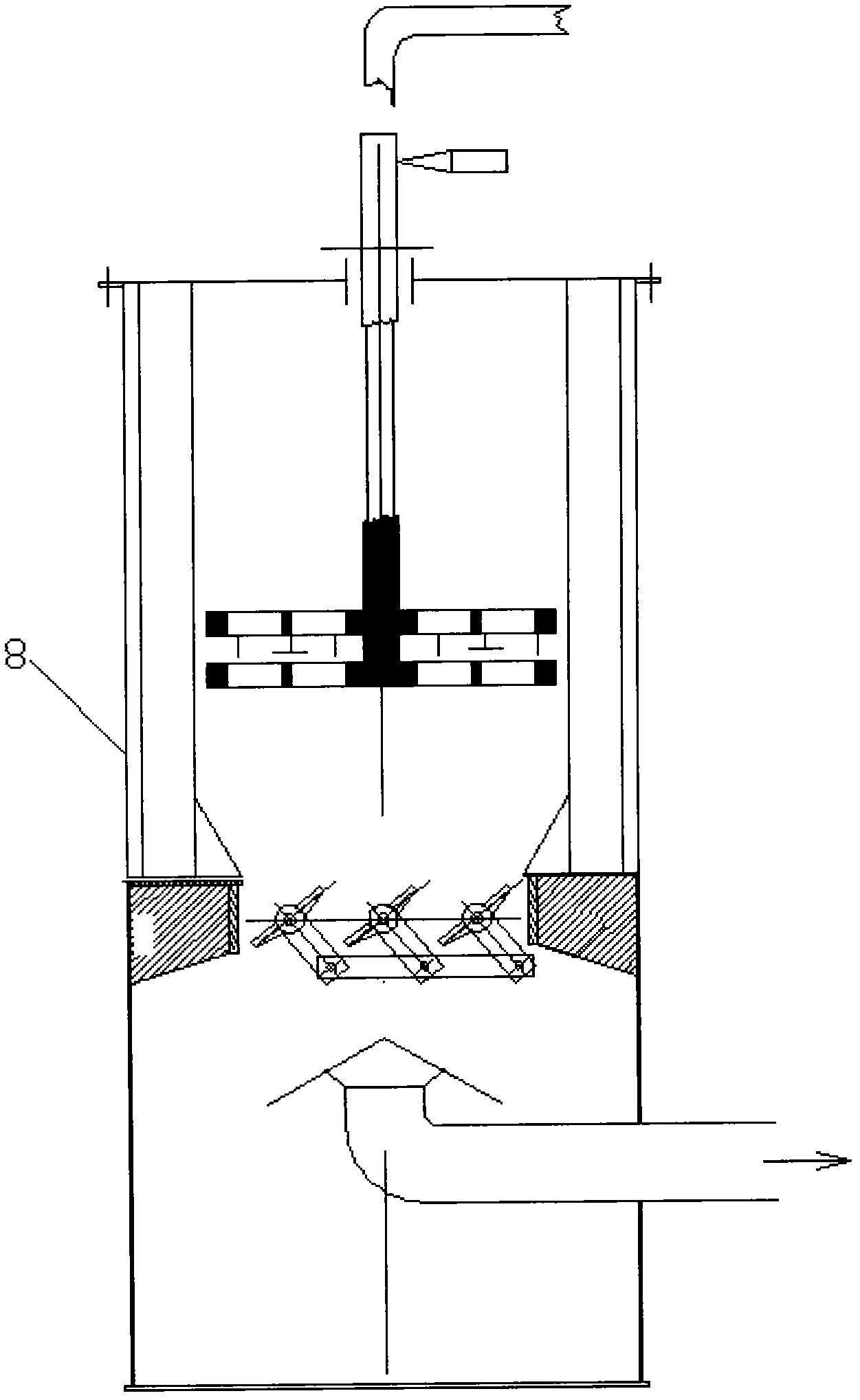

[0024] Such as image 3 As...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com