Adjusting device for motor vehicle headlights

A technology for adjusting devices and motor vehicles, which is applied in the directions of motor vehicles, lighting devices, signal devices, etc., to achieve the effect of improving repeatability and improving the load capacity of machinery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

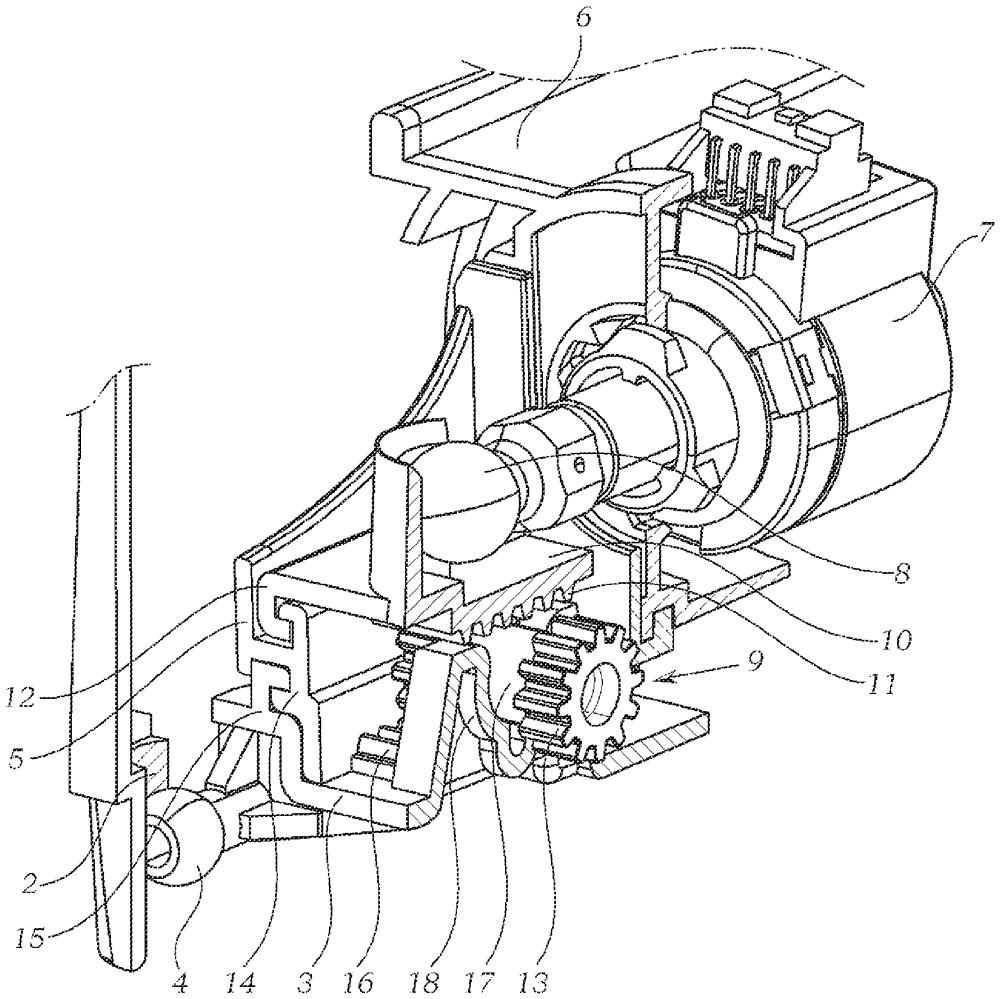

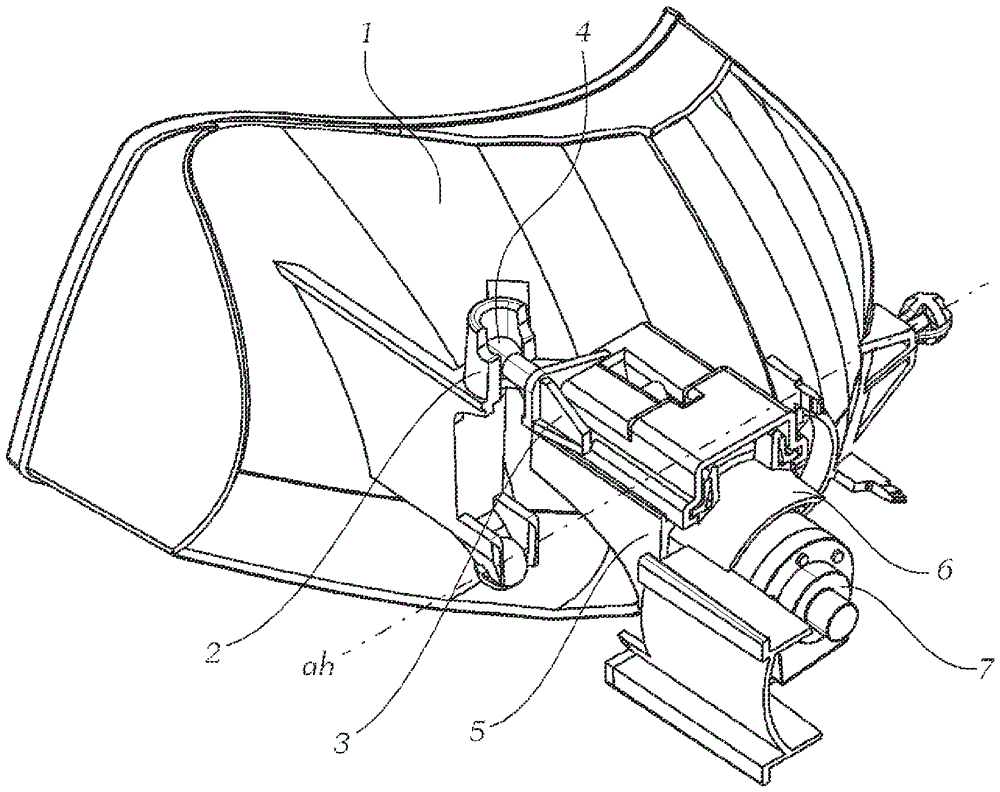

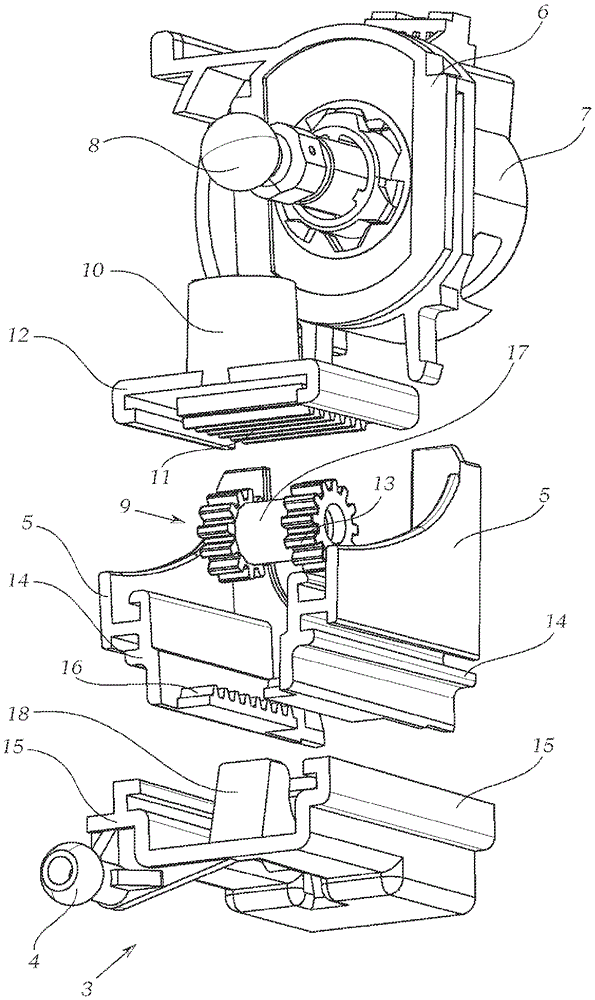

[0043] exist figure 1 shows a headlight reflector 1 , which here is an optically relevant component 1 within the meaning of the invention, and a non-limiting embodiment of the adjusting device according to the invention can be seen (see also Figure 2 to Figure 5 ). The viewing direction is here from below. Reference is made here to all the descriptions provided that no other reference is made to the state of installation of the motor vehicle headlight in the motor vehicle. exist figure 1 In this case, the headlight reflector 1 has an adjusting head receptacle 2 arranged on the headlight reflector 1 , by means of which the headlight reflector 1 engages with the adjusting head 4 of the adjusting element 3 . The headlight reflector 1 is movable here about the horizontal axis ah. The adjusting head 4 protrudes into the adjusting head receptacle 2 , by means of which the adjusting head 4 is at least partially enclosed, whereby a linear movement of the adjusting head 4 is conve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com