Mask main body material and mask

A main material and mask technology, applied in the field of masks, can solve problems such as discomfort, face sticking, water vapor discharge, etc., to improve comfort and safety, and reduce the effect of water sticking on the face

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

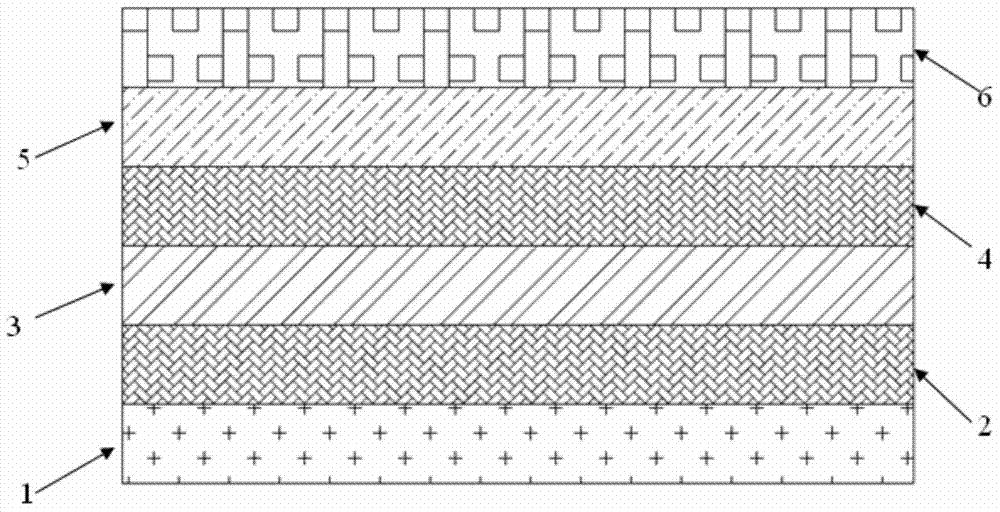

[0019] The main material of the mask in this example is composed of six layers of materials stacked in sequence, such as figure 1 Shown, hydrophilic spunbonded nonwoven fabric layer 1, first meltblown nonwoven fabric layer 2, wood pulp fiber layer 3, second meltblown nonwoven fabric layer 4, activated carbon fiber layer 5 and water repellent spunbonded nonwoven fabric layer Cloth layer 6, six layers of materials are ultrasonically bonded. Specifically, a polypropylene spunbond nonwoven fabric with a grammage of 8-15g / m2 is prepared by a spunbond method, and its surface is treated with hydrophilicity as a hydrophilic spunbond nonwoven layer; a grammage is prepared by a meltblown method 1-4g / m2 polypropylene melt-blown non-woven fabric, respectively as the first melt-blown non-woven fabric layer and the second melt-blown non-woven fabric layer; the grammage is 1-30g / m2 prepared by conventional weaving or non-woven methods The wood pulp fiber layer of m2; The activated carbon fi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Basis weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com