Lamp power control circuit

A technology for controlling circuit and lamp power, applied in electric light sources, electrical components, gas discharge lamps, etc., can solve the problems of iron core heating energy, large short-circuit current, waste and other problems, and achieve the effect of saving electricity and protecting bulbs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

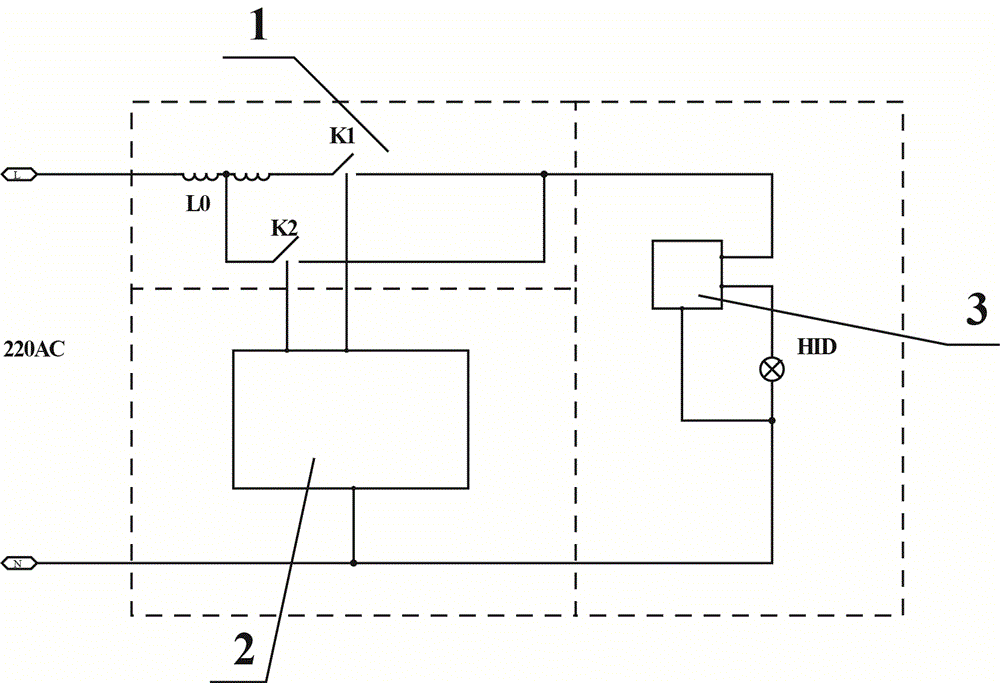

Embodiment 1

[0021] like figure 1 , the mains 220 volt AC live wire L is connected to the left end of the magnetic ballast L0, the right end of the magnetic ballast L0 is connected to the left end of the first switching tube K1, and the middle tap of the magnetic ballast L0 is connected to the left end of the second switching tube K2, The right end of the first switching tube K1 and the right end of the second switching tube K2 are connected to each other and then connected to the input end of the starter 3, the output end of the starter 3 is connected to one end of the bulb HID, and the other end of the bulb HID is connected to the mains 220 volts AC zero Line N.

[0022] The first switching tube K1 and the second switching tube K2 are respectively connected to the controller 2 .

[0023] The starter 3 and the controller 2 are also respectively connected to the neutral line N of the 220-volt alternating current of the commercial power.

Embodiment 2

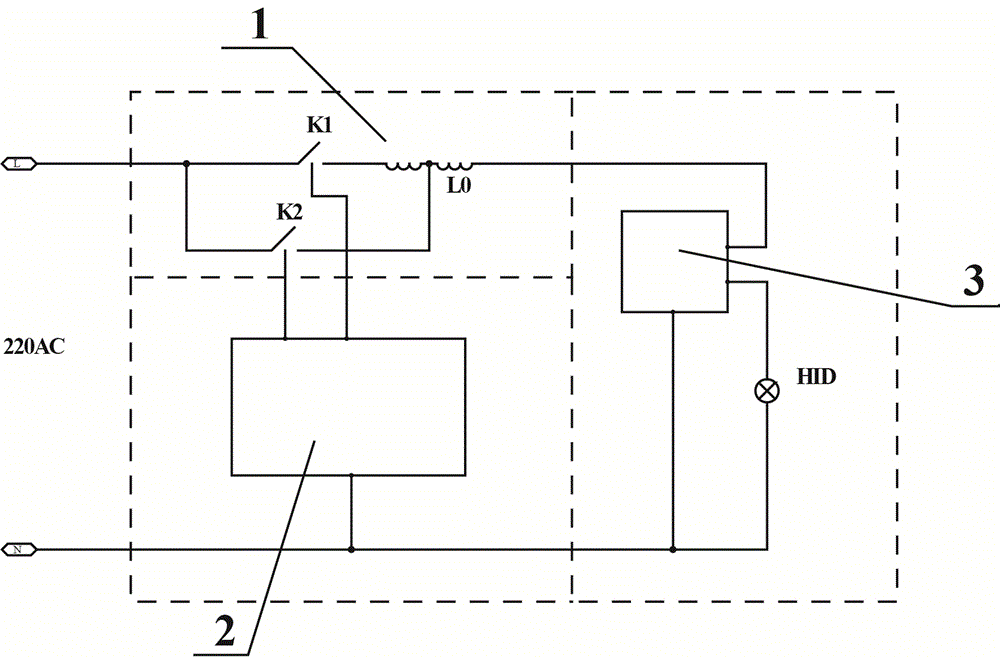

[0025] like figure 2 , the left end of the magnetic ballast L0 is connected to the right end of the first switching tube K1, the middle tap of the magnetic ballast L0 is connected to the right end of the second switching tube K2, and the left end of the first switching tube K1 is connected to the left end of the second switching tube K2. After connection, connect to mains 220V AC live wire L. The right end of the magnetic ballast L0 is connected to the input end of the starter 3, the output end of the starter 3 is connected to one end of the bulb HID, and the other end of the bulb HID is connected to the mains 220V AC neutral line N.

[0026] The first switching tube K1 and the second switching tube K2 are respectively connected to the controller 2 .

[0027] The starter 3 and the controller 2 are also respectively connected to the neutral line N of the 220-volt alternating current of the commercial power.

Embodiment 3

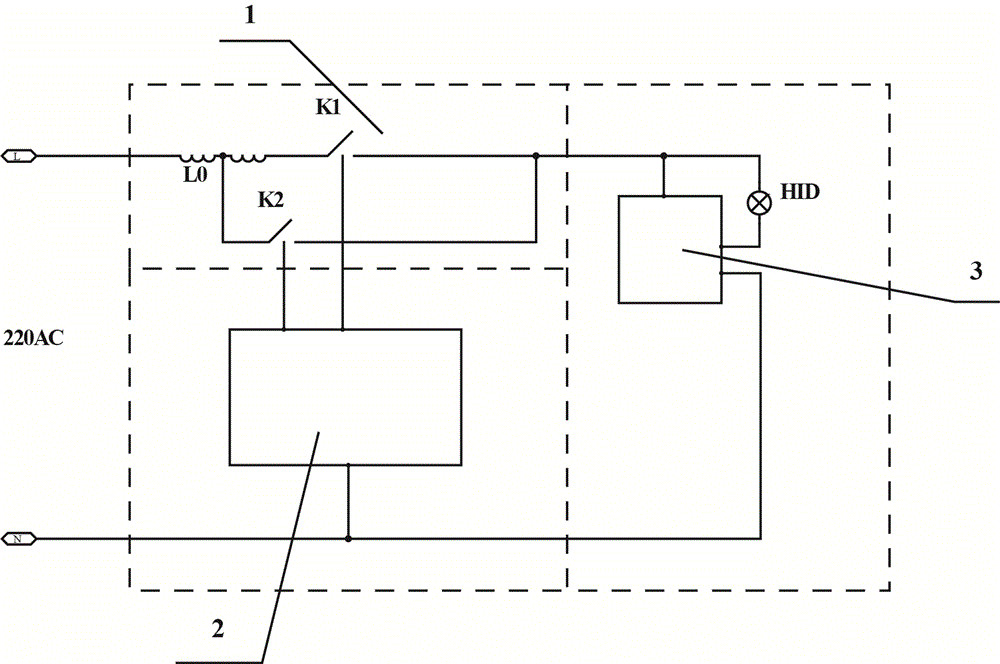

[0029] like image 3 , the mains 220 volt AC live wire L is connected to the left end of the magnetic ballast L0, the right end of the magnetic ballast L0 is connected to the left end of the first switching tube K1, and the middle tap of the magnetic ballast L0 is connected to the left end of the second switching tube K2, The right end of the first switching tube K1 and the right end of the second switching tube K2 are connected to each other and then respectively connected to one end of the starter 3 and one end of the bulb HID, and the other end of the bulb HID is connected to the other end of the starter 3 .

[0030] The first switching tube K1 and the second switching tube K2 are respectively connected to the controller 2 .

[0031] The starter 3 and the controller 2 are also respectively connected to the neutral line N of the 220-volt alternating current of the commercial power.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com