Cold pilger mill feed-in mechanism

A technology of cold rolling mill and feeding mechanism, applied in metal rolling, metal rolling, metal processing equipment and other directions, can solve problems such as connection bolt breakage, and achieve easy adjustment, easy chain tension, and improved stress conditions. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

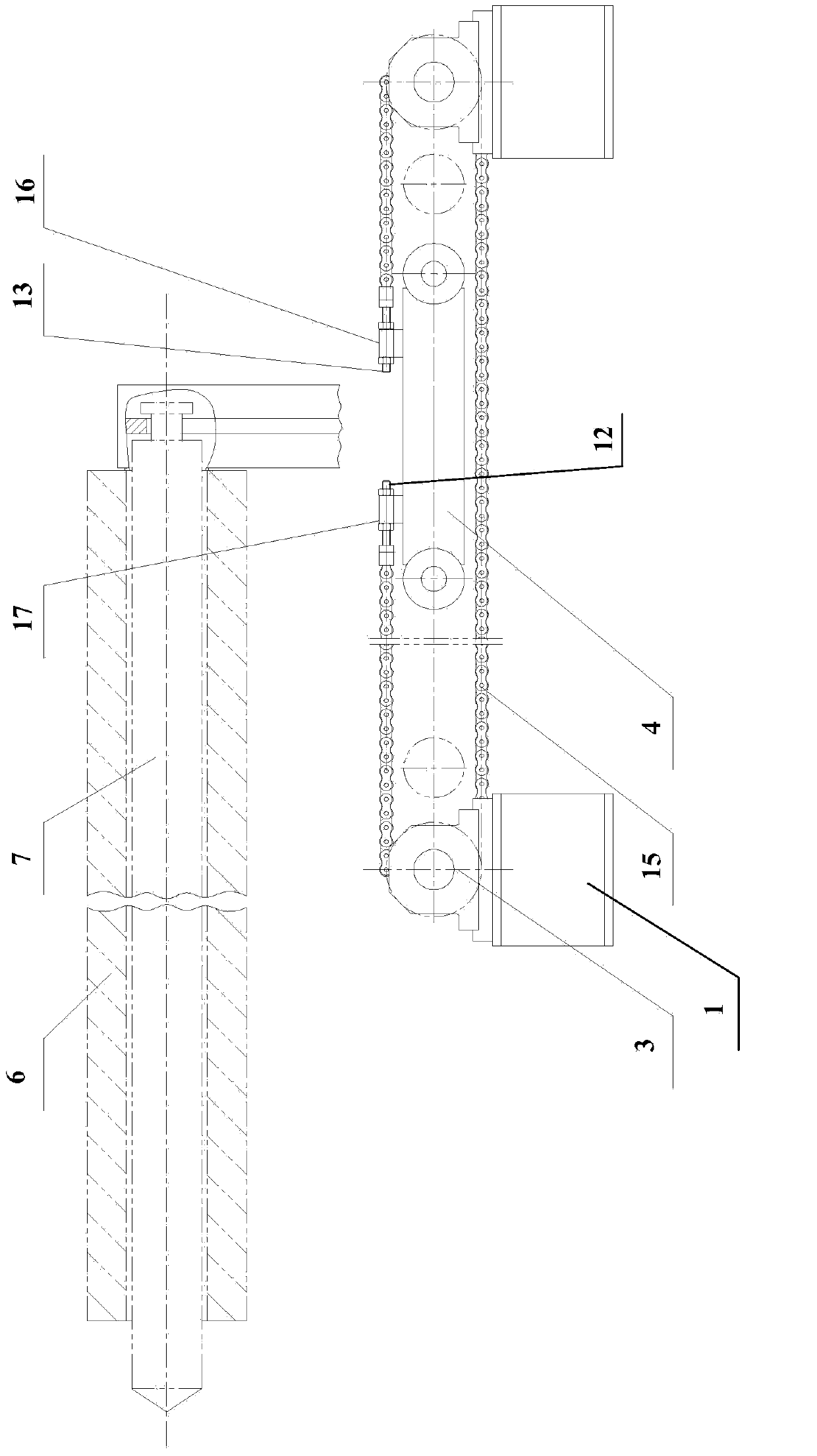

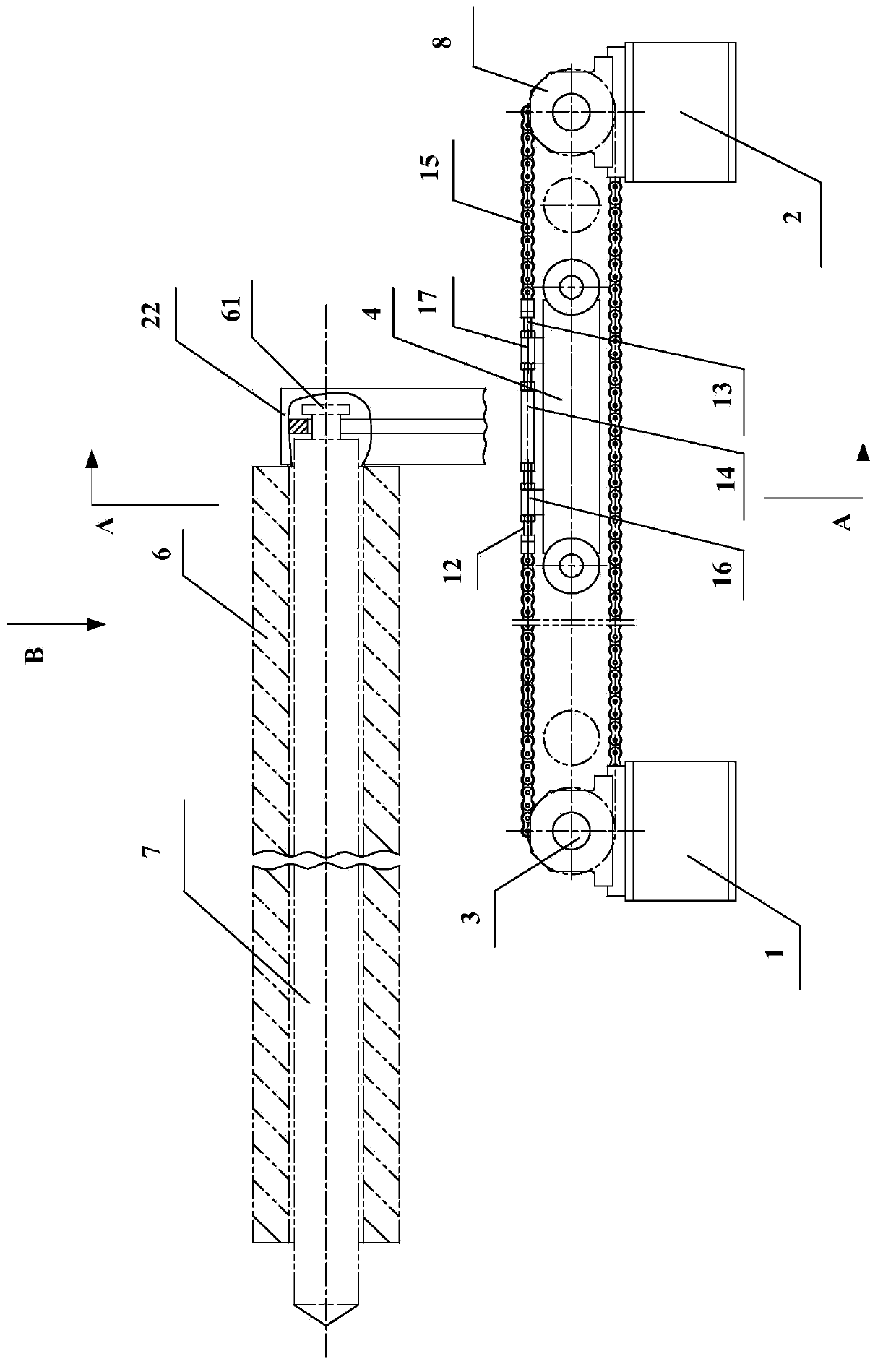

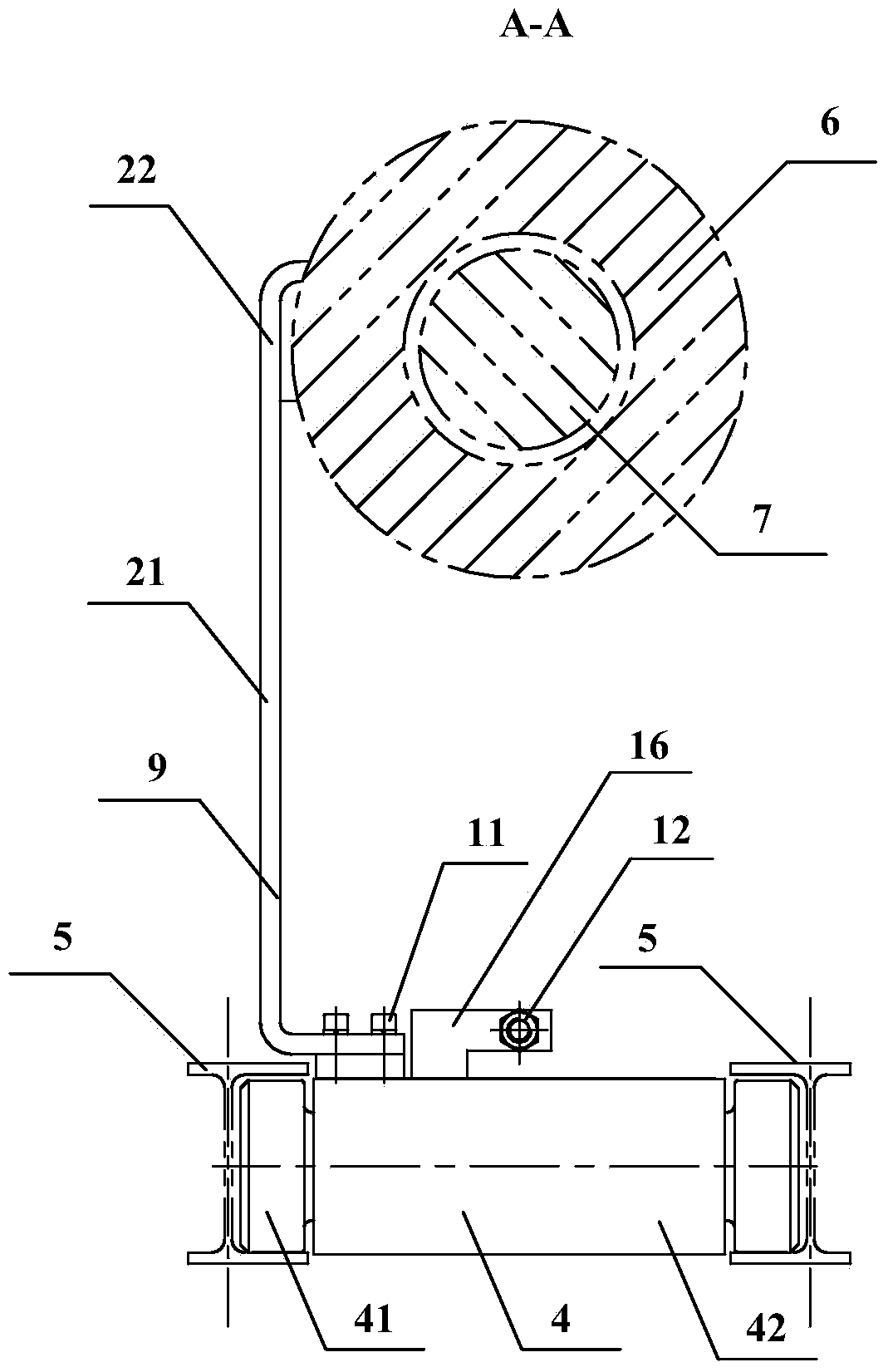

[0018] figure 2 Shown is the structural diagram of the cold-rolled pipe mill feeding mechanism of the present invention, image 3 shown as figure 2 The A-A line sectional schematic diagram, Figure 4 shown as figure 2 B direction view. refer to Figure 2-4 , The cold-rolled pipe mill feeding mechanism of the present invention comprises a chain 15, a push rod transport device 4, a track 5, a motor 1, a motor 2, a connecting rod 12, a connecting rod 13, a connecting device 14, a connecting block 17, a connecting block 16, Sprocket 3 and sprocket 8.

[0019] refer to Figure 2-4 , the push rod transport device 4 is arranged on the track 5 and moves along the track 5 . A connecting block 17 and a connecting block 16 are arranged on the push rod transportation device 4 , and both the connecting block 17 and the connecting block 16 are provided with through holes (not shown). The chain 15 is wound on the sprocket 3 and the sprocket 8 . The chain 15 is not closed but has ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com