Movable pebble coal sealing collector

A collector and pebble coal technology, applied in grain processing and other directions, can solve problems such as harm to the health of workers, harsh working environment, and low work efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

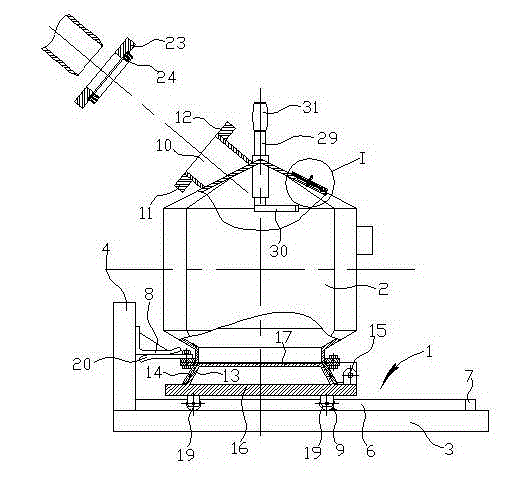

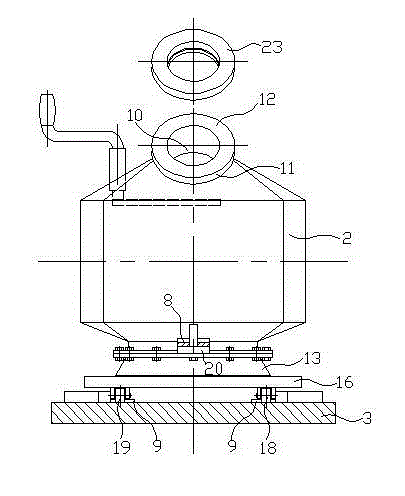

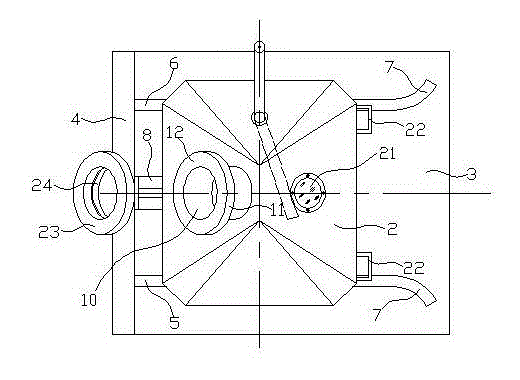

[0031] Figure 1~Figure 8 middle,

[0032] The movable gravel coal seal collector has a slideway plate 1 and a box body 2 that can slide on the slideway plate,

[0033] The slideway plate has a horizontal rectangular flat plate 3, and the top of the front edge of the flat plate has a vertical plate 4 perpendicular to the flat plate, and left and right retaining strips 5,6 parallel to the side are arranged on the flat plate, and the rear section of the retaining strip has outwardly curved Limit 7, there is block 8 parallel with flat plate behind the vertical plate, and the left and right retaining bar inboards above the flat plate have block 9 respectively,

[0034] On the top of the box body there is a circular tube-shaped feeding port 10 facing upwards obliquely, the nozzle of the feeding port has a connecting ring 11, and the upper side of the connecting ring has a circular sealing surface perpendicular to the axis of the round tube of the feeding port 12. The lower end of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com