Automatic paper laying device for trays

An automatic, paper laying technology, applied in packaging, transportation and packaging, spreading thin soft materials, etc., can solve the problems of unguaranteed laying quality, low efficiency, etc., to avoid unreliable quality, avoid low efficiency, improve The effect of production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with the accompanying drawings.

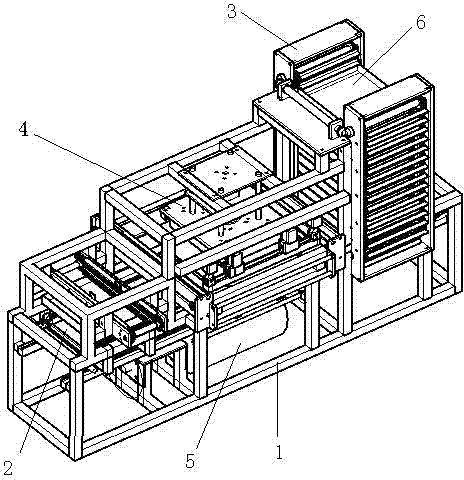

[0025] Such as Figure 1-Figure 6 As shown, a pallet automatic paper laying device includes a frame 1, a conveyor belt 2 is arranged on the frame 1, an automatic tray feeding frame 3 is provided at one end of the conveyor belt 2, and a An automatic paper laying device 4 , a sheet of paper 5 is arranged below the conveyor belt 2 at the automatic paper laying device 4 . The tray 6 is sent to the conveyor belt 2 at equal intervals through the automatic tray feeding rack (3). When the tray 6 reaches the automatic paper laying device 4, the automatic paper laying device 4 pulls out the sheet paper 5 and lays it on the tray 6. , and push it away to make it level, so that the sheet paper 5 is completely attached to the inner and outer walls of the tray 6.

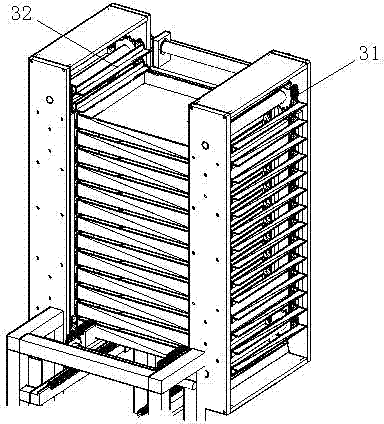

[0026] The tray automatic feeding frame 3 includes a transmission chain 31 arranged on both sides of the conveyor belt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com