Tire mold side plate, tire mold and machining method

A tire mold and processing method technology, applied in tires, household appliances, other household appliances, etc., can solve problems such as inconvenience in processing, and achieve the effects of neat appearance, lower production costs, and better appearance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

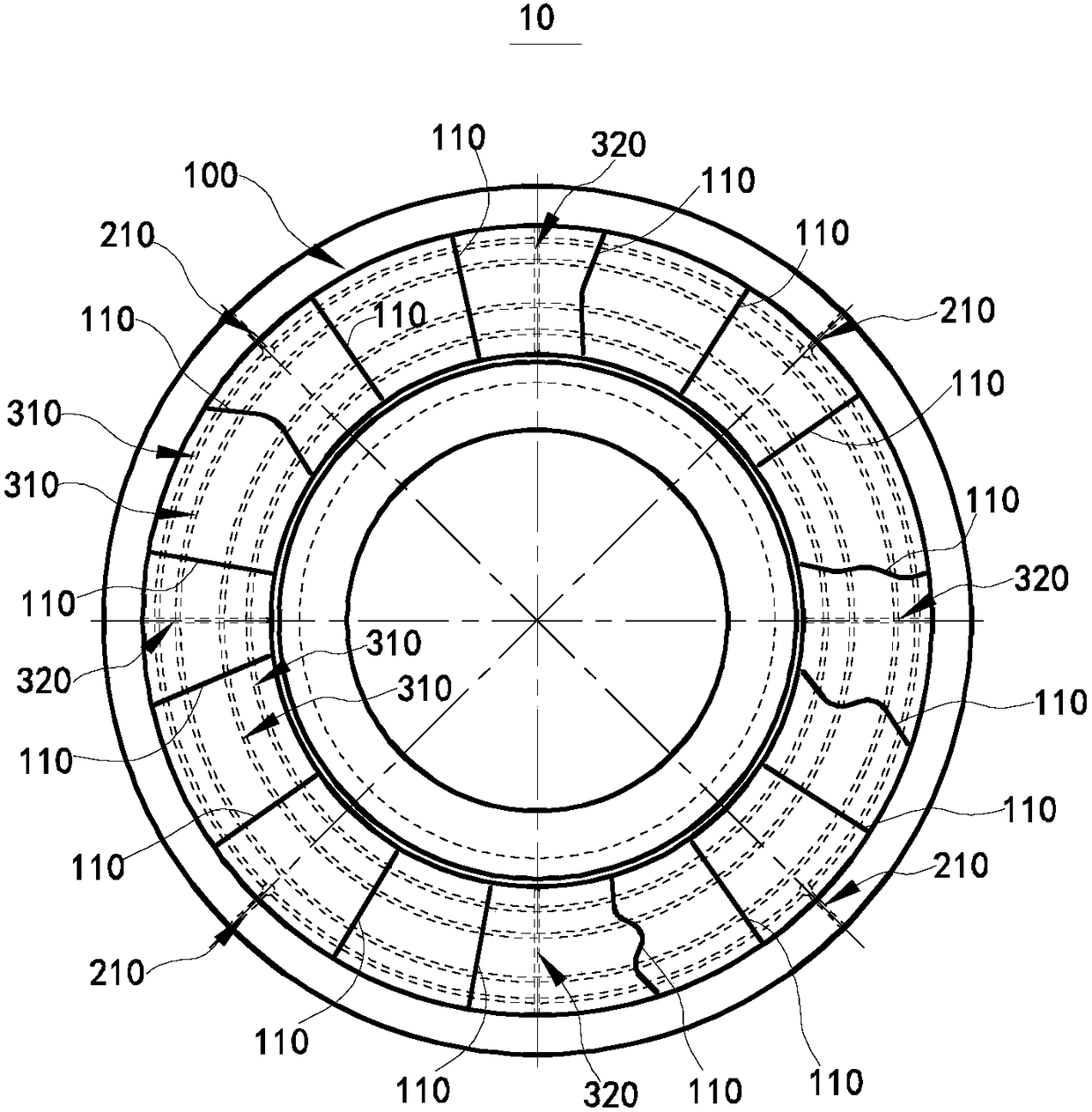

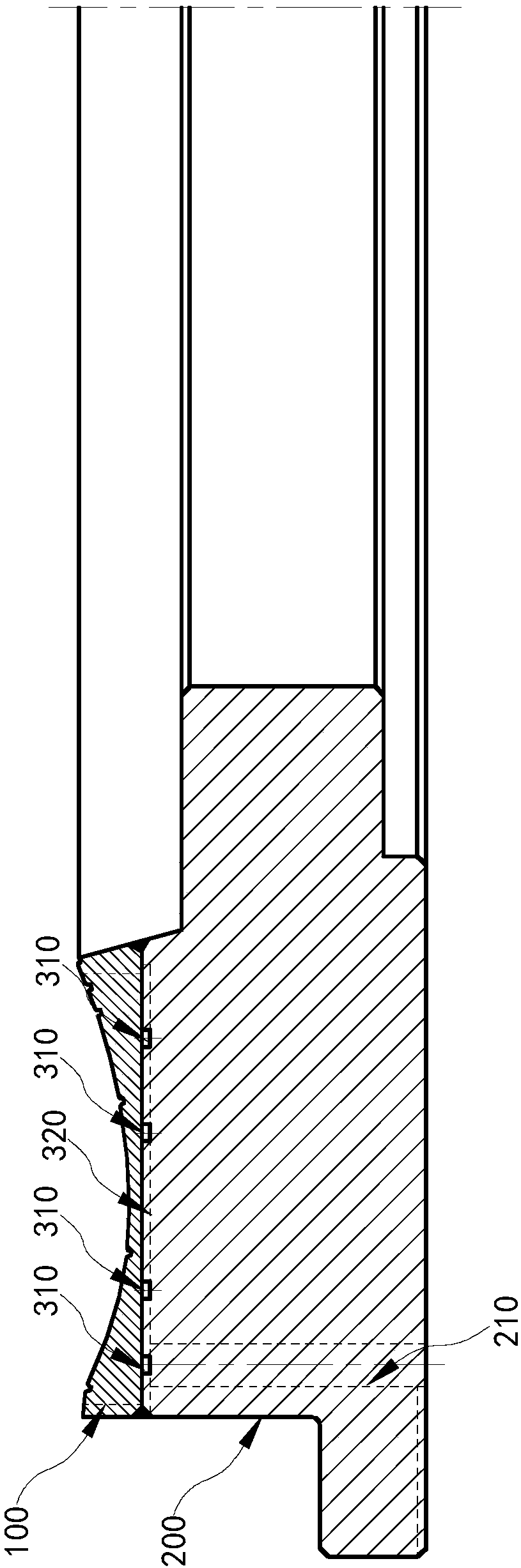

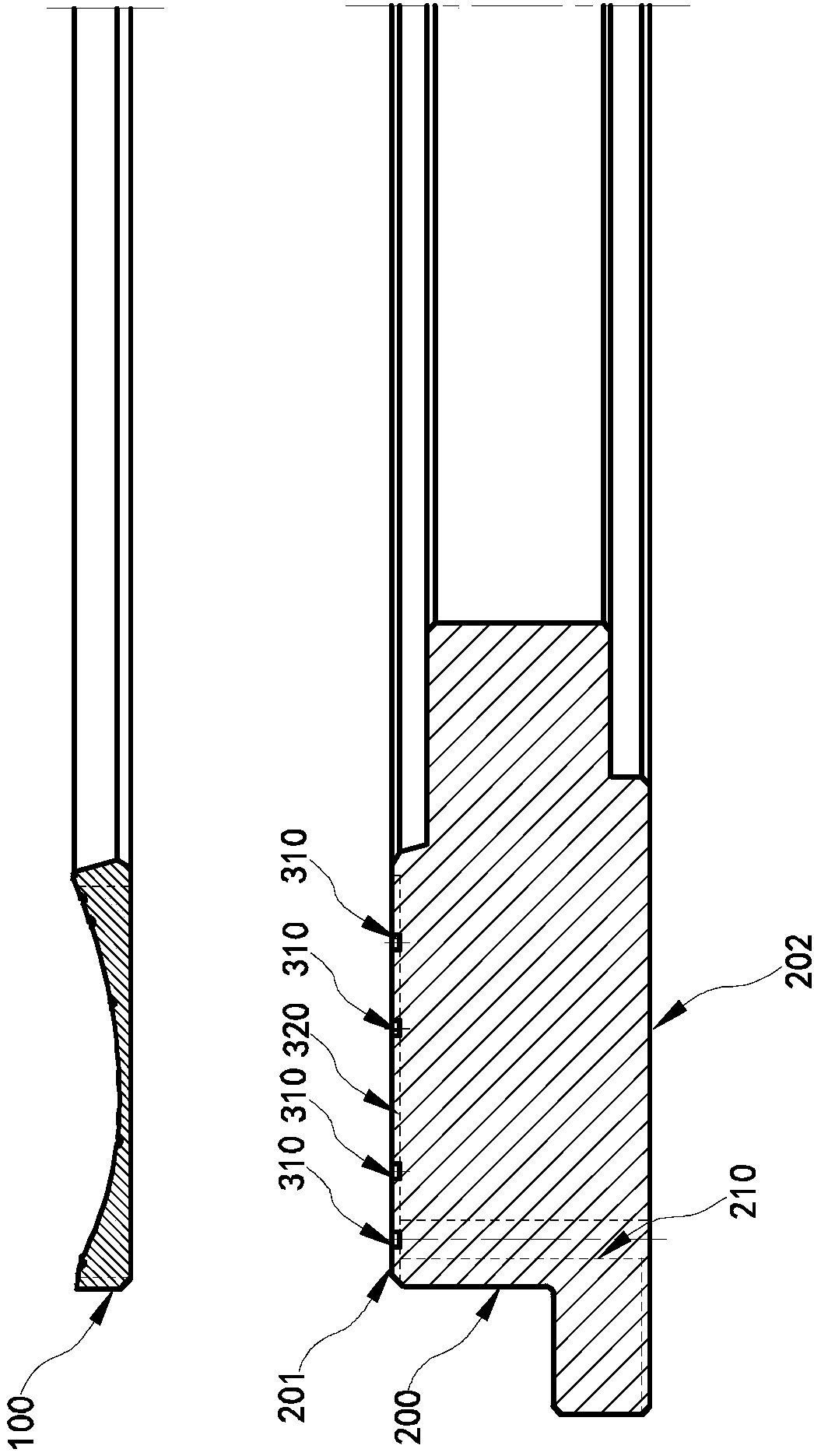

[0065] figure 1 It is a schematic structural diagram of a tire mold side plate 10 provided in an embodiment of the present invention. figure 2 for figure 1 Schematic diagram of the structure from another perspective. image 3 for figure 2 Schematic diagram of the assembly. Please refer to Figure 1-Figure 3 , a tire mold side panel 10 can be seen from the figure, which includes a cavity panel 100 , a connecting portion 222 and a side panel body 200 .

[0066] The side plate body 200 has an inner side 201 close to the green tire and an outer side 202 away from the green tire;

[0067] The cavity panel 100 is disposed on the inner side surface 201 of the side plate body 200 through the connecting portion 222 ; the cavity panel 100 is provided with an exhaust gap 110 , and the exhaust gap 110 is from the side away from the side plate body 200 to the direction close to the side plate body 200 It runs through the cavity panel 100; the cavity panel 100 is provided with patte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com