Rack roller overhauling fixture for rough mill

A technology for roughing mills and rack rolls, which is applied in the field of maintenance tooling for roughing mill rack rolls. It can solve the problems of inability to replace first and then overhaul, long maintenance shutdown time, and inconvenient on-site maintenance, etc., and achieve low implementation costs and reduce overall weight. , to avoid the effect of collision and interference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

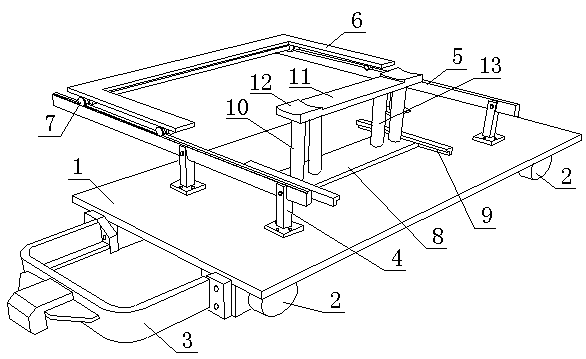

[0022] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0023] as follows figure 1 As shown, the roughing mill stand roll maintenance tooling includes

[0024] A push-pull trolley, the push-pull trolley includes a rectangular parallelepiped plate-shaped vehicle frame 1 and a wheel 2 positioned below the vehicle frame 1, and the wheel 2 matches the work roll change track of the roughing mill;

[0025] A roll change hook 3, the roll change hook 3 is a "U" shape with two joint ends, and the joint end of the roll change hook 3 is detachably connected to one end of the push-pull trolley frame 1 in the length direction through bolts;

[0026] The roller-changing track mechanism includes two rows of columns 4 arranged along the width direction of the vehicle frame, two in each row, and the two rows of columns are opposite along the length direction. The lower end of each column 4 has a boss for ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com