Pin pulling device

A technology of guide parts and guide holes, which is applied in the direction of hand-held tools and manufacturing tools, can solve problems such as difficult pin extraction, and achieve the effect of solving difficult pin extraction, simple operation, and convenient clamping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, but it should be understood that the protection scope of the present invention is not limited by the specific embodiments.

[0021] The pin pulling device of the present invention is mainly designed for the difficulty in extracting the existing pins, by designing the chuck to clamp the exposed part of the pin, and then driving the chuck to move through the threaded sleeve to take out the pin. The device can be operated on an in-situ production line without being limited by time and place, and the device is easy to operate and has high efficiency. In addition, the device will not damage the pins and save costs.

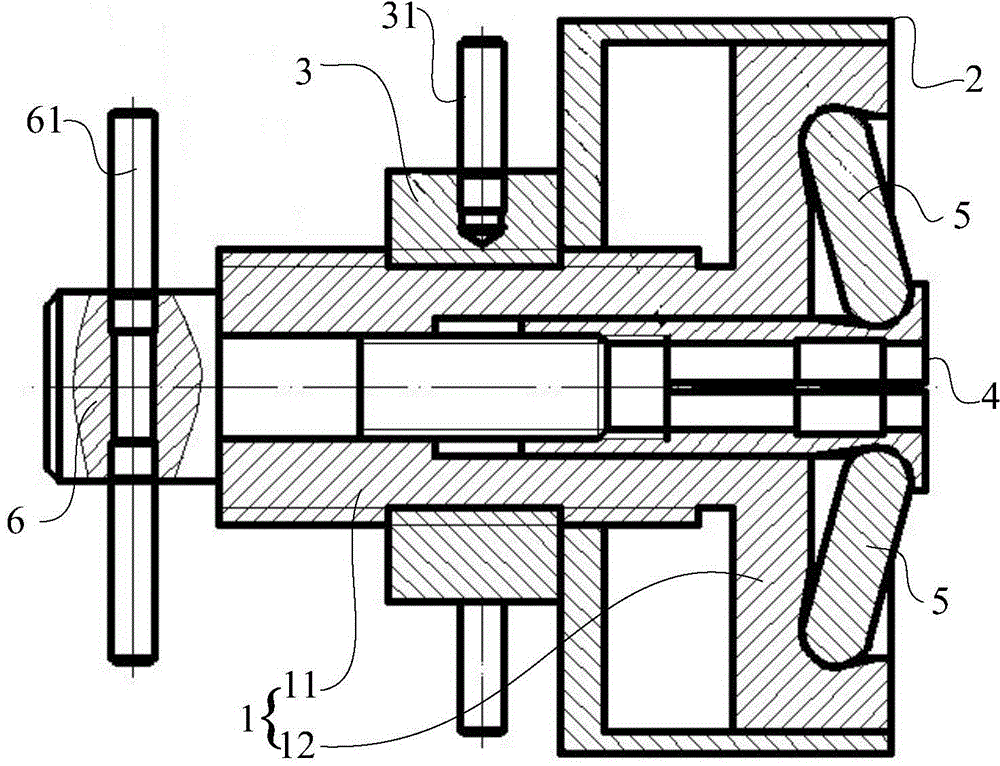

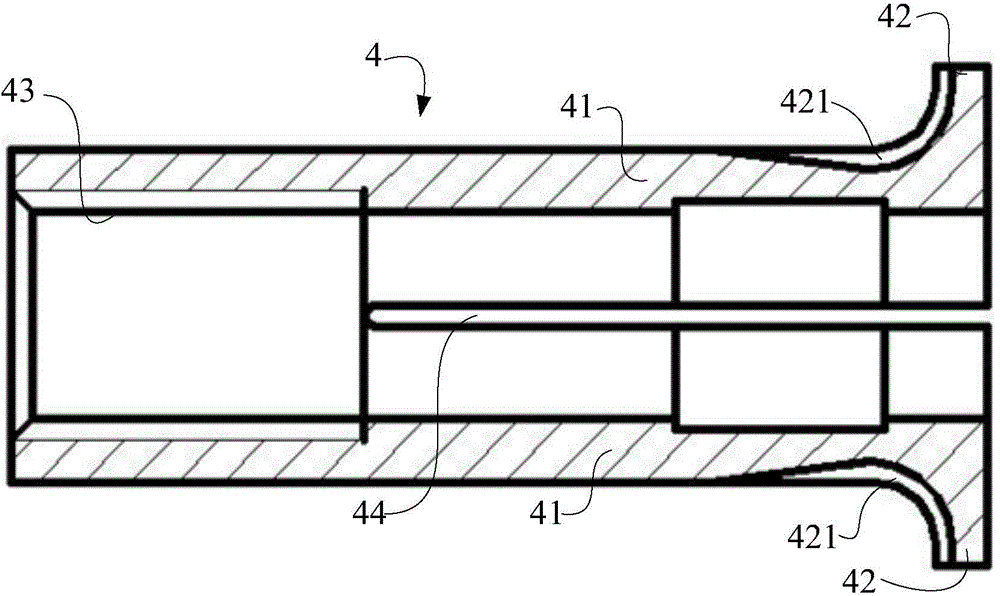

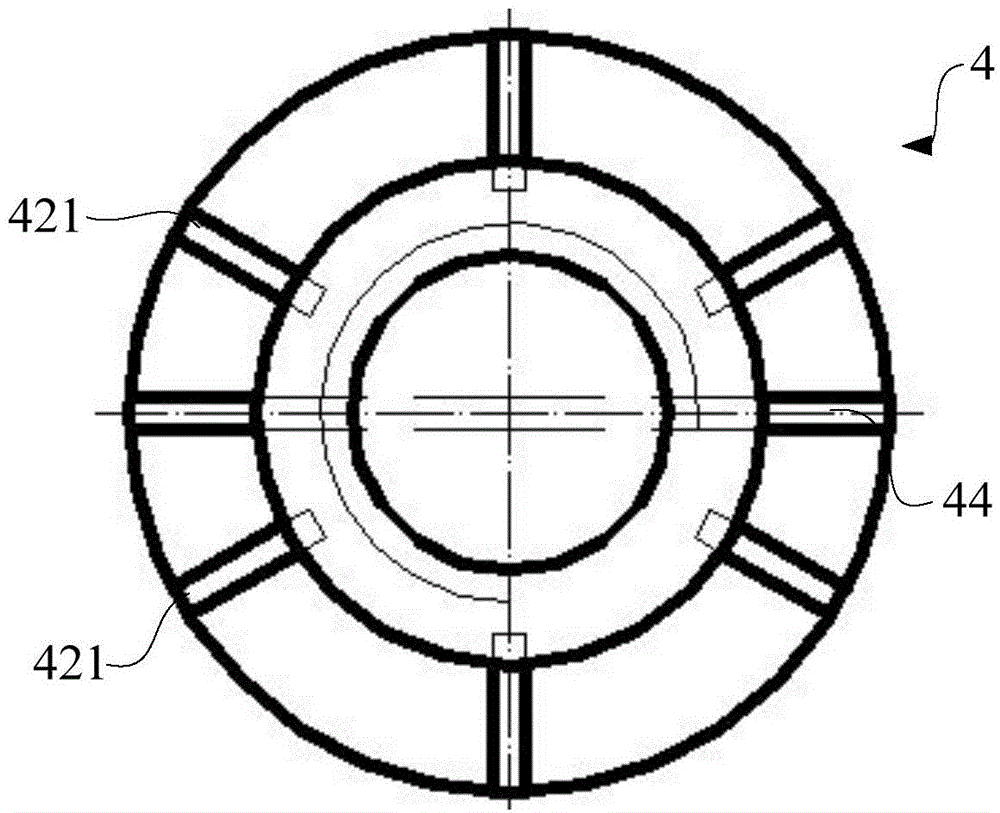

[0022] like figure 1 As shown, the pin pulling device of the present invention includes a main body 1, a support sleeve 2, a threaded sleeve 3, a chuck 4, a fan piece 5 and a rotating head 6. The main body 1 specifically includes an ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com