Strip-shaped material conveying and distributing mechanism

A technology of material distribution mechanism and feeding conveyor belt, which is applied in packaging and other directions, and can solve problems such as low work efficiency, high labor intensity of workers, storage hygiene problems, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

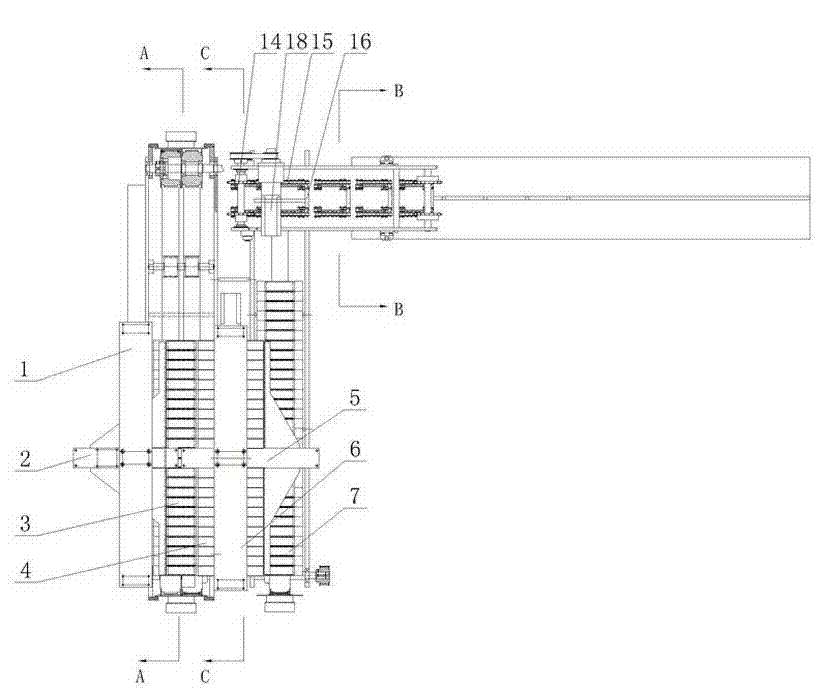

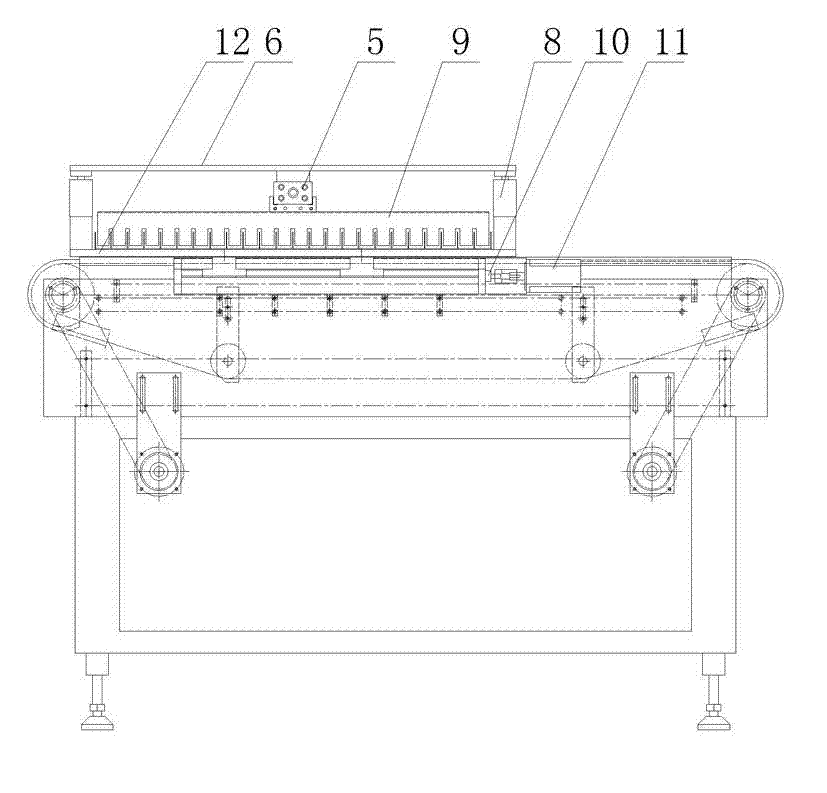

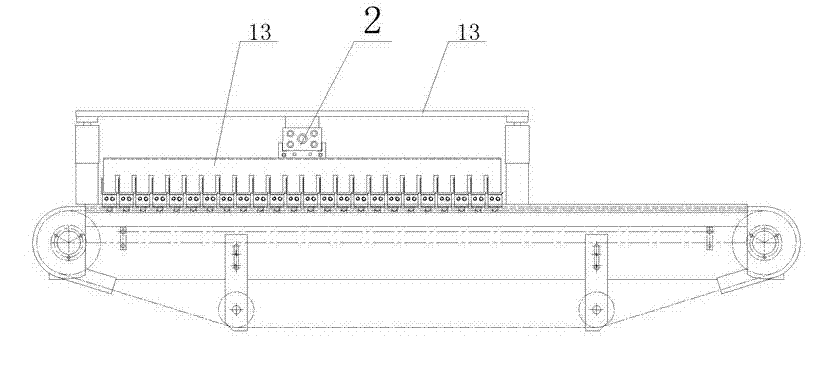

[0014] With reference to the accompanying drawings, this strip-shaped material conveying and distributing mechanism has a frame 1, a feed conveyor belt 3 and a discharge conveyor belt 7, and the feed conveyor belt 3 and the discharge conveyor belt 7 are installed on the machine respectively. The both sides of frame 1, namely the feed conveyer belt 3 is installed on one side of frame 1, and the discharge conveyer belt 7 is installed on the other side, the feed conveyer belt 3 among the present invention and the discharge conveyer belt 7 all are carried out intermittently transmission. A movable material compensation device that can transfer materials to the discharge conveyor is provided between the feed conveyor belt 3 and the discharge conveyor belt 7, and a push cylinder is provided on one side of the feed conveyor belt 3 2. Install the cylinder connecting plate 13 on the frame 1, the pushing cylinder 2 is fixed on the cylinder connecting plate 13, and the push rod of the pu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com