Novel wagon hook body conveyor

A technology for railway wagons, conveyors, applied in the direction of conveyors, transportation and packaging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

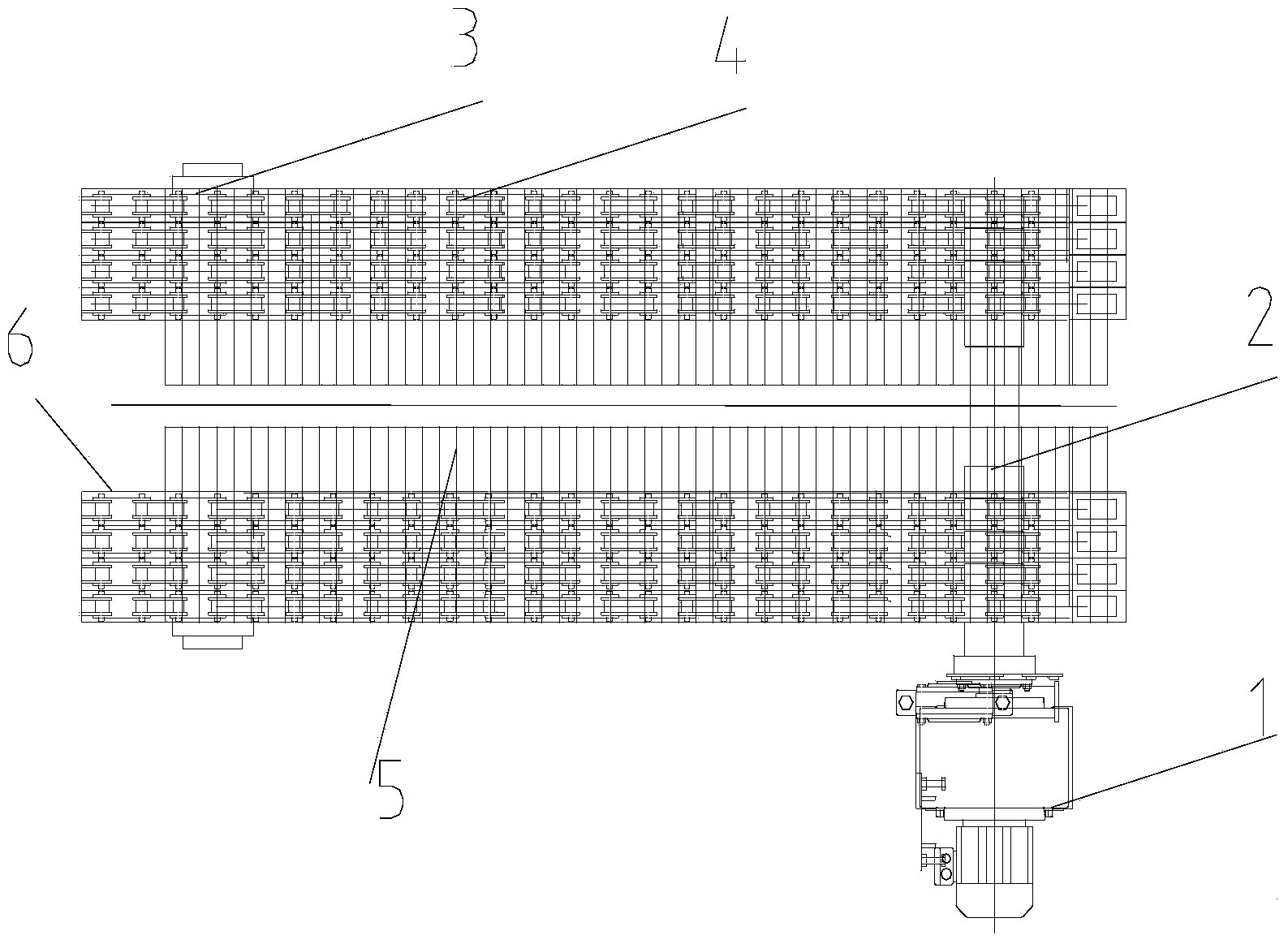

[0011] Embodiment 1 Composition of a railway wagon coupler coupler body conveyor and the functions of its components:

[0012] The invention relates to a new type of coupler body conveyor for railway freight cars. The coupler body conveyor includes: a motor reducer 1, a driving sprocket 2, a driven sprocket 3, a chain 4, a supporting chain row 5, and a frame 6. , which is characterized in that the coupler body conveyor drives the drive sprocket 2 to run through the motor reducer 1, so that the coupler body is conveyed along with the operation of the supporting chain row 5. The shafts of the driven sprocket 3 are semi-shaft and symmetrically distributed. Described chain 4 is four rows of roller chains. Described support chain row 5 is thick steel plate chain row.

Embodiment 2

[0013] Embodiment 2 The working process of a railway wagon coupler coupler body conveyor:

[0014] The motor reducer 1 drives the driving sprocket 2 to rotate, the driven sprocket 3 runs together with the driving sprocket 2 under the drive of the chain 4, the supporting chain row 5 is installed on the roller chain of the chain 4, and follows the chain to make a straight line and circular motion. The hook is placed in

[0015] Convey on the support chain row 5. The axle of described driven sprocket 3 is semi-shaft, and symmetrical distribution, it is convenient to knuckle element pin to pass through.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com