Secondary cooling system of bulb cross-flow hydrogenerator

A water turbine generator and secondary cooling technology, which is applied in the direction of cooling/ventilation devices, electrical components, electromechanical devices, etc., can solve the problem of increased number of shutdowns, high maintenance costs of air coolers, easy fouling of air coolers, Blockage and other problems, to achieve the effect of convenient maintenance and operation, considerable economic benefits, and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

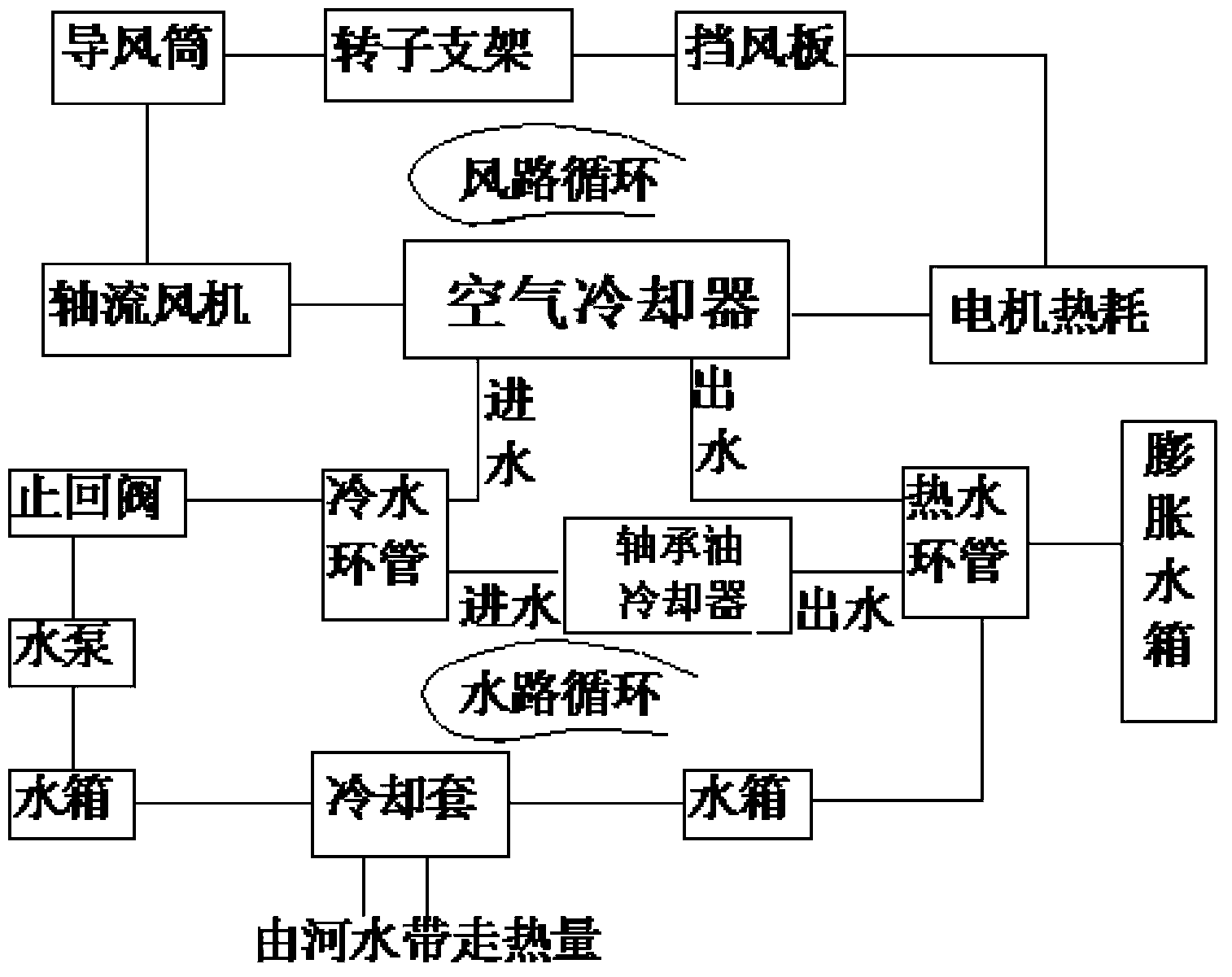

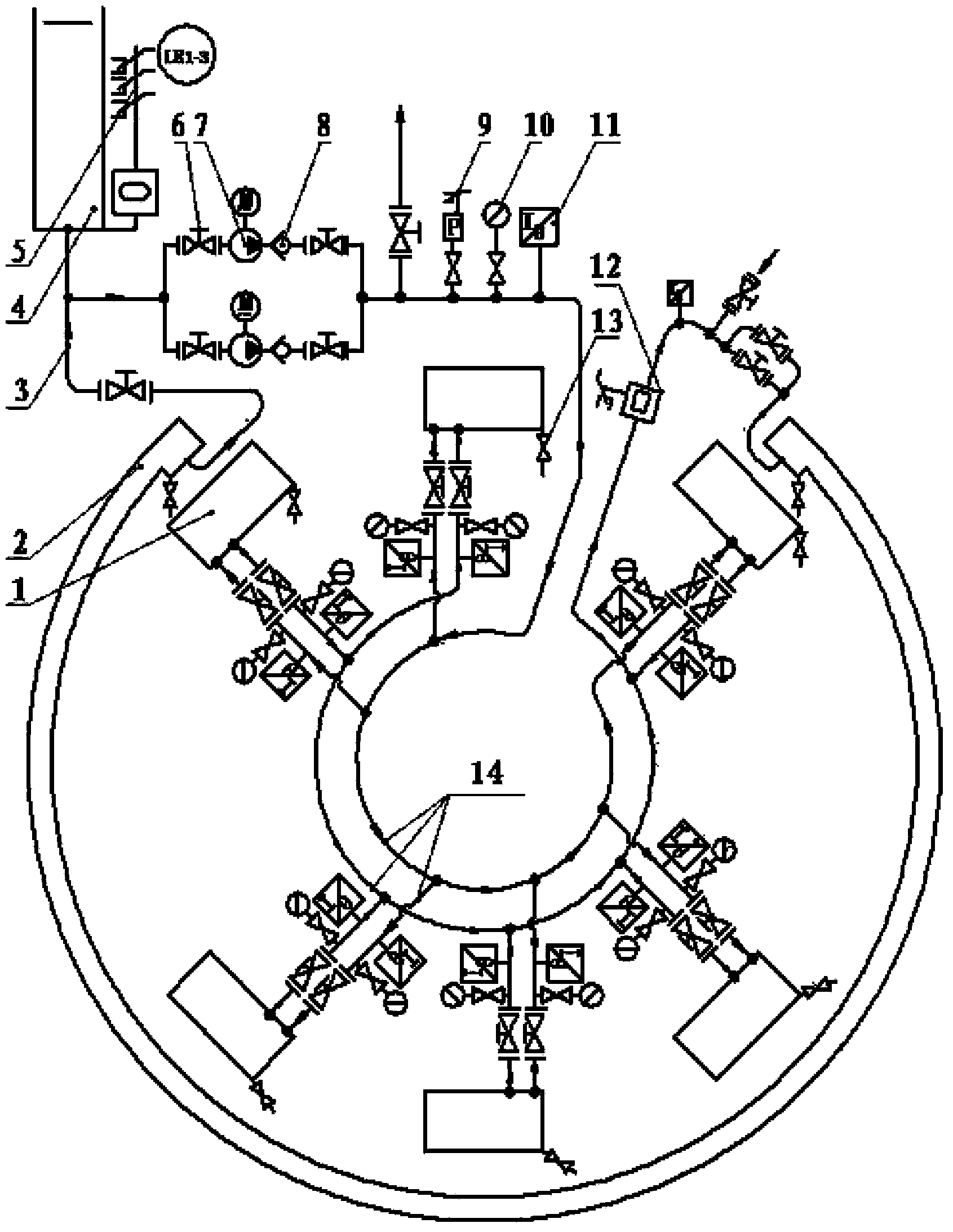

[0021] like figure 1 , 2 As shown, the present invention provides a secondary cooling system for bulb tubular hydroelectric generators. The cold water in the air cooler 1 is used to perform primary air circulation heat exchange on the hot air generated by generator loss. After heat exchange, the air The hot water produced by the cooler 1 and the bearing oil cooler is sent to the cooling jacket 2 of the unit bubble head through the water diversion ring pipe 14. The water diversion ring pipe 14 includes a cold water ring pipe and a hot water ring pipe, and the river water in the flow channel The hot water in the cooling jacket 2 is subjected to secondary water circulation heat exchange, and the heat is taken away by the river water, and then the cold water is injected back into the bearing oil cooler through butterfly valve 6, centrifugal water pump 7, check valve 8, water diversion pipe and other equipment, As a result, the electric motor is cooled by circulation.

[0022] Fu...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap