Patents

Literature

44results about How to "Smooth overhaul" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

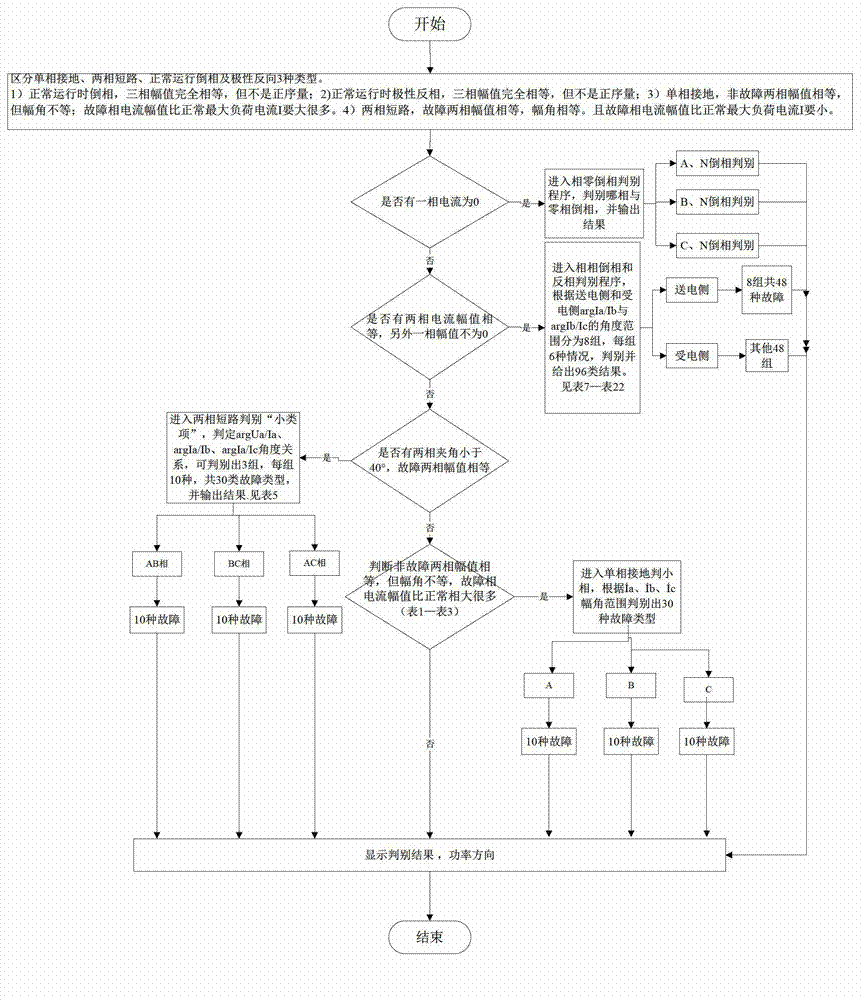

CT (Current Transformer) secondary circuit intelligent-detection method

ActiveCN103076529AReduce theoretical levelWork lessElectrical testingPhase sequence/synchronism indicationPhase currentsCurrent amplitude

The invention discloses a CT (Current Transformer) secondary circuit intelligent-detection method. The method comprises the following steps: 1) completing system initialization of a CT secondary circuit intelligent detector; 2) utilizing the CT secondary circuit intelligent detector to collect the phasor, the amplitude and the phase angle of current and voltage of a three-phase supply; 3) judging whether the phase current amplitude of one phase is zero or not; if yes, carrying out phase-zero phase-inversion judgment, namely judging which phase is inversed with a zero phase, and outputting corresponding results; and if not, entering a step 4); 4) judging whether the current amplitudes of two phases are same and meanwhile the amplitude of another phase is not zero; if not, entering a step 5); and if yes, carrying out phase-phase phase-inversion and polarity antiphase judgment, and then entering a step 7); 5) judging whether an inclined angle of two phases is less than 40 degrees and whether the amplitudes of two faulted phases are same; if yes, carrying out two-phase short-circuit judgment, judging which two phases are in short circuit, and then entering the step 7); and if not, entering a step 6); 6) judging whether the amplitudes of two non-faulted phases are same and the angles of amplitude are not same; if yes, carrying out single-phase grounding judgment, and then entering the step 7); if not, entering the step 7); and 7) displaying the judgment result and the power direction, and ending the detection.

Owner:STATE GRID CORP OF CHINA +1

Maintenance method for frame roller of roughing mill

ActiveCN102581021AAvoid collisions and interferenceEnsure safetyMetal rolling stand detailsMetal rolling arrangementsControl engineeringRolling mill

Owner:CHONGQING IRON & STEEL CO LTD

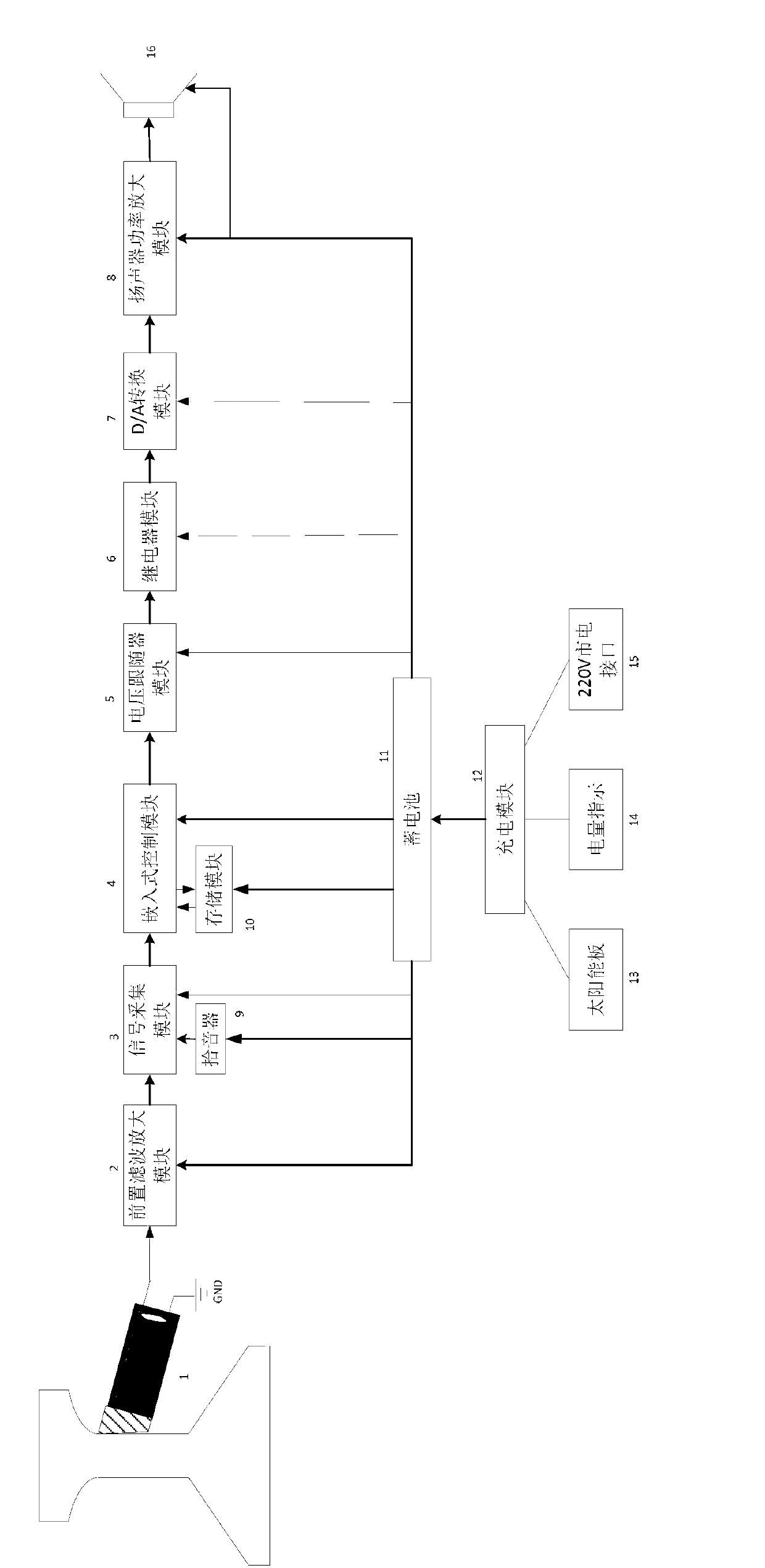

Portable approach alarm for electric traction train

InactiveCN103231729AReduce false alarm rateLow costRailway signalling and safetyElectricityTransmission channel

The invention relates to a portable approach alarm for an electric traction train. The approach alarm is applied to the field of safety protection and safety warning for approach of railway electric traction trains. The approach alarm is mainly composed of a sensor module 1, a pre-filtering amplification module 2, a signal acquisition module 3, an embedded control module 4, a voltage follower module 5, a relay module 6, a digital-to-analog conversion module 7, a loudspeaker power amplifying module 8, a pickup 9, a storage module 10, a storage battery 11, a charging module 12, a solar panel 13, a battery indicator 14, a 220V mains supply interface 15 and a loudspeaker 16. A beyond visual range sends warning information to remind constructors to leave lines timely to avoid the train when the train approaches, so that the smooth operation of railway line repair and the personal safety of constructors are guaranteed. According to the portable approach alarm for the electric traction train, an additional transmission channel is not required to be built; and the approach alarm is stable, reliable, low in false alarm rate, convenient to use, low in cost, small in limitation of environmental conditions and capable of being carried about by constructors.

Owner:郭立君

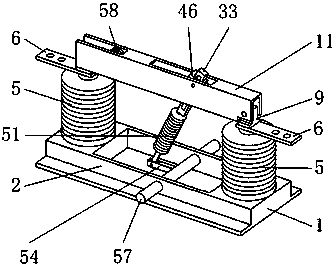

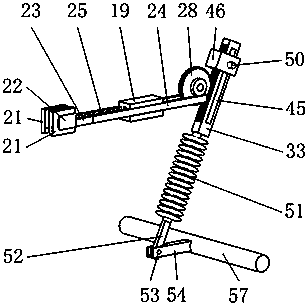

A high-reliability high-voltage isolation switch

PendingCN109192595AShorten maintenance timeAvoid dangerContact driving mechanismsAir-break switch detailsRepair timeInverted t

The invention belongs to the field of isolation switches and especially relates to a high-reliability high-voltage isolation switch. The switch comprises a base, a fixing notch, a first transmission groove, a first insulating porcelain post, an inverted T-shaped contact and a conductive contact rod, wherein two opposite side end faces of the base are respectively provided with a fixing notch. Theupper end face of the base is provided with a first transmission groove. When it is necessary to disconnect the high-voltage disconnector in cable maintenance, serious corrosion may occur between theinverted T-shaped contact and the sliding contact plate of the disconnector, which makes the disconnection of the high-voltage disconnector difficult. A transmission the acts on a cable pole by a serviceman, a sliding contact plate slides slightly along a first trapezoidal sliding groove on the conductive contact rod under the action of a transmission device on the cable rod. The inverted T-shapedcontact is loosened and the corrosion is released, and then the high-voltage disconnector is easily turned off, so that the cable inspection and repair is carried out smoothly, the cable inspection and repair time is saved, and the danger caused by the failure of the disconnector is avoided.

Owner:秦锦峰

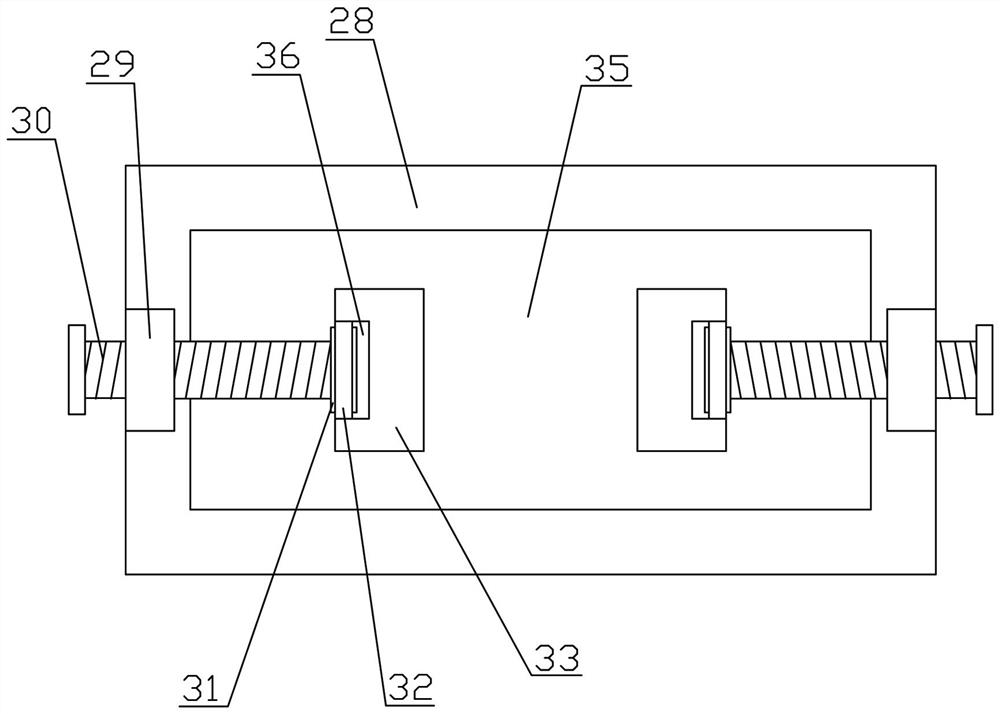

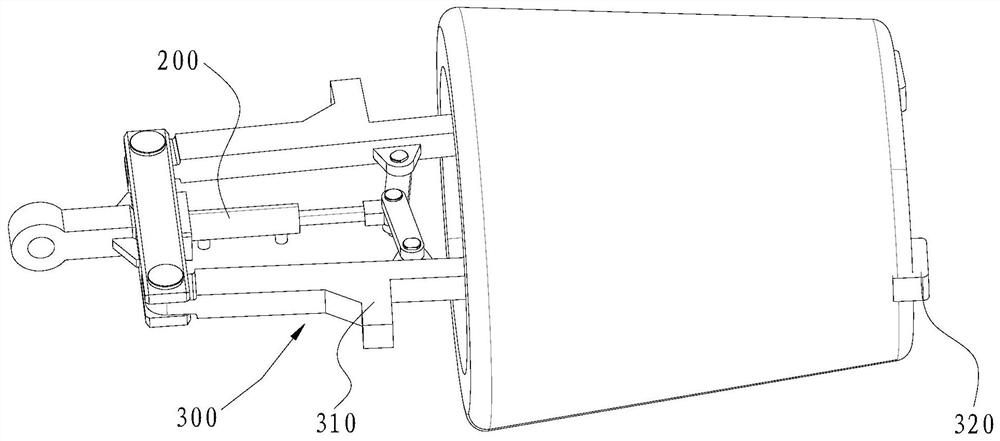

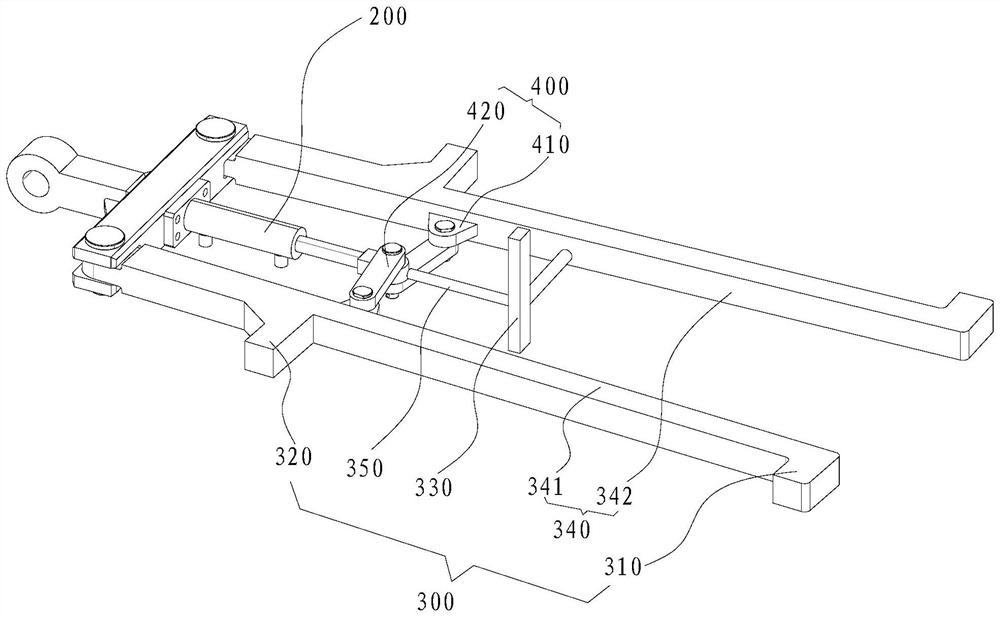

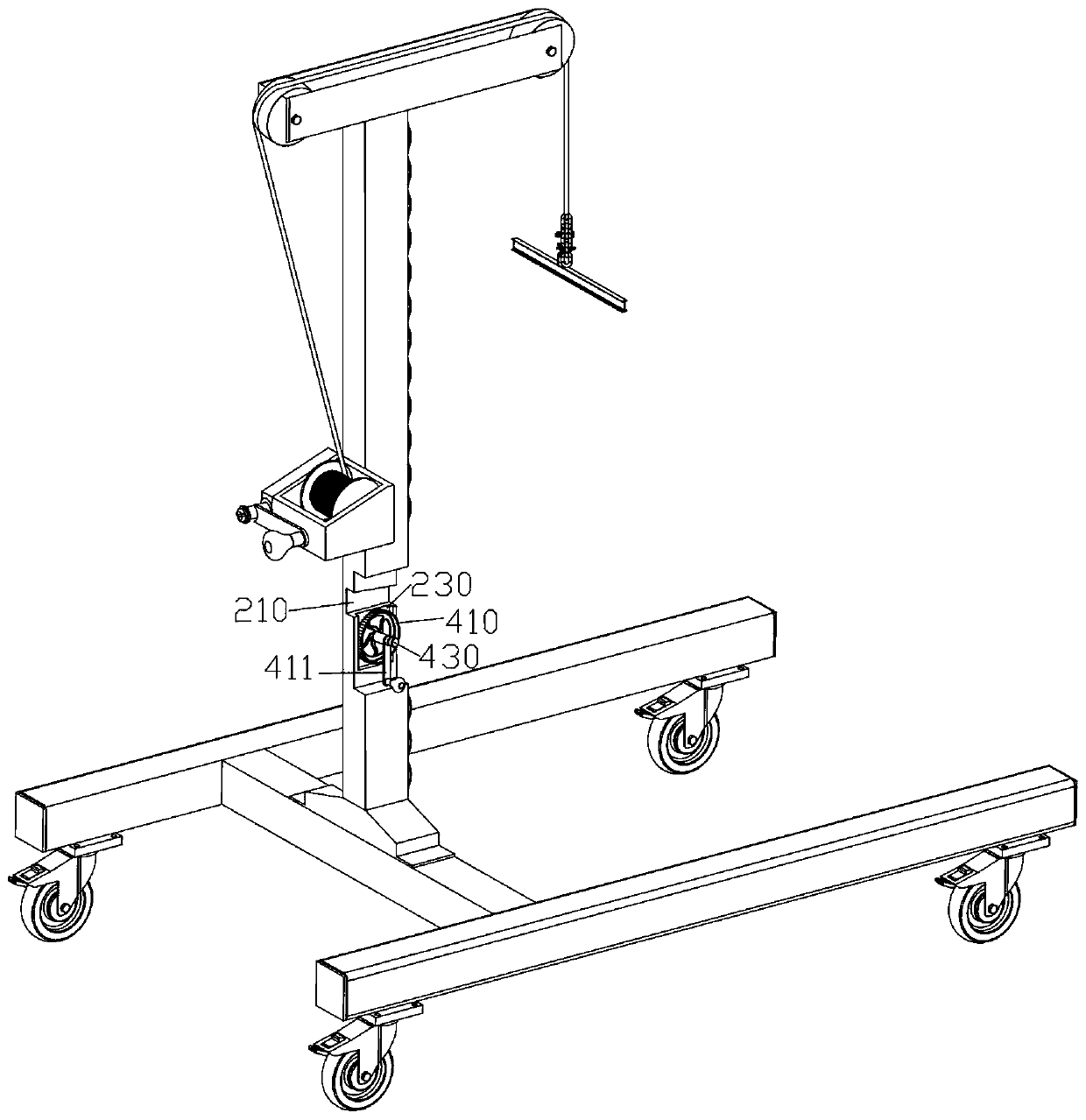

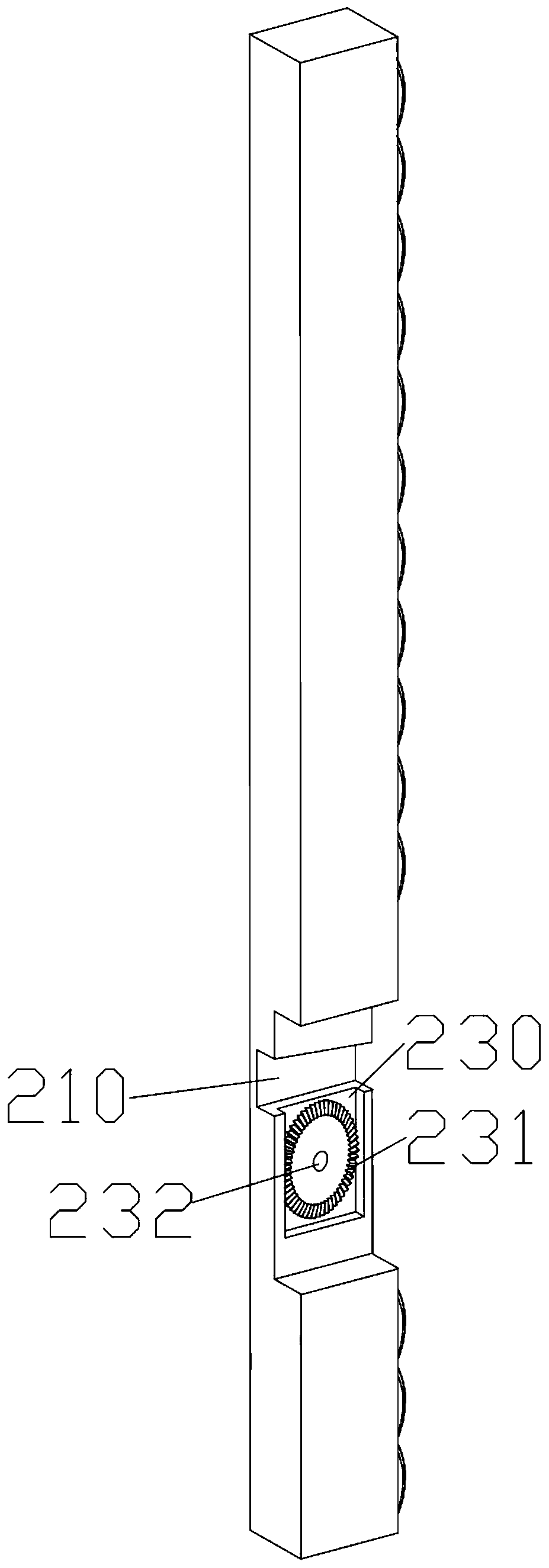

Disassembly and assembly device

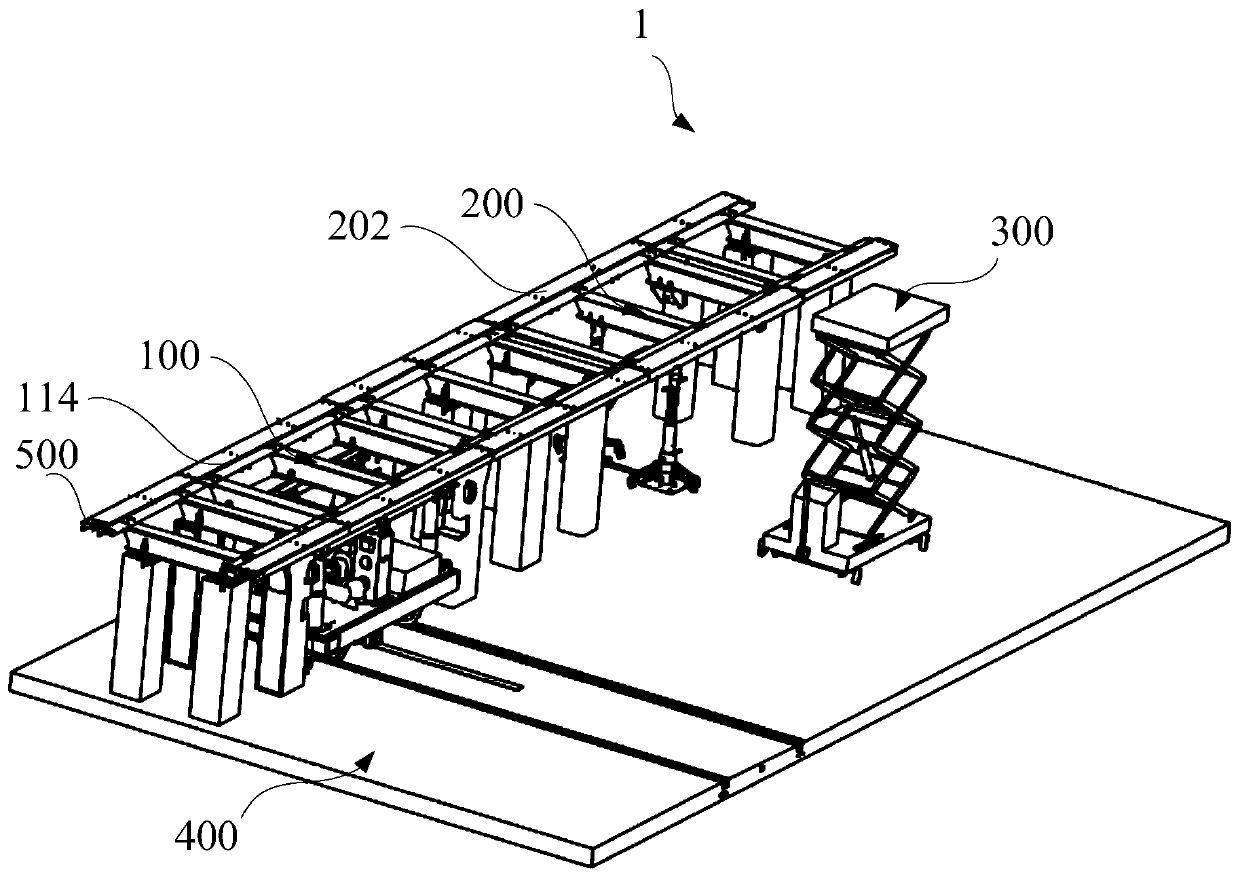

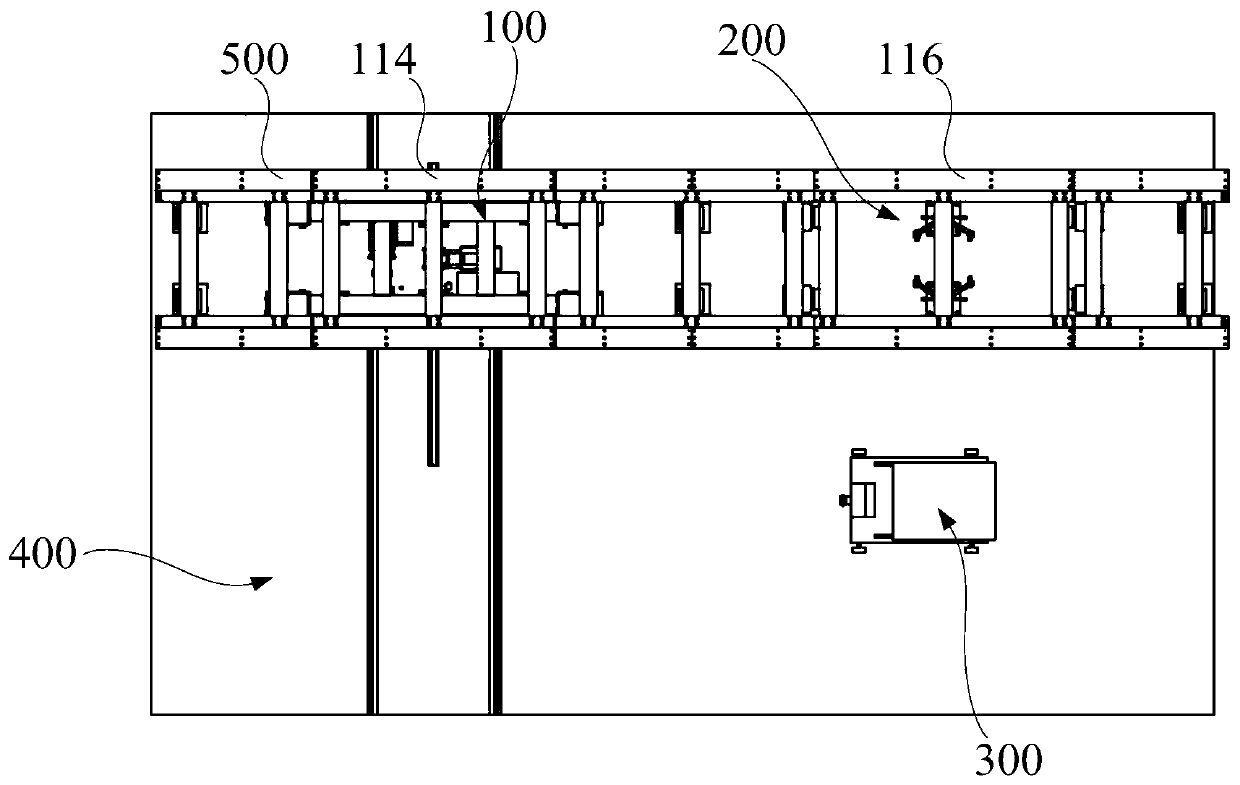

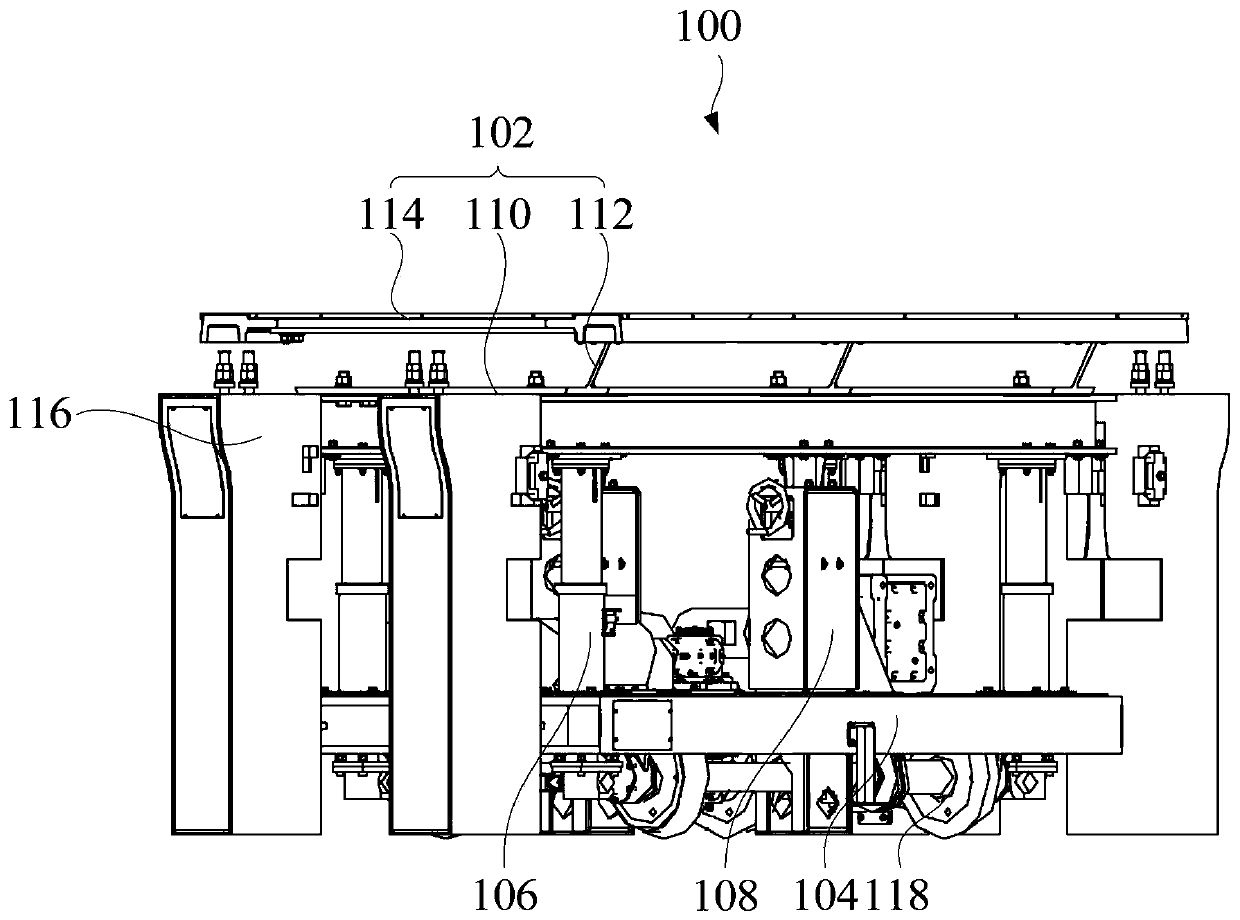

InactiveCN111451979AMeet the needs of different structuresAvoid the problem of extrusion deformation that brings difficulties to maintenanceLifting framesWork benchesStructural engineeringMechanical engineering

The invention provides a disassembly and assembly device. The disassembly and assembly device comprises a first disassembly and assembly assembly, the first disassembly and assembly assembly comprisesa first supporting table, a first support, a first lifting device, and a second lifting device, the first support is mounted below the first supporting table, the first lifting device is connected with the first supporting table and the first support, and is configured to adjust the distance between the first supporting table and the first support, the second lifting device is mounted on one ofthe first supporting table and the first support, is located between the first supporting table and the first support and is configured to be suitable for being in abut joint with the other one in thefirst supporting table and the first support, the first lifting device is mounted on the edge of the first supporting table, the second lifting device is mounted in the middle of the first supportingtable or is configured to be suitable for being in abut joint with the middle of the first supporting table, according to the disassembly and assembly device, through the second lifting device, supporting of the middle of the first supporting table is achieved, and the first supporting table is uniform in stress and is not prone to deforming under the stress condition.

Owner:CHINA RAILWAY CONSTR HEAVY IND

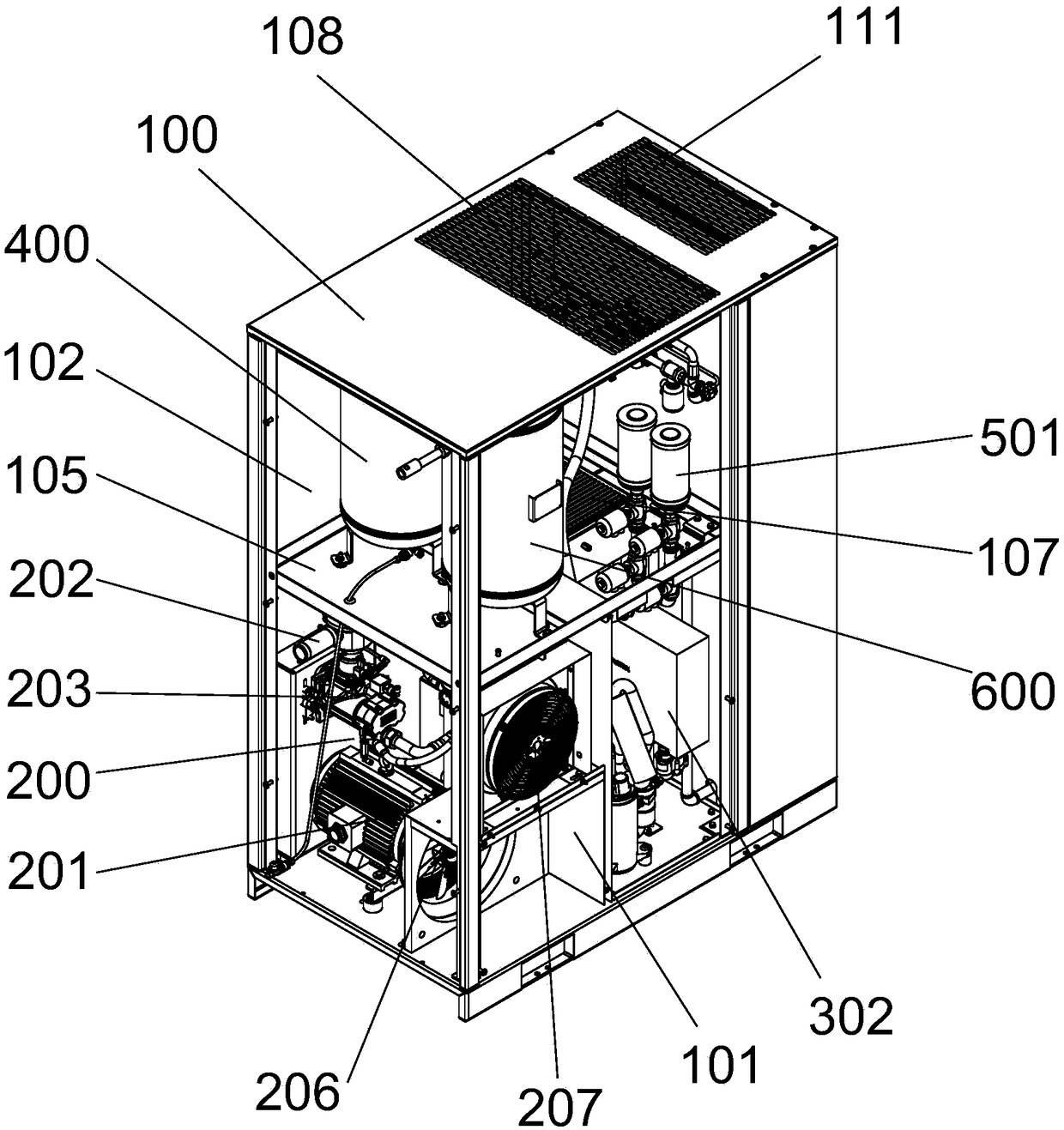

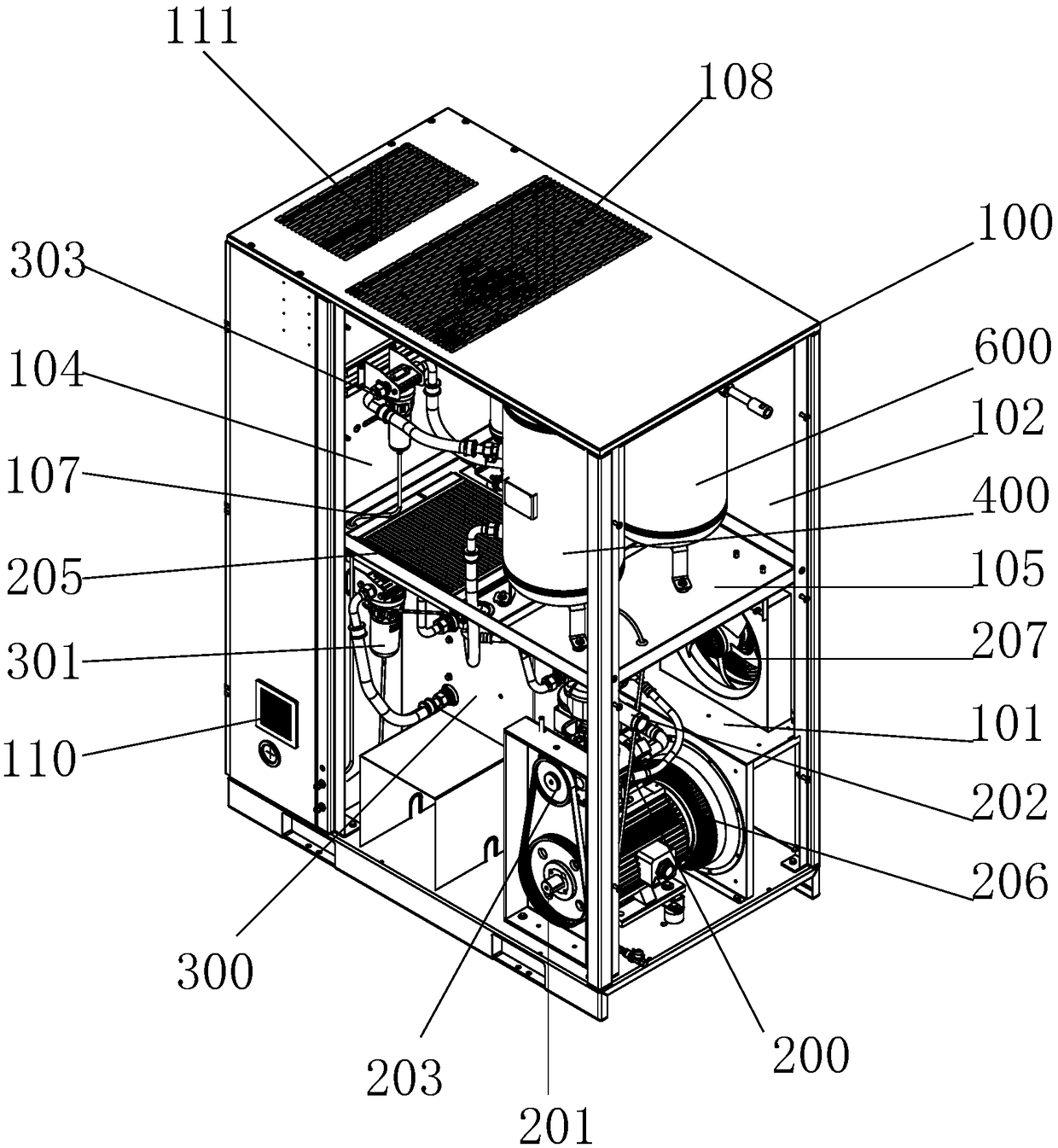

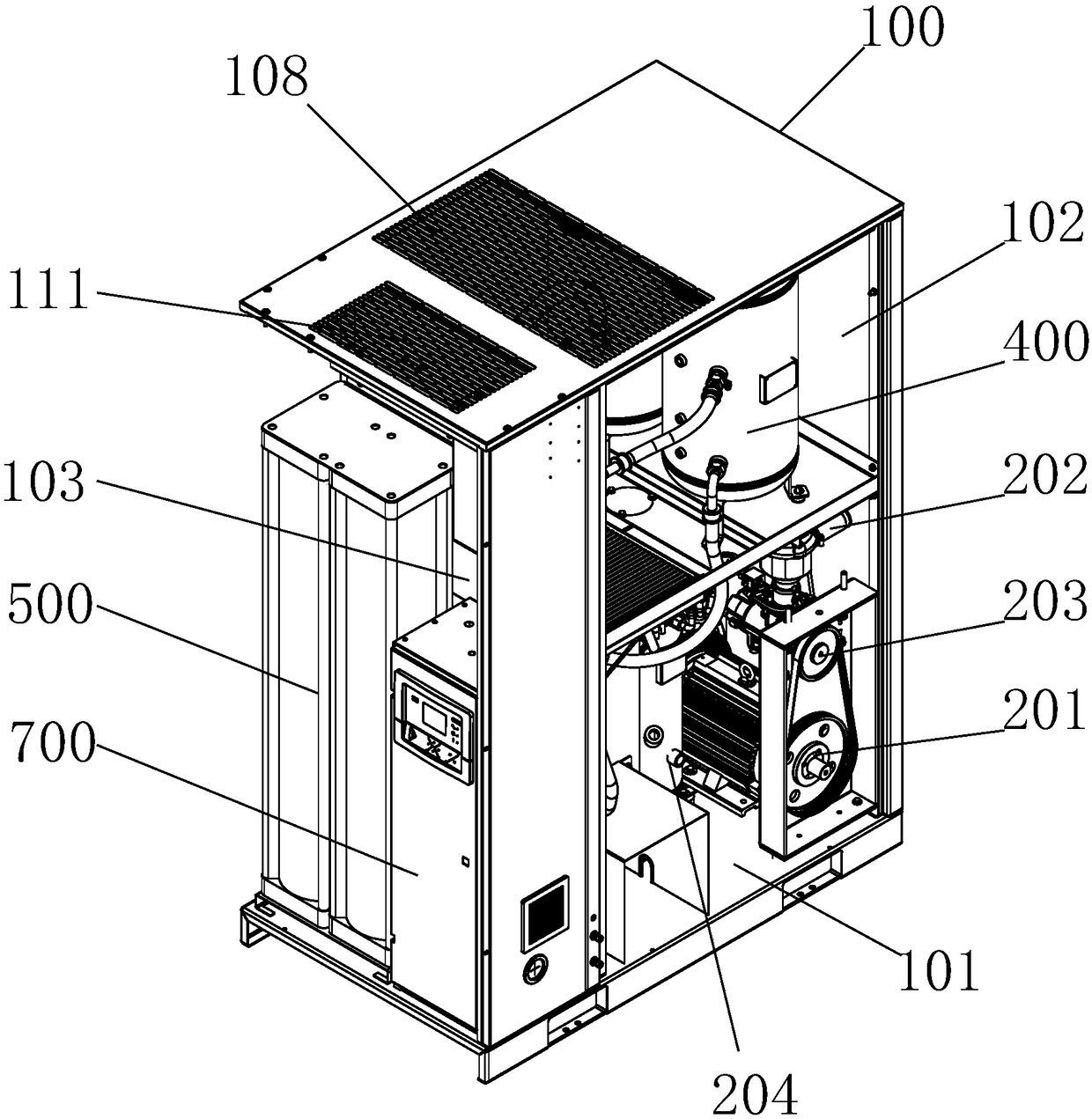

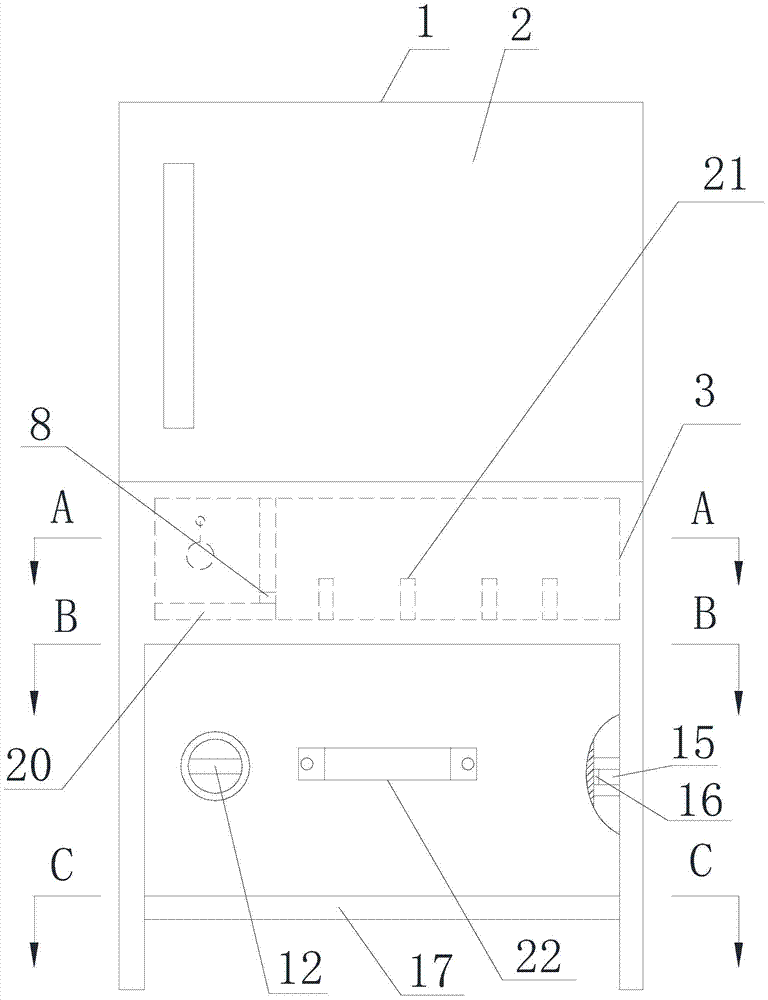

Oxygenation device

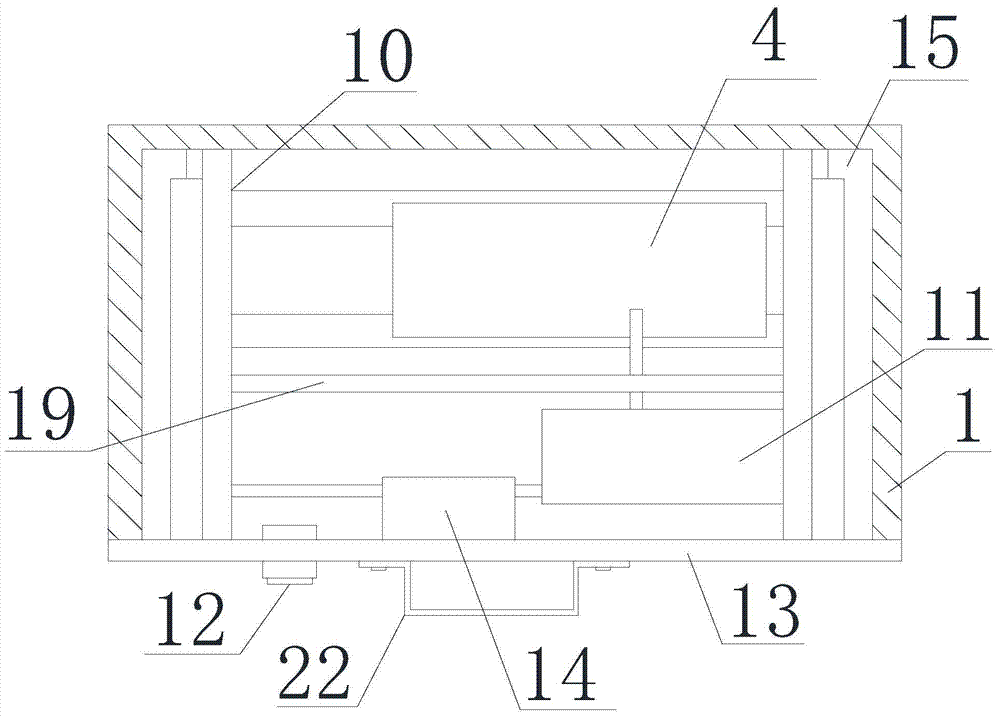

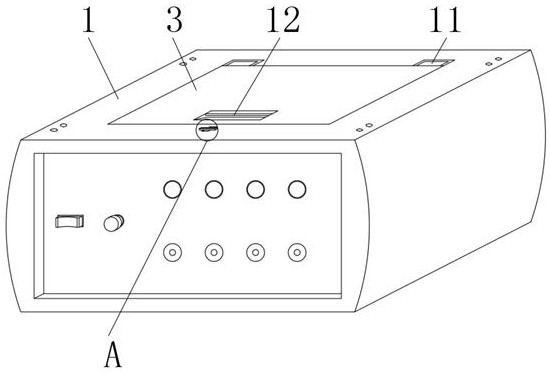

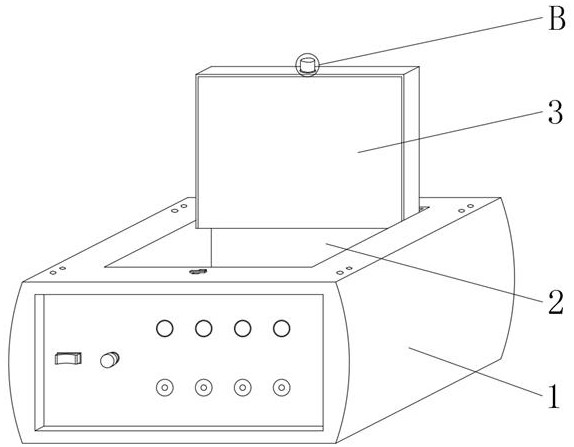

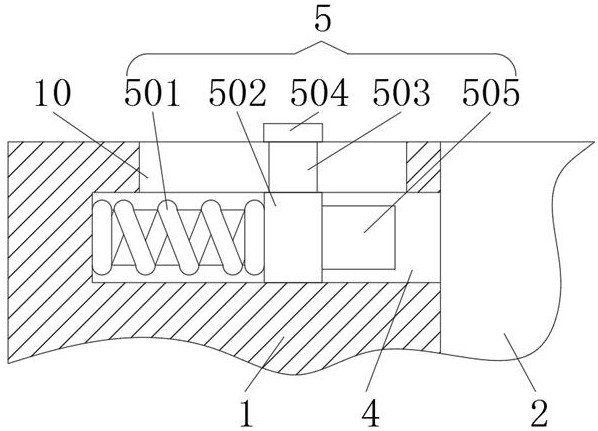

PendingCN108862203ALower center of gravityImprove stabilitySpecific gas purification/separationOxygen preparationMolecular sieveAir compression

The invention discloses an oxygenation device. The oxygenation device comprises a machine box, an air compression unit, an air treatment unit, a molecular sieve adsorption tower, an oxygen storage device and a controller, wherein the air compression unit, the air pretreatment unit, the molecular sieve absorption tower and the oxygen storage device are sequentially connected; the controller is usedfor controlling the air compression unit, the air pretreatment unit, the molecular sieve absorption tower and the oxygen storage device; a first installation chamber and a second installation chamberare arranged in the machine box, the first installation chamber is positioned at the bottom part, and the second installation chamber is positioned at the top part; the air compression unit is arranged in the first installation chamber; the oxygen storage device is arranged in the second installation chamber. The oxygenation device has the advantages that the structure is compact, the layout is reasonable, and the center of gravity is lower; the stability is higher, and the stability can be maintained in the transportation process; the overhauling and maintenance are convenient, and the use cost is lower.

Owner:ATLAS COPCO WUXI COMPRESSOR

Combined support for electrical equipment maintenance

ActiveCN113097911AEasy installation and disassemblyEasy to passLifting devicesWork benchesRotational axisElectric power equipment

The invention belongs to the technical field of electric power overhaul, and particularly relates to a combined support for electric power equipment overhaul. The combined support comprises a base, a rotating mechanism, two groups of lifting mechanisms, an overhaul platform, an operation table, a telescopic ladder stand and a controller; first supporting legs are arranged below the base, and first rollers are arranged at the bottoms of the first supporting legs. the operation table comprises a support, an operation groove formed in the center of the support, fixing blocks arranged at the two ends of the support, a rotating shaft rotationally connected to the fixing blocks, a clamping plate rotationally connected to the tail end of the rotating shaft, a supporting plate arranged at the lower end of the clamping plate and a plurality of second rolling wheels arranged below the supporting plate, and the rotating shaft penetrates through the clamping plate; and limiting pieces are arranged on the rotating shaft and located on the two sides of the clamping plate. According to the combined support, electrical equipment of different sizes can be stably fixed, maintenance is convenient, any height adjustment and angle adjustment are achieved, meanwhile, operators can conveniently get on and off the support at any time, maintenance tools can be conveniently transferred at any time, and the working efficiency of the maintenance operators is greatly improved.

Owner:国网河南省电力公司方城县供电公司

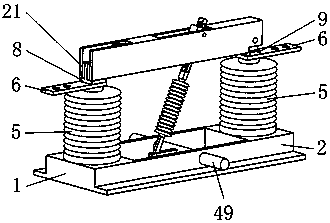

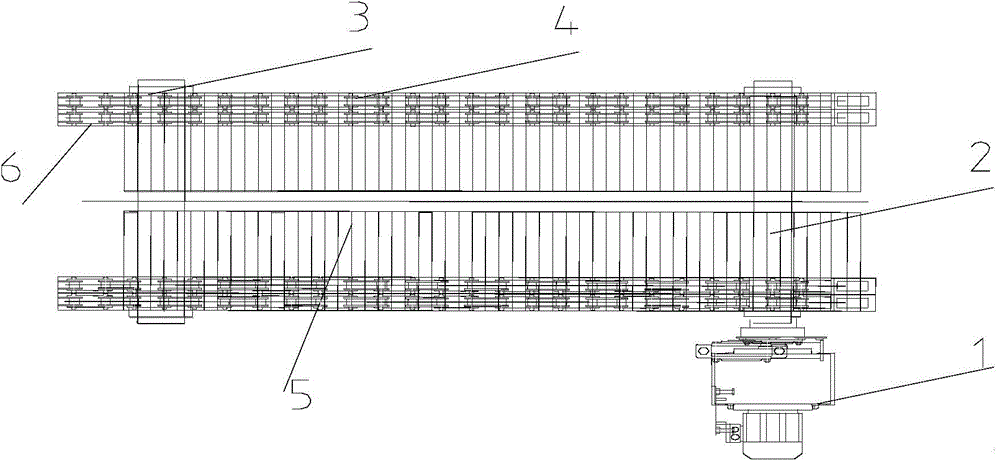

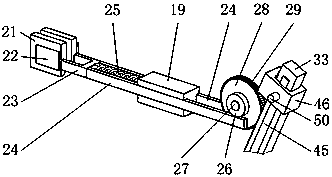

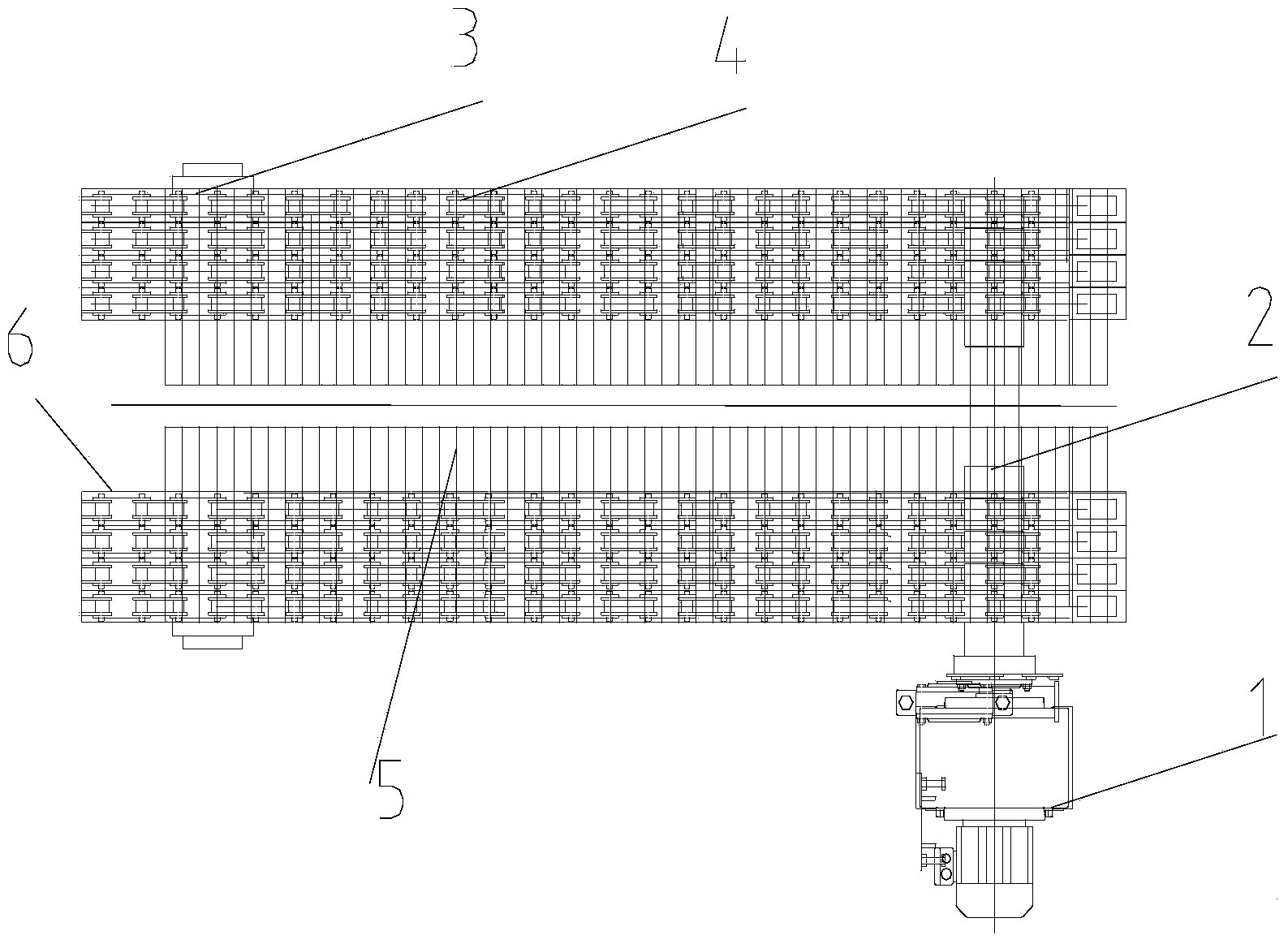

Novel car coupler tail frame conveyor for a wagon

The invention relates to a novel car coupler tail frame conveyor for a wagon. The novel car coupler tail frame conveyor for the wagon comprises a motor reducing gear 1, a driving chain wheel 2, a driven chain wheel 3, a chain 4, a supporting chain row 5 and a frame 6, and is characterized in that the car coupler tail frame conveyor drives the driving chain wheel 2 to run through the motor reducing gear 1, so as to enable a car coupler tail frame to convey with the running of the supporting chain row 5. The novel car coupler tail frame conveyor provided by the invention has the advantages as follows: the conveying of the car coupler tail frame is enabled to achieve automatic flow line production.

Owner:NINGXIA ZHONGYUAN TIANSHENG TECH

A stable high voltage disconnector

PendingCN109192596AShorten maintenance timeAvoid dangerContact driving mechanismsAir-break switch detailsRepair timeEngineering

The invention belongs to the field of disconnector, in particular to a stable high-voltage disconnector, which comprises a base, a fixing notch, a first transmission groove, a first insulating ceramicpost, an inverted T-shaped contact, a second straight rack, a third straight rack, a fourth straight rack and the like, wherein two opposite side end faces of the base are respectively provided witha fixing notch. The upper end face of the base is provided with a first transmission groove; When it is necessary to disconnect the high voltage disconnector for cable maintenance, serious corrosion may occur between the inverted T-shaped contact and the sliding contact plate of the disconnector. A transmission the acts on a cable pole by a serviceman, a sliding contact plate slides slightly alonga first trapezoidal sliding groove on the conductive contact rod under the action of a transmission device on the cable rod. The inverted T-shaped contact is loosened and the corrosion is released, and then the high-voltage disconnector is easily turned off, so that the cable inspection and repair is carried out smoothly, the cable inspection and repair time is saved, and the danger caused by thefailure of the disconnector is avoided.

Owner:夏建明

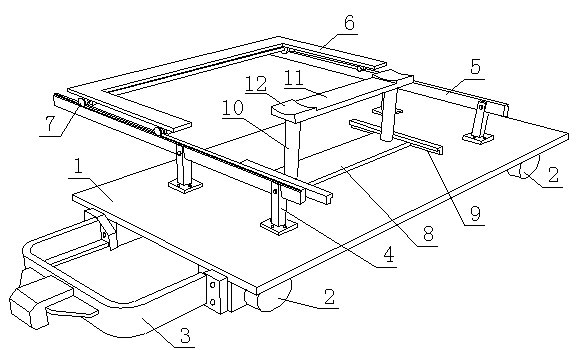

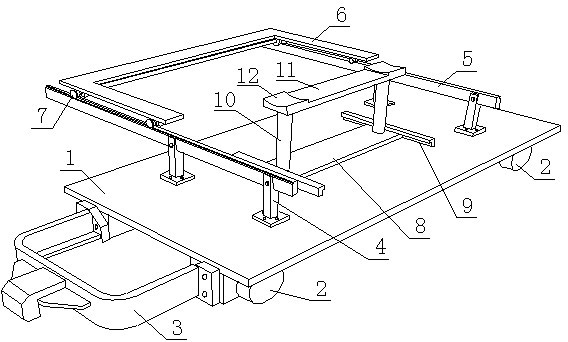

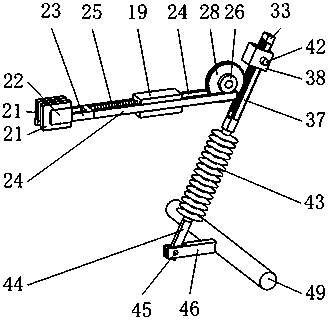

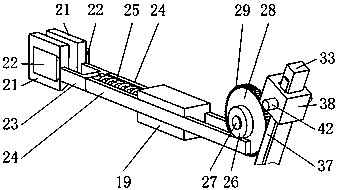

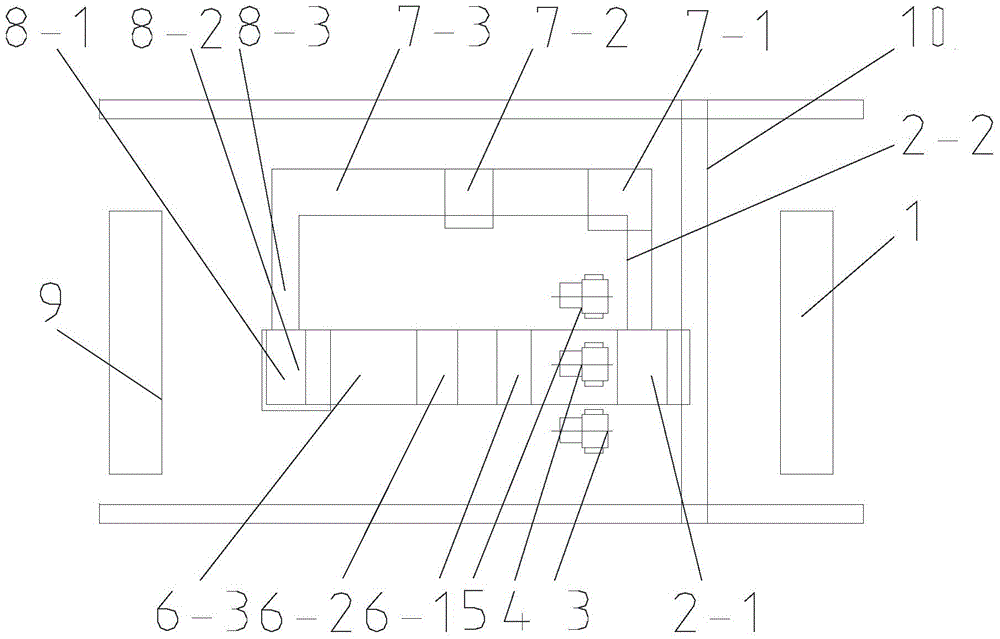

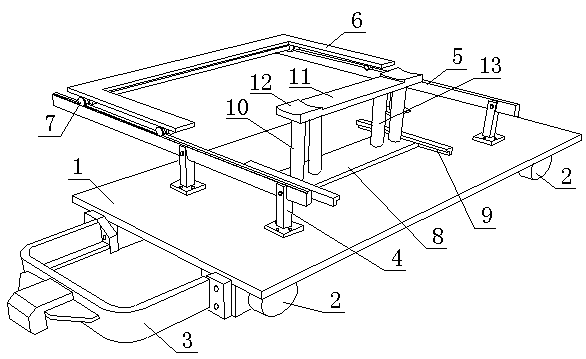

Rail wagon coupler overhauling conveying line

InactiveCN104554336ASmooth overhaulRailway auxillary equipmentMechanical conveyorsStructural engineeringTruck

The invention relates to a novel rail wagon coupler overhauling conveying line. The conveying line comprises a to-be-overhauled whole-set coupler storage rack 1, a coupler disassembling platform 2, a coupler knuckle lock conveying cart 3, a coupler knuckle conveying cart 4, a coupler pusher conveying cart 5, a coupler yoke overhauling conveying line 6, a coupler body overhauling conveying line 7, a coupler complete-set assembly test bed 8, an assembled complete-set coupler storage rack 9 and a crown block 10. The rail wagon coupler overhauling conveying line is characterized in that the coupler yoke overhauling conveying line 6 and the coupler body overhauling conveying line 7 respectively convey disassembled components of couplers to component conveying lines to be overhauled, and then the components are assembled in complete sets. The rail wagon coupler overhauling conveying line has the main advantages that automatic line production is formed for overhauling of the main components; and time for overhauling is shortened.

Owner:NINGXIA ZHONGYUAN TIANSHENG TECH

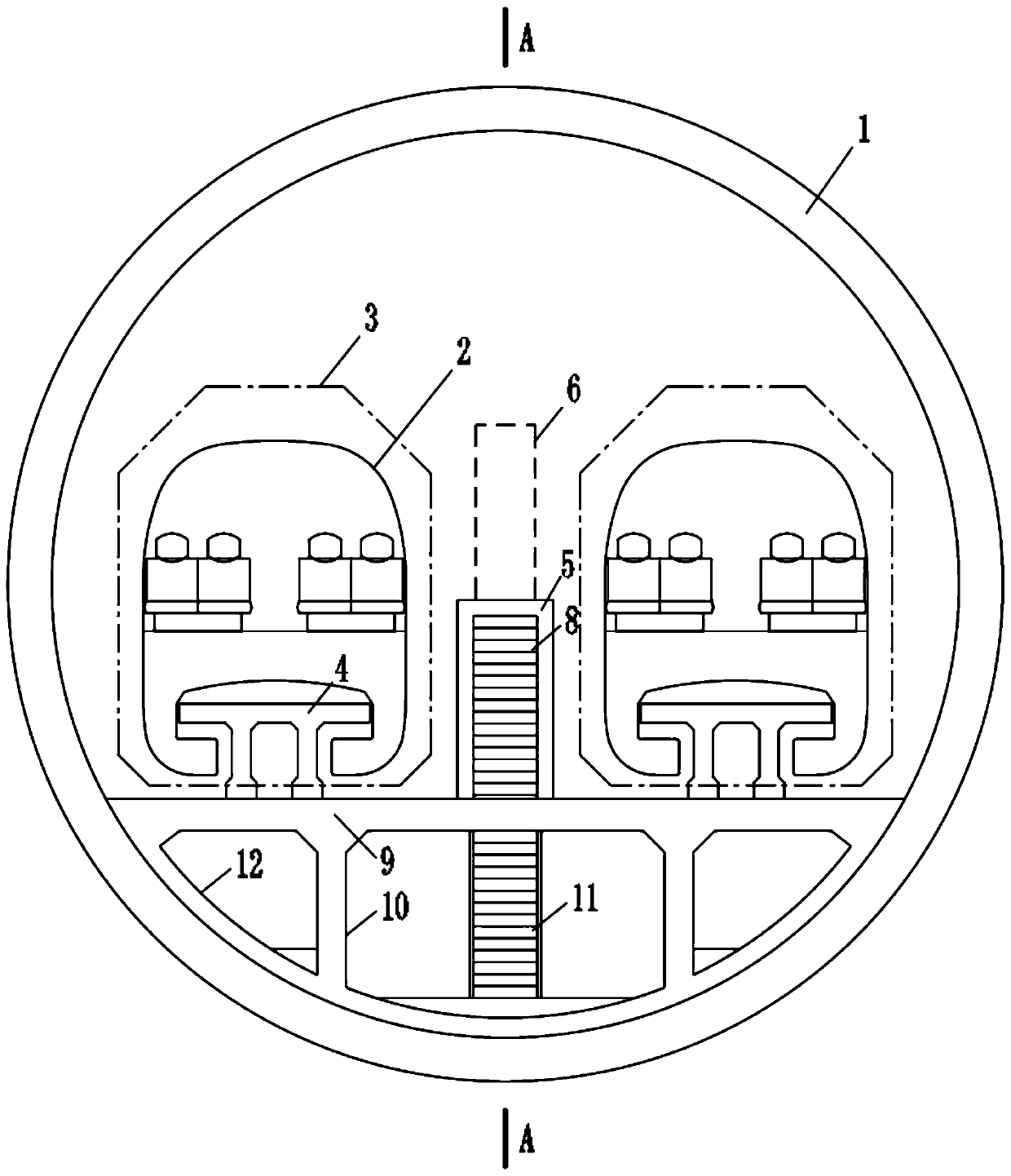

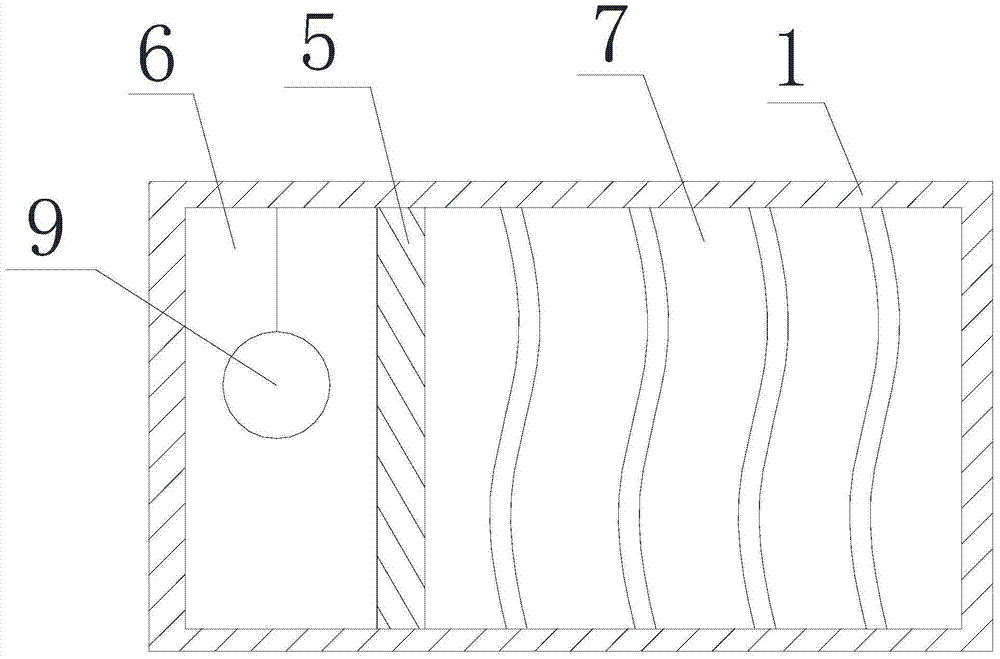

Internal structure of maglev vacuum pipeline

PendingCN110920640AReduce construction costsPerfect evacuation and maintenance functionRailway tunnelsSliding/levitation railway systemsUltra high speedDouble tube

The invention discloses an internal structure of a maglev vacuum pipeline. A through under-rail structure is arranged at the inner bottom of the pipeline body structure in the length direction of thepipeline body structure, an inter-rail channel and maglev rails located on the two sides of the inter-rail channel are arranged at the top of the under-rail structure, an ultra-high-speed maglev traincan run on the maglev rails in a two-way mode, and the operation space of the maglev rails is a vacuum environment. The inter-rail channel is of a closed structure and is arranged in a penetrating mode along the pipeline body structure, the upper portion of the inter-rail channel is provided with a platform safety space meeting the train driving requirement, the inter-rail channel can enter the inter-rail channel through the inter-rail channel stairs and the inter-rail channel doors to the top face of the under-rail structure, and the inter-rail channel side wall doors are arranged on the twoside walls of the inter-rail channel according to requirements. Space requirements of a train form, evacuation or maintenance and equipment arrangement are comprehensively planned through the internal structure of the pipeline, the section space of the pipeline is effectively utilized, the pipeline is suitable for a single-pipe double-line form, compared with a double-pipe single-line form, the construction cost is reduced, the evacuation and maintenance functions are perfected, and the equipment space is reasonably configured.

Owner:CHINA RAILWAY DESIGN GRP CO LTD

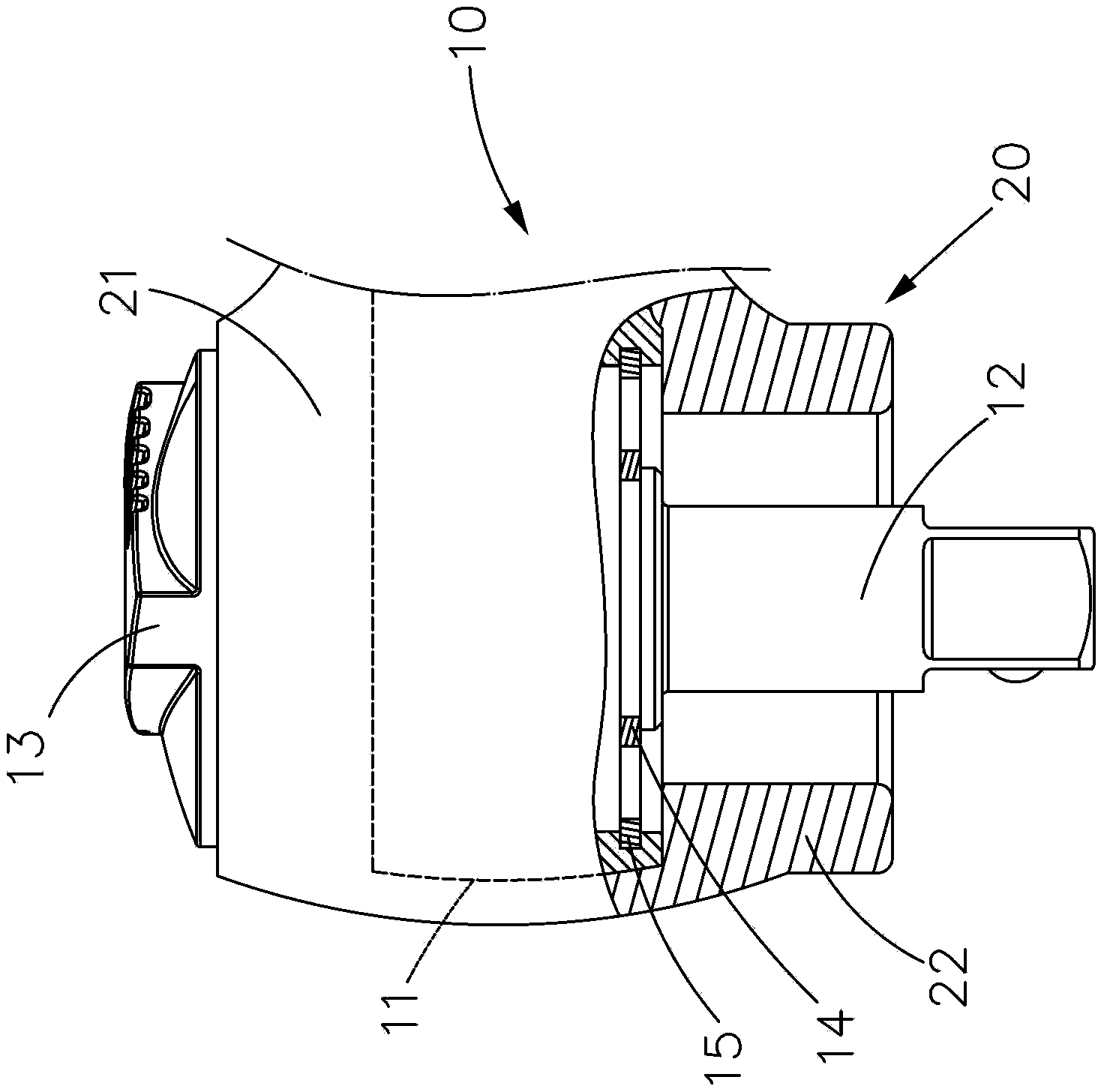

Insulation structure of wrench

InactiveCN103381581APrevent unauthorized entryPrevent leakageSpannersWrenchesInsulation layerEngineering

The invention relates to an insulation structure of wrench, specifically to an insulation structure of wrench with good protection effect. A wrench head of the wrench comprises a shell body; an insertion part is exposed on the outside of the shell body; an insulation layer comprises an insulation shell and an insulation sleeve part; while the insulation shell covers the outer surface of the shell body, the insulation sleeve part integrated with the insulation shell surrounds the insertion part; the insulation sleeve part is combined with an insulation loop; a combining section extends from the insulation loop along the inner wall of the insulation sleeve part; the insulation loop is provided with a connecting seal edge at the inner end of the combining section, the connecting seal edge converging towards the insertion part; and an insulation bush extends outward from the inner edge of the connecting seal edge in the axial direction of the outer wall of the insertion part. The insulation sleeve part is combined with the insulation loop, the insulation loop can be detached according to requirements for maintenance of the head of the insulation wrench and an insulation effect for preventing electric leakage is achieved.

Owner:MATATAKITOYO TOOL

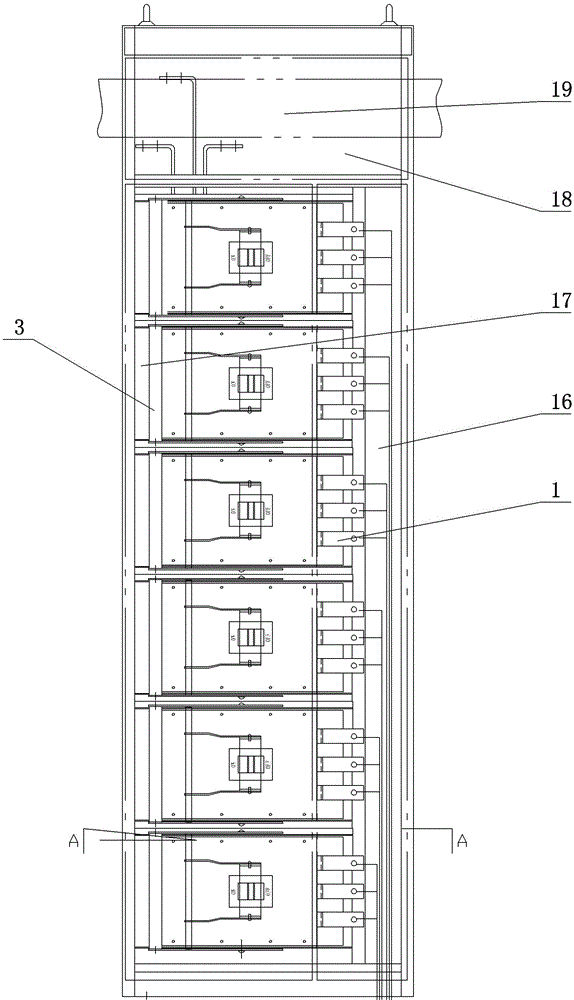

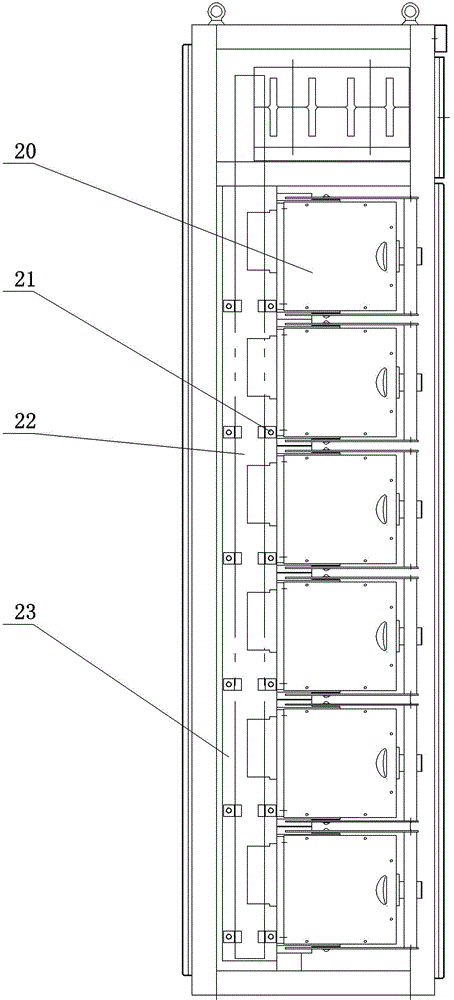

Combined low voltage control switchgear

InactiveCN104184055BFirmly connectedSmooth disengagementBus-bar/wiring layoutsSubstation/switching arrangement casingsLow voltageBusbar

A combined low-voltage control switchgear belongs to the technical field of low-voltage control switchgear, and in particular relates to a combined low-voltage control switchgear. The invention provides a combined low-voltage control switch cabinet with safe use, convenient operation and convenient maintenance. The present invention adopts the following technical scheme. The present invention includes a cabinet body. The upper end of the cabinet body is the main busbar room, the front part of the cabinet body is the switch room, the side part of the cabinet body is the cable room, and the rear part of the cabinet body is the auxiliary busbar room. The vertical auxiliary busbars in the busbar room are connected to the horizontal main busbars in the main busbar room; the switch room includes multiple switch chambers arranged vertically, each switch chamber includes a fixed bracket box, and the front side of the fixed bracket box is a movable The fixed bracket box is fixed with a vertical busbar with a plug at the front end, the vertical busbar is connected to the auxiliary busbar, and the plug corresponding to the vertical busbar on the movable bracket box is provided with a plug chuck. The clip is connected to the input terminal of the circuit breaker through the inner drain bar.

Owner:沈阳天维电气设备制造有限公司

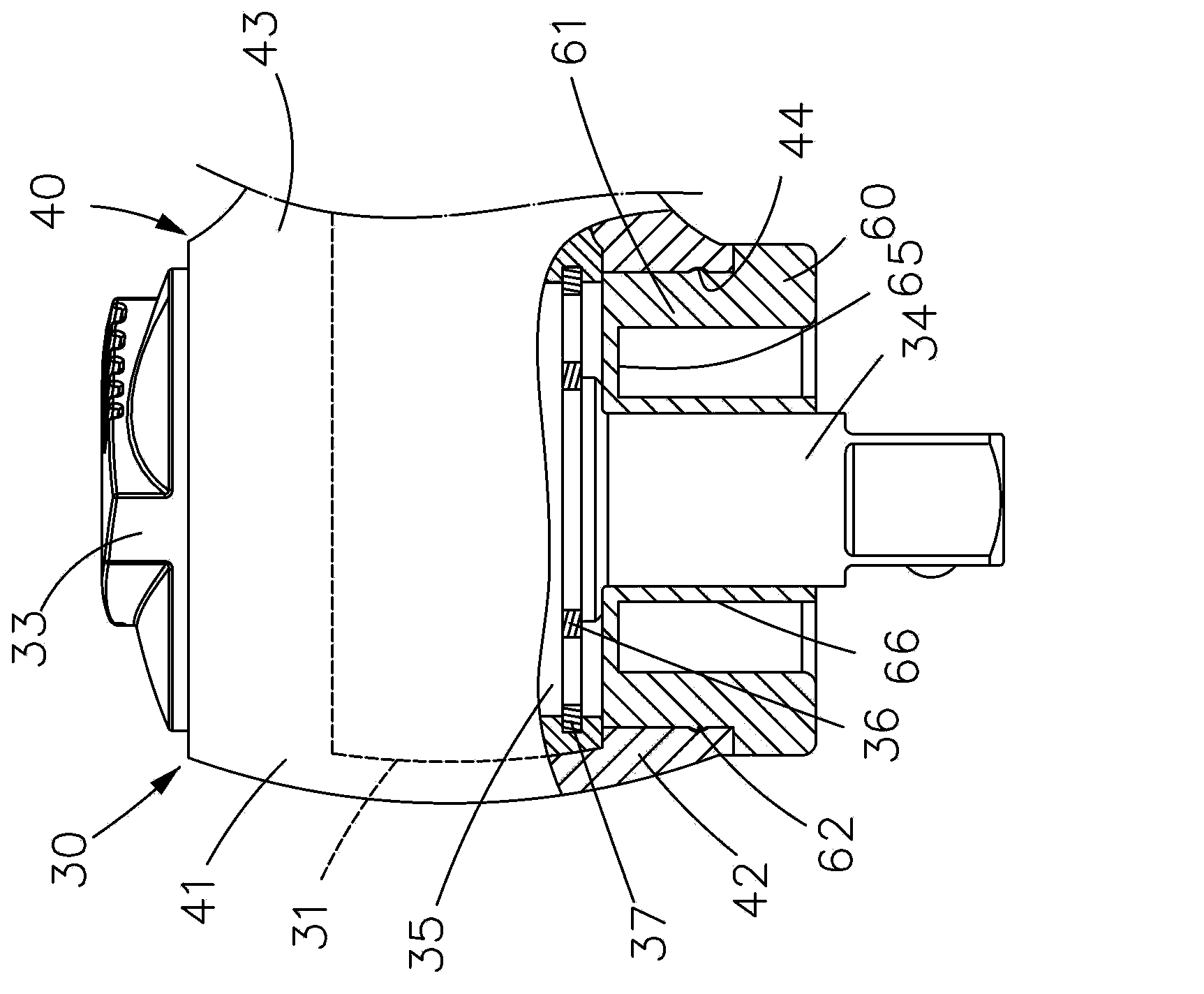

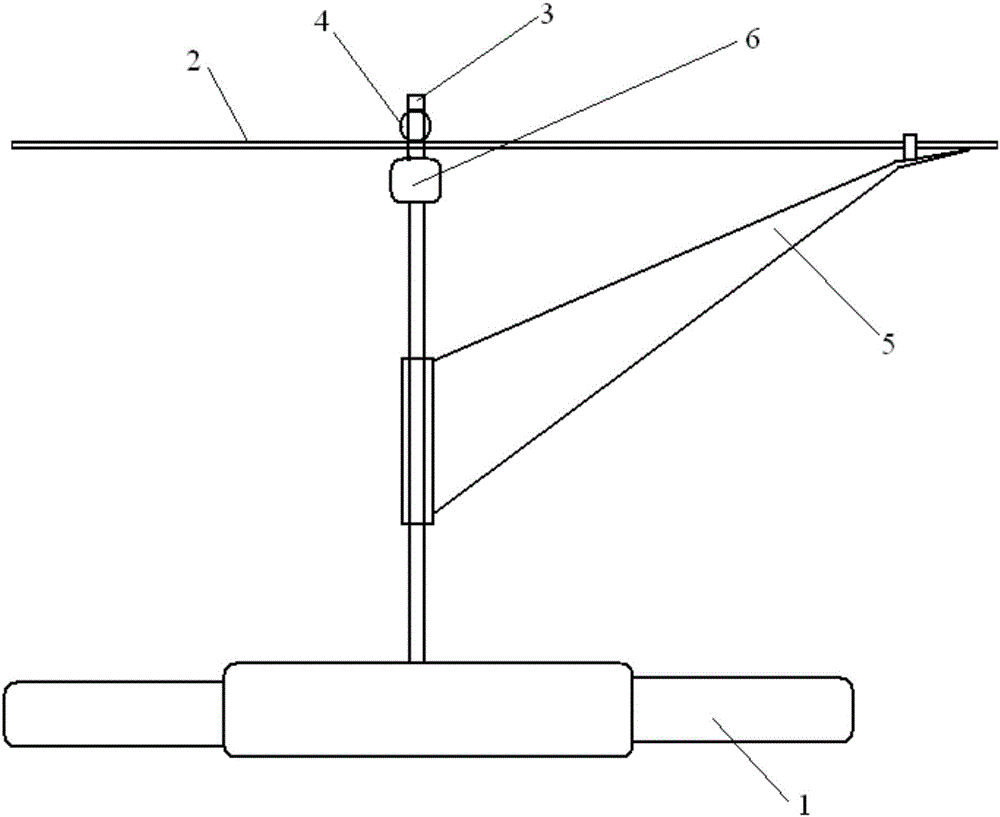

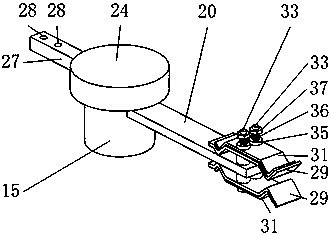

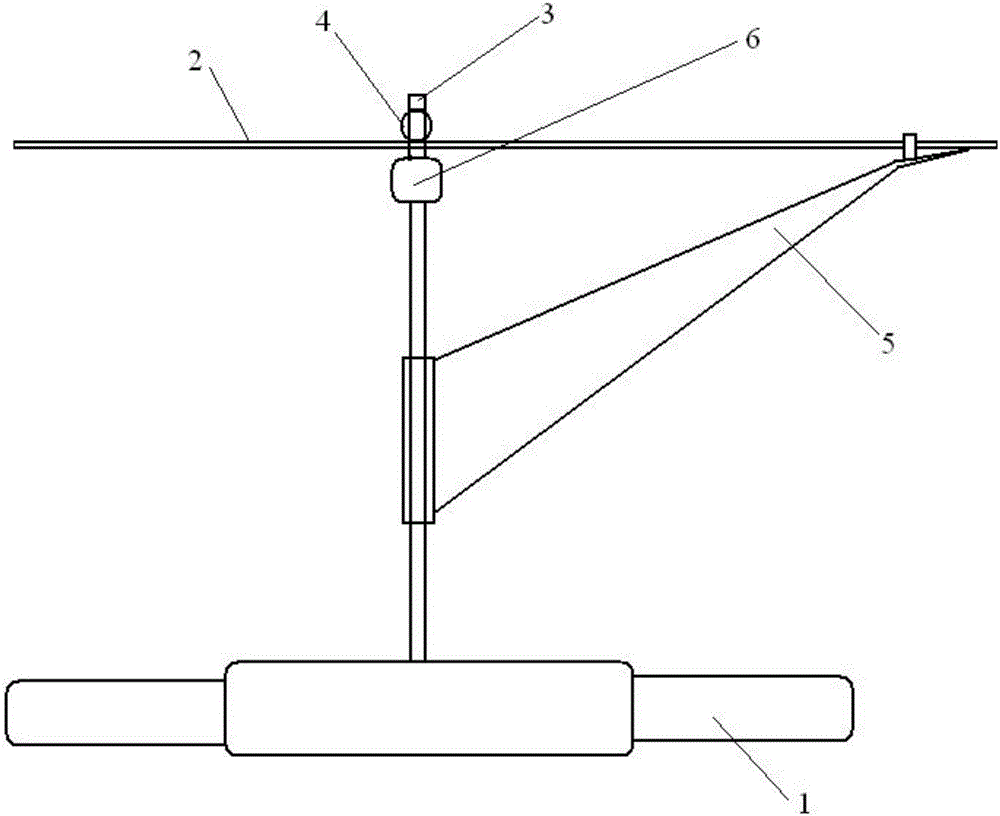

Running driving mechanism of power line inspection and maintenance unmanned aerial vehicle

InactiveCN106229887ASave electricitySmooth overhaulOverhead installationApparatus for overhead lines/cablesFrostRotary wing

The invention discloses a running driving mechanism of a power line inspection and maintenance unmanned aerial vehicle. A multi-rotor wing unmanned aerial vehicle (1) is adopted, a cable hook (3) is arranged on the multi-rotor wing unmanned aerial vehicle (1), and the multi-rotor wing unmanned aerial vehicle (1) is hung on a power line (2) by the cable hook (3) in a maintenance state of the power line (2) by the multi-rotor wing unmanned aerial vehicle (1). With the adoption of the abovementioned technical scheme, the running driving mechanism can stay on the power line for a long time, electric energy is saved, maintenance, fault removal and frost and freeze removal can be stably performed on the power line, and a potential risk of the power line is eliminated.

Owner:安徽翼讯飞行安全技术有限公司

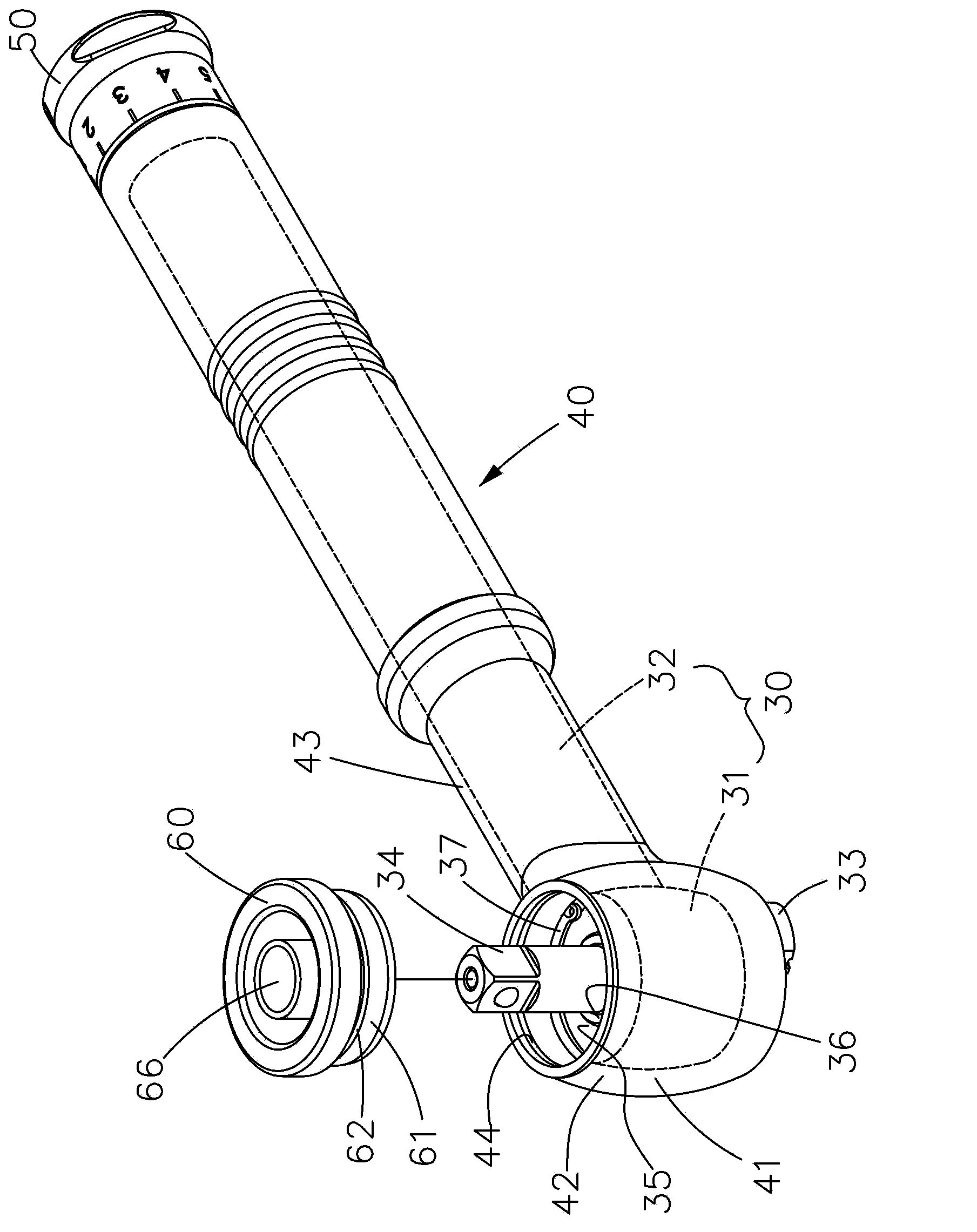

Tool and equipment for disassembling and assembling tuyere medium sleeve of iron-making blast furnace

ActiveCN113233384AEasy to pick and placeStable supportTuyeresLifting devicesMechanical engineeringMaterials science

The invention discloses a tool and equipment for disassembling and assembling a tuyere medium sleeve of an iron-making blast furnace. The tool comprises a driving device and a grabbing device connected with the driving device. Under the driving action of the driving device, the grabbing device is provided with a locking position opened to clamp the inner wall of the tuyere medium sleeve and an unlocking position contracted to release the tuyere medium sleeve. The end, away from the driving device, of the grabbing device is provided with a first stop piece capable of being clamped with a first opening edge of the tuyere medium sleeve, and the other end, close to the driving device, of the grabbing device is provided with a second stop piece capable of being clamped with a second opening edge of the tuyere medium sleeve. The grabbing device is further provided with a supporting piece, and the supporting piece can abut against the inner wall of the tuyere medium sleeve when the supporting piece is located at the locking position so that the tuyere medium sleeve can be prevented from shaking in the moving process. The clamping and fixing effect on the tuyere medium sleeve is better, so that the potential safety hazard that the tuyere medium sleeve falls off from the grabbing device is reduced.

Owner:济南华北升降平台制造有限公司

Novel wagon hook body conveyor

Owner:NINGXIA ZHONGYUAN TIANSHENG TECH

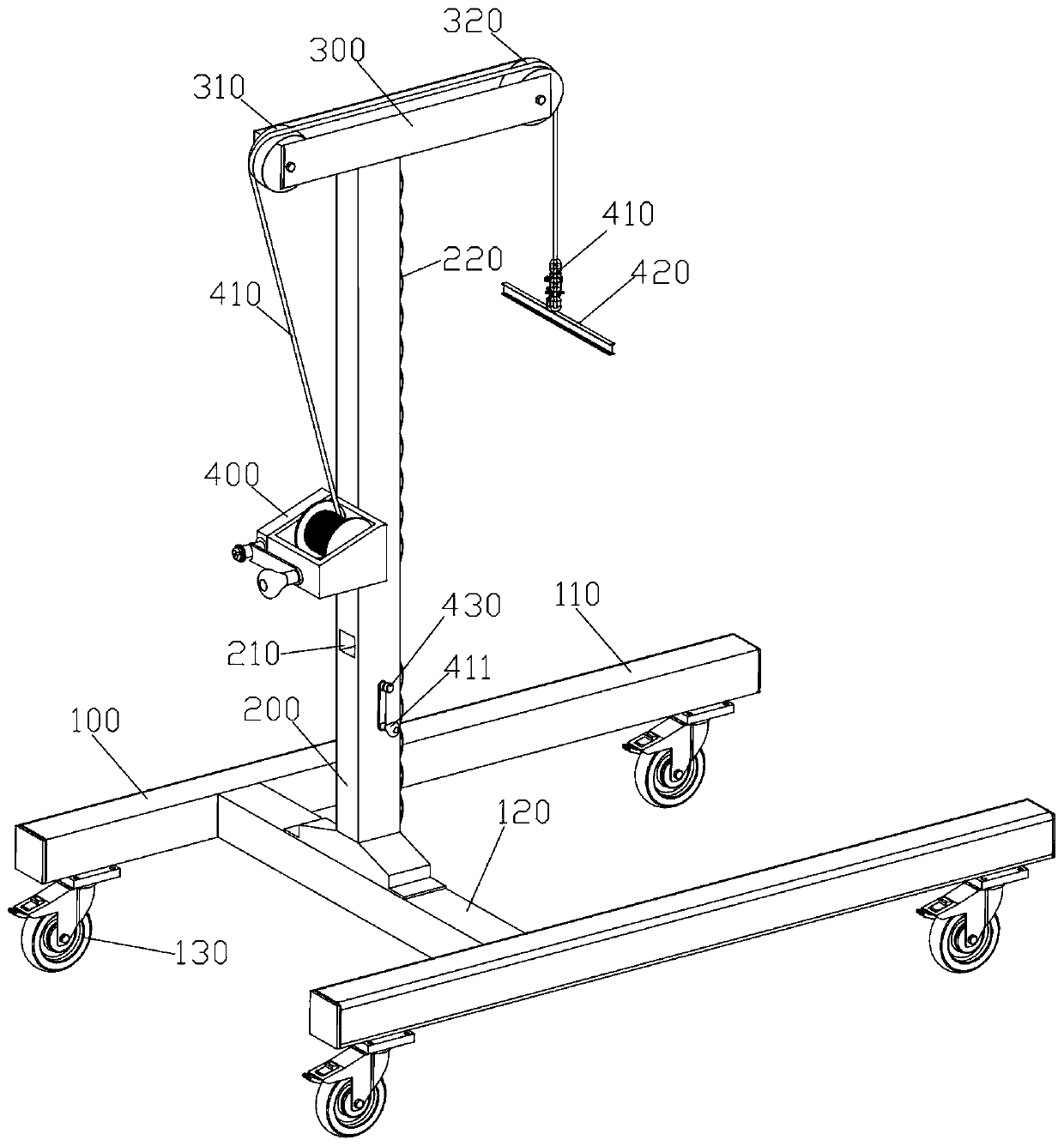

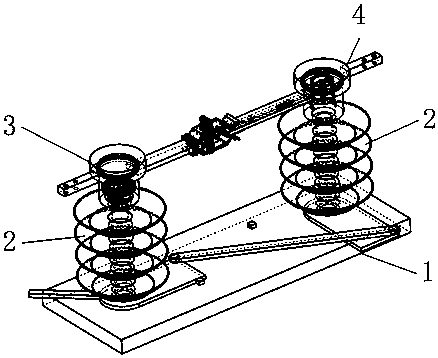

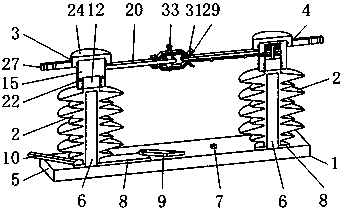

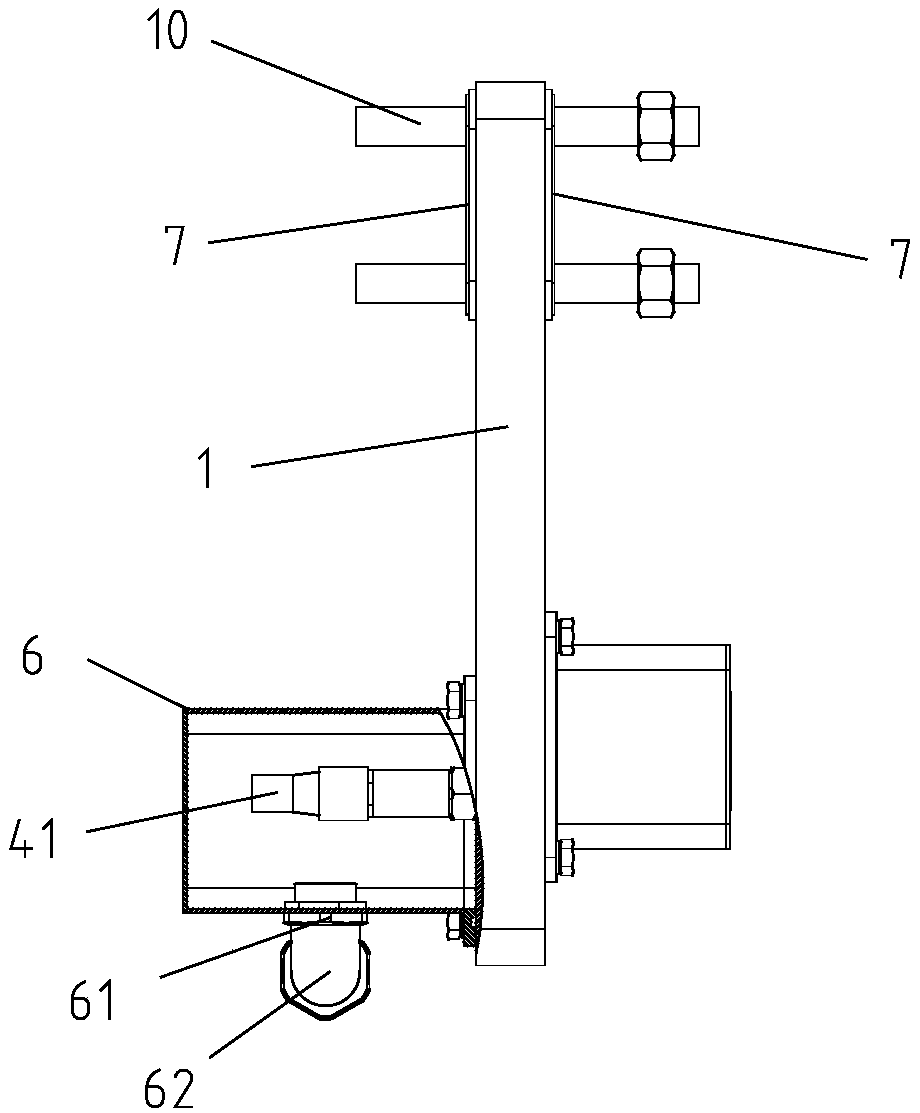

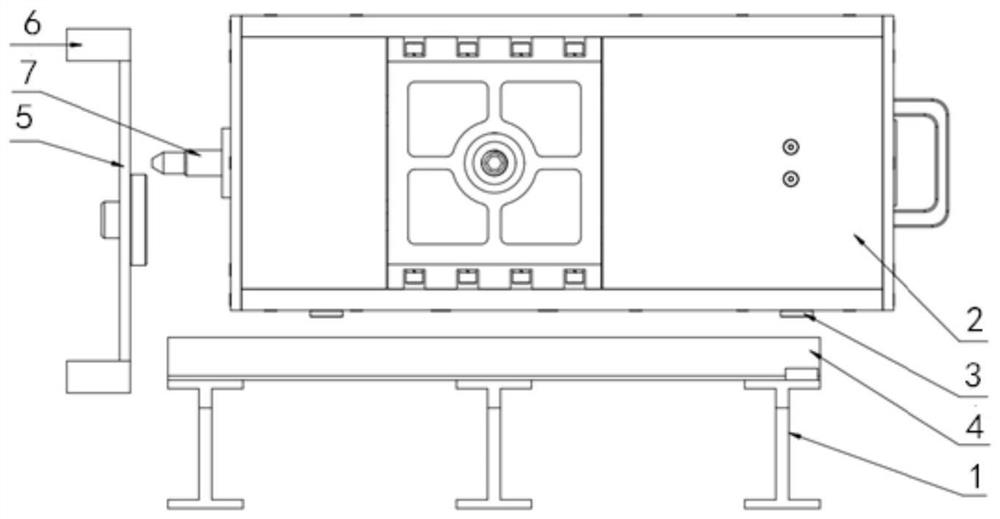

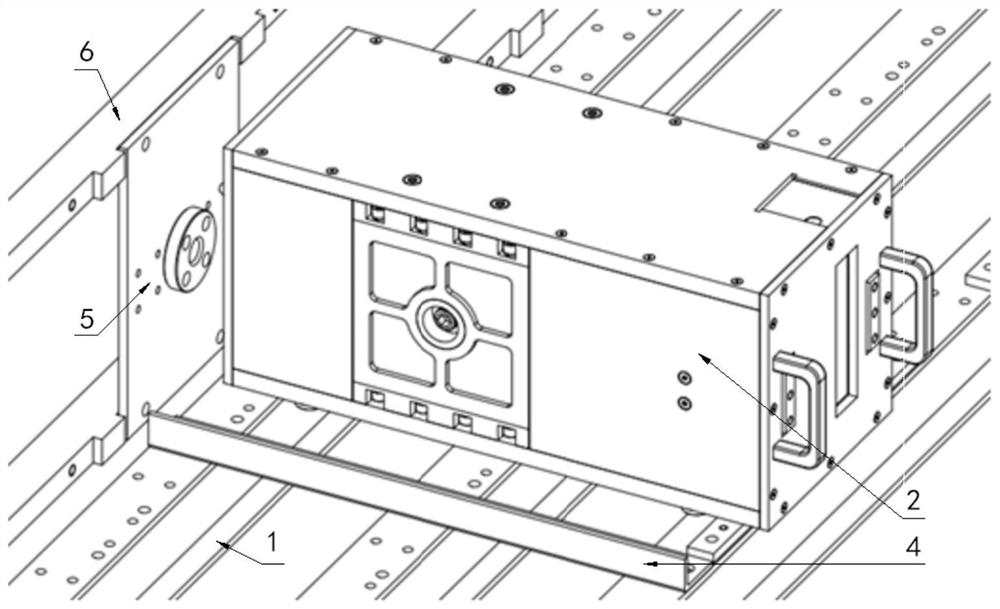

Marine frequency converter hoisting tool

ActiveCN109734008AEasy to operateImprove hoisting efficiencyPortable liftingFrequency changerBlock and tackle

The invention discloses a marine frequency converter hoisting tool. The marine frequency converter hoisting tool comprises main components including a base, a bearing support, a driving mechanism, movable wheels and the like. The movable wheels are arranged at the bottom of the base. The bearing support is longitudinally fixed to the base, and a pulley block is mounted at the top of the bearing support. The driving mechanism is mounted on the bearing support, and the leading-out end of the driving mechanism is connected with a frequency converter to be hoisted downwards through the pulley block. A through hole is formed in the bearing support in a penetrating manner, and the direction of the through hole is consistent with the line connecting direction of the pulley block. A cavity is formed in the bearing support at the bottom of the through hole, and a rotary disc mechanism is longitudinally mounted in the cavity. A limiting beam is movably and telescopically arranged in the throughhole, and the upper end of the rotary disc mechanism protrudes into the through hole and is in linkage with the limiting beam. The front end of the limiting beam abuts against the frequency converter.The marine frequency converter hoisting tool solves the technical problem a proper hoisting tool is in lack when a large frequency converter of an existing ship is repaired is solved.

Owner:POLAR RES INST OF CHINA

High-voltage disconnecting switch

PendingCN108962664AShorten maintenance timeAvoid dangerSwitches with movable electrical contactsHigh pressureSmall magnitude

The invention, which belongs to the field of disconnecting switches, in particular relates to a high-voltage disconnecting switch comprising a bearing base mechanism, an insulating porcelain column, acontact mechanism and a conductive plate mechanism and the like. The bearing base mechanism is mounted on a cable rod and is connected with a transmission mechanism arranged at the cable rod. When the high-voltage disconnecting switch needs to be disconnected for cable maintenance, severe corrosion may occur between the contact of the disconnecting switch and a second conductive plate and a sliding contact pad, so that disconnection of the high-voltage disconnecting switch becomes difficult. The maintenance worker applies forces to the transmission device arranged at the cable rod; the sliding contact pad slides to a small extent along a trapezoidal chute under the action of the transmission device arranged at the cable rod and thus the corrosion is broken; and thus the high-voltage disconnecting switch is disconnected easily, so that the cable maintenance is carried out smoothly. Therefore, the cable maintenance time is saved; and the danger caused by the failure of the disconnectingswitch is eliminated.

Owner:王雪梅

Drawout low-voltage power distribution cabinet

PendingCN108718051AEasy to install and maintainLarge operating spaceSwitchgear with withdrawable carriageSubstation/switching arrangement cooling/ventilationLow voltageCooling effect

The invention discloses a drawout low-voltage power distribution cabinet. The drawout low-voltage power distribution cabinet comprises a cabinet body, wherein a plurality of fixed plates are fixedly arranged in the cabinet body, an annular plate is arranged at an upper end of each fixed plate, a handle is fixedly connected to each annular plate, a plurality of installation plates are symmetricallyand fixedly connected to an inner side wall of each annular plate, an assembly hole is formed in each installation plate, the annular plate and the fixed plate are connected by a connection mechanism, insertion plates are fixedly connected to two ends of each sliding plate, slots are formed in inner side walls of two ends of each T-shaped sliding groove and are matched with the insertion plates,and a clamping mechanism is arranged in each slot. The drawout low-voltage power distribution cabinet is convenient to install and maintain and simple to operate, and the working efficiency of a worker is effectively improved; and by expanding a cooling space in the cabinet body and fully utilizing external natural airflow, the cooling effect is improved.

Owner:SHANGHAI PEOPLE ELECTRICAL APPLIANCE GROUP

Ice scraping structure of special unmanned aerial vehicle for patrolling and overhauling power line

InactiveCN106347647ASmooth overhaulEliminate hidden dangersAircraft componentsOverhead installationUncrewed vehicleEngineering

The invention discloses a special unmanned aerial vehicle for patrolling and overhauling a power line. A cable pothook (3) is arranged on a multi-rotor unmanned aerial vehicle (1); when the multi-rotor unmanned aerial vehicle (1) overhauls the power line (2), the multi-rotor unmanned aerial vehicle (1) is suspended on the power line (2) through the cable pothook (3); a frozen shovel (5) is arranged on the cable pothook (3); the position of the frozen shovel (5) is arranged outside the range of a horizontal projection of the multi-rotor unmanned aerial vehicle (1); a heating device of the frozen shovel (5) is arranged on the multi-rotor unmanned aerial vehicle (1). By adopting the technical scheme, the ice scraping structure can stay on the power line for a long time, the electric energy is saved, and the ice scraping structure can stably stay on the power line so as to be used for overhauling, troubleshooting, defrosting, defreezing, and eliminating hidden dangers of the power line.

Owner:安徽翼讯飞行安全技术有限公司

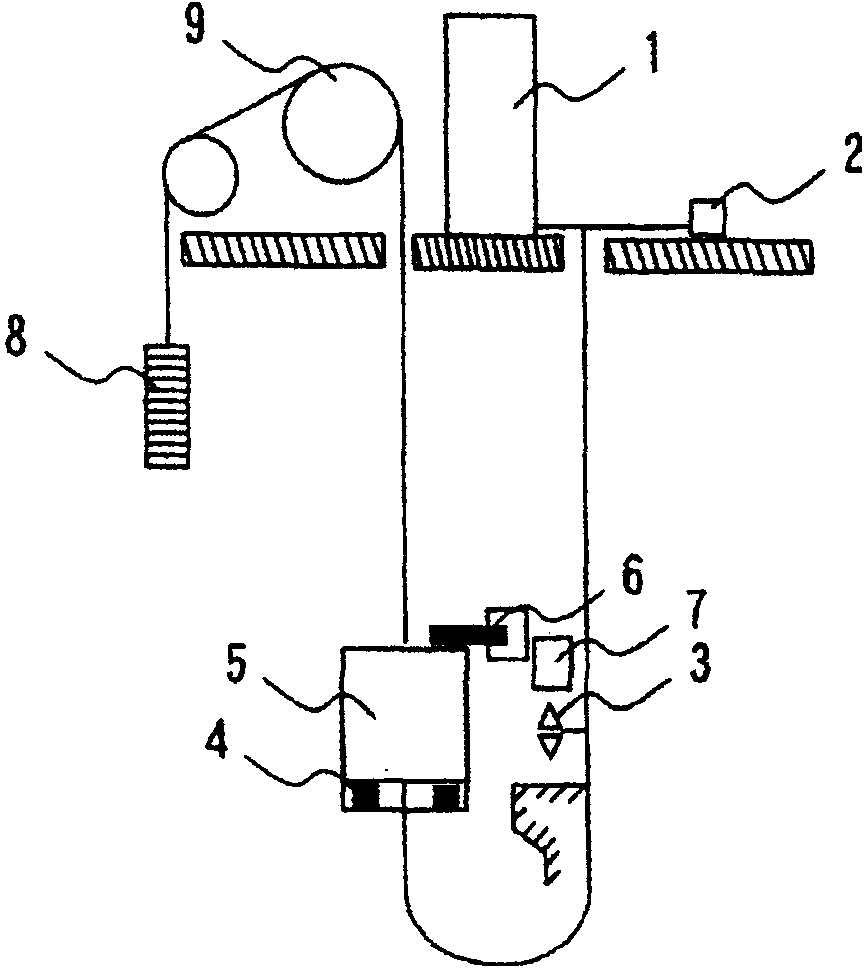

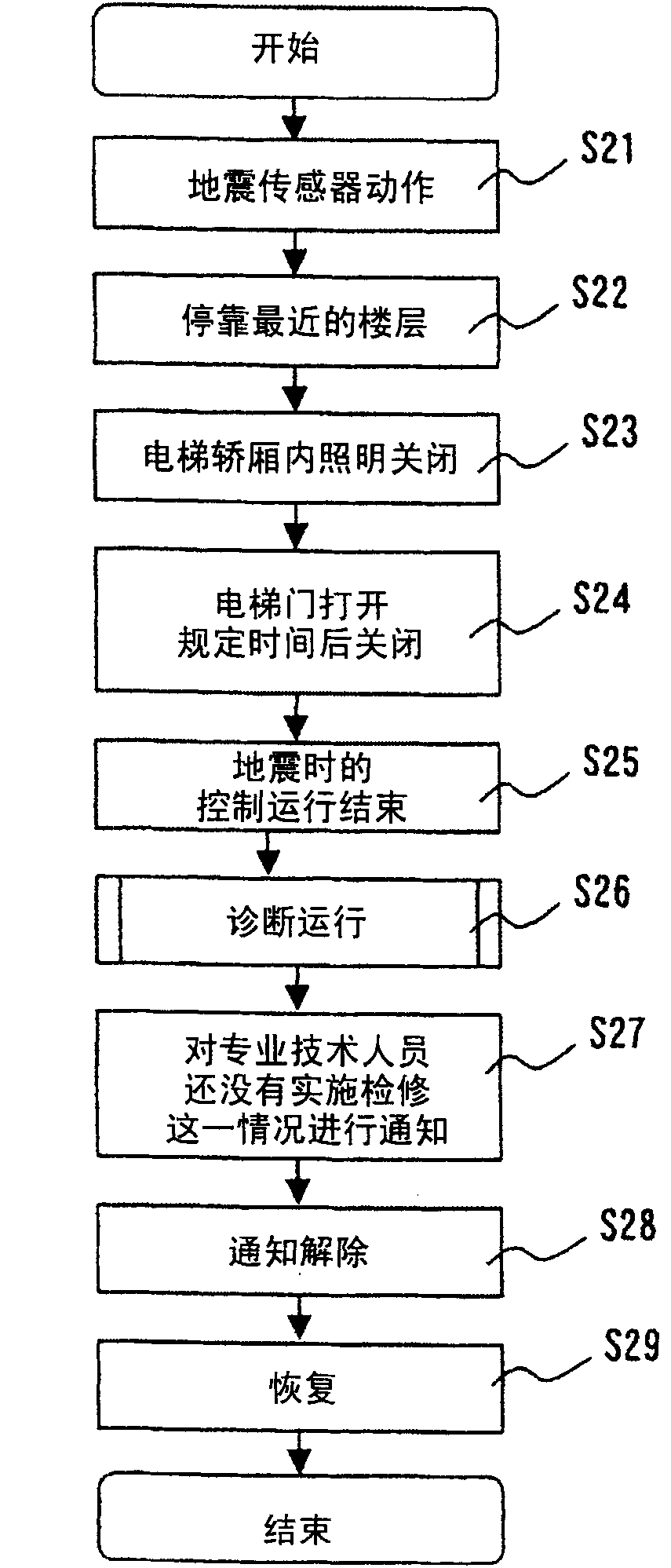

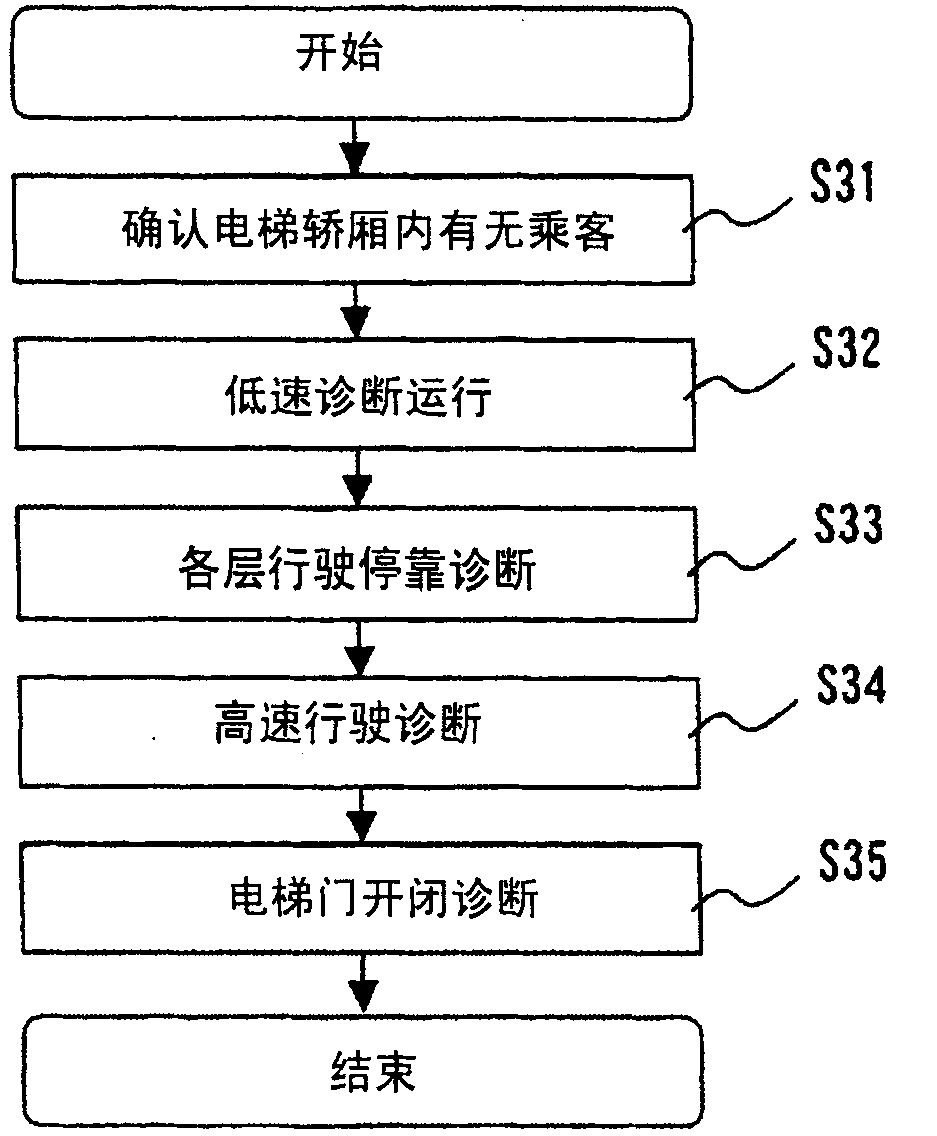

Elevator control device

ActiveCN101016132BThe overhaul was carried out smoothlySmooth overhaulElevatorsControl engineeringElevator control

The invention provides a control device for an elevator informing an expert of the elevator and a user of the elevator after completion of automatic recovering work when diagnosis operation is automatically performed not depending on inspection by the expert of the elevator and it is recovered from operation-halt. The control device for the elevator according to the present invention is provided with a means for making the elevator to operation-halt when a magnitude of shaking of a predetermined value or more is sensed; and a means for automatically performing diagnosis operation when it becomes operation-halt and recovering it from operation-halt. Further, the device is provided with a means for informing existence of execution of inspection by the expert after the diagnosis operation.

Owner:HITACHI LTD +2

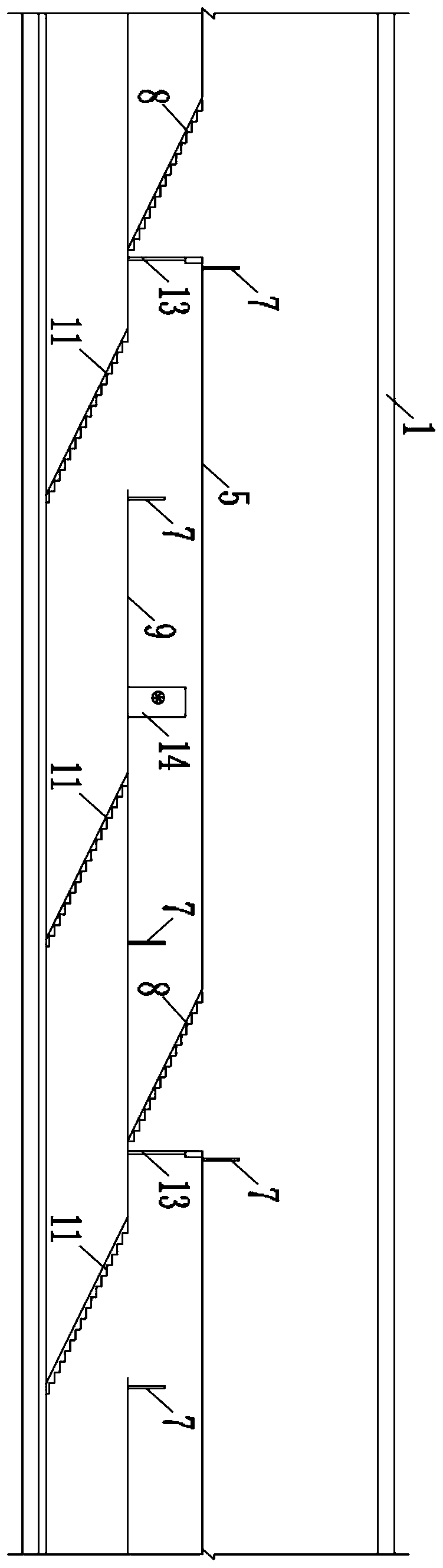

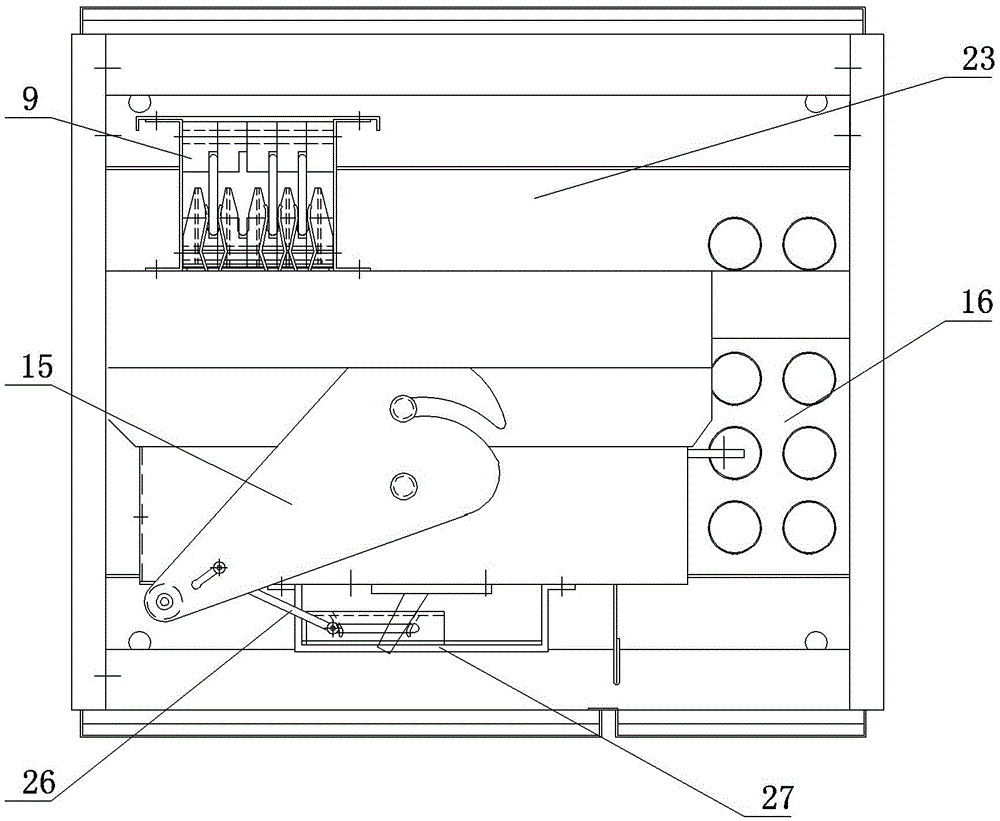

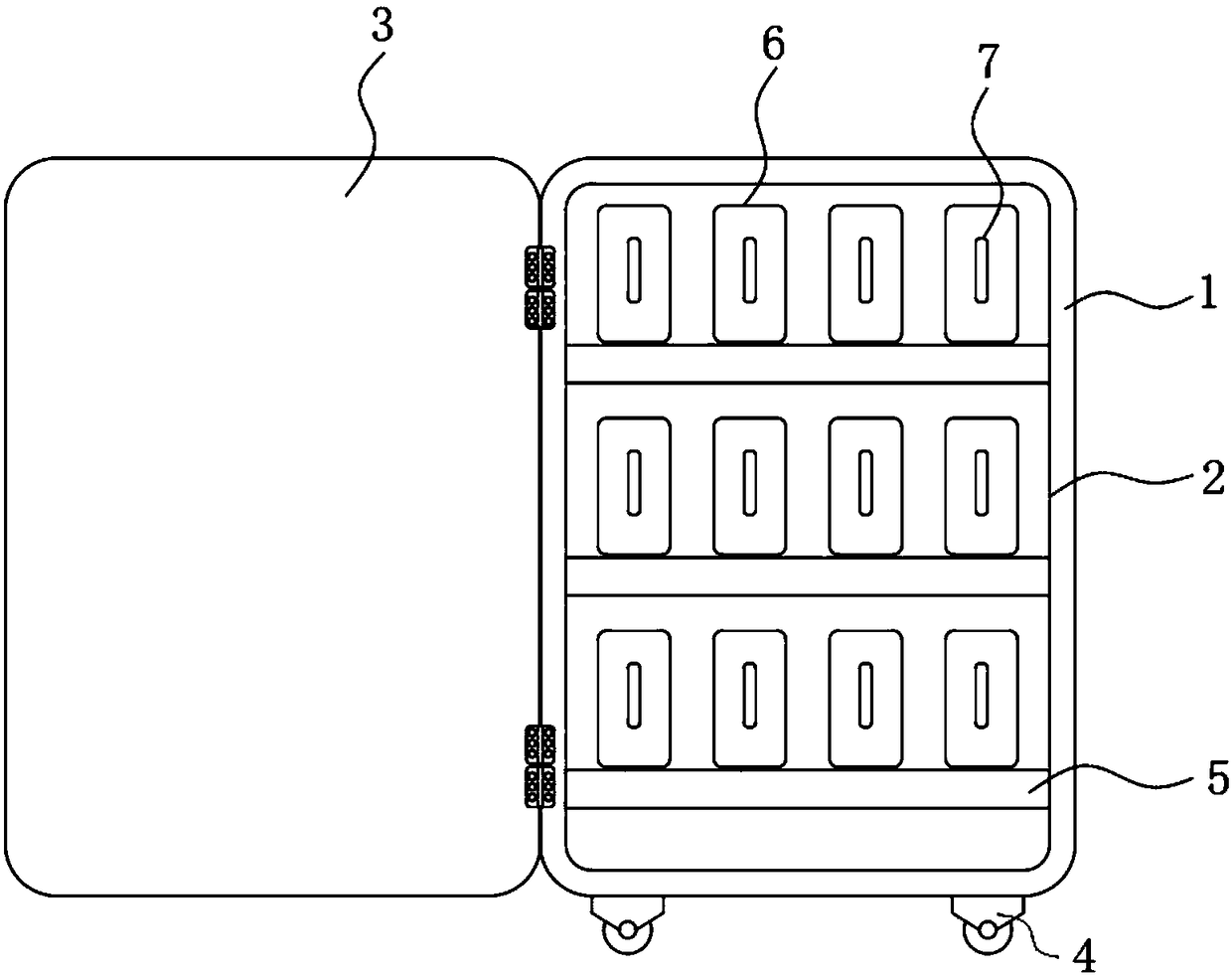

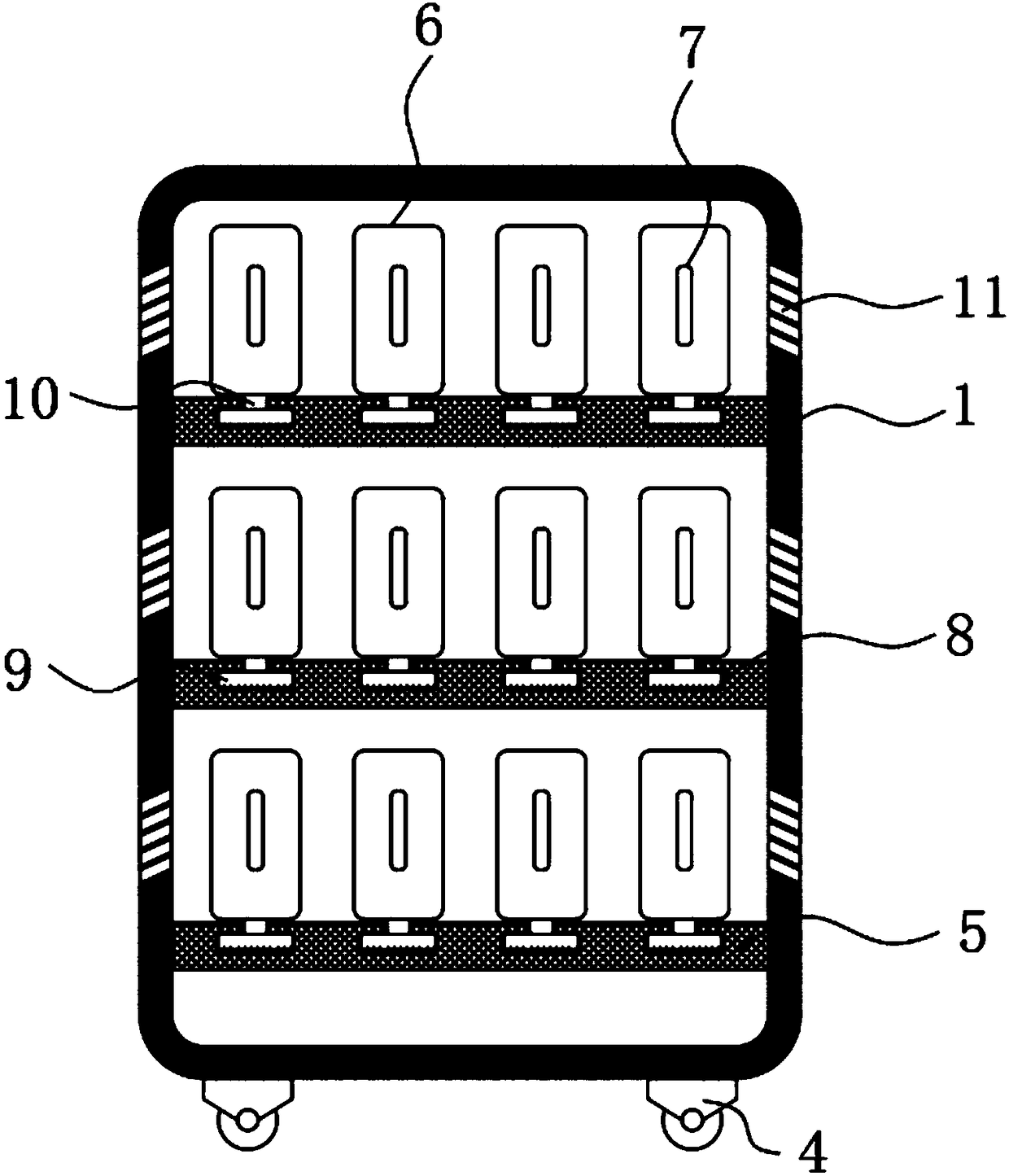

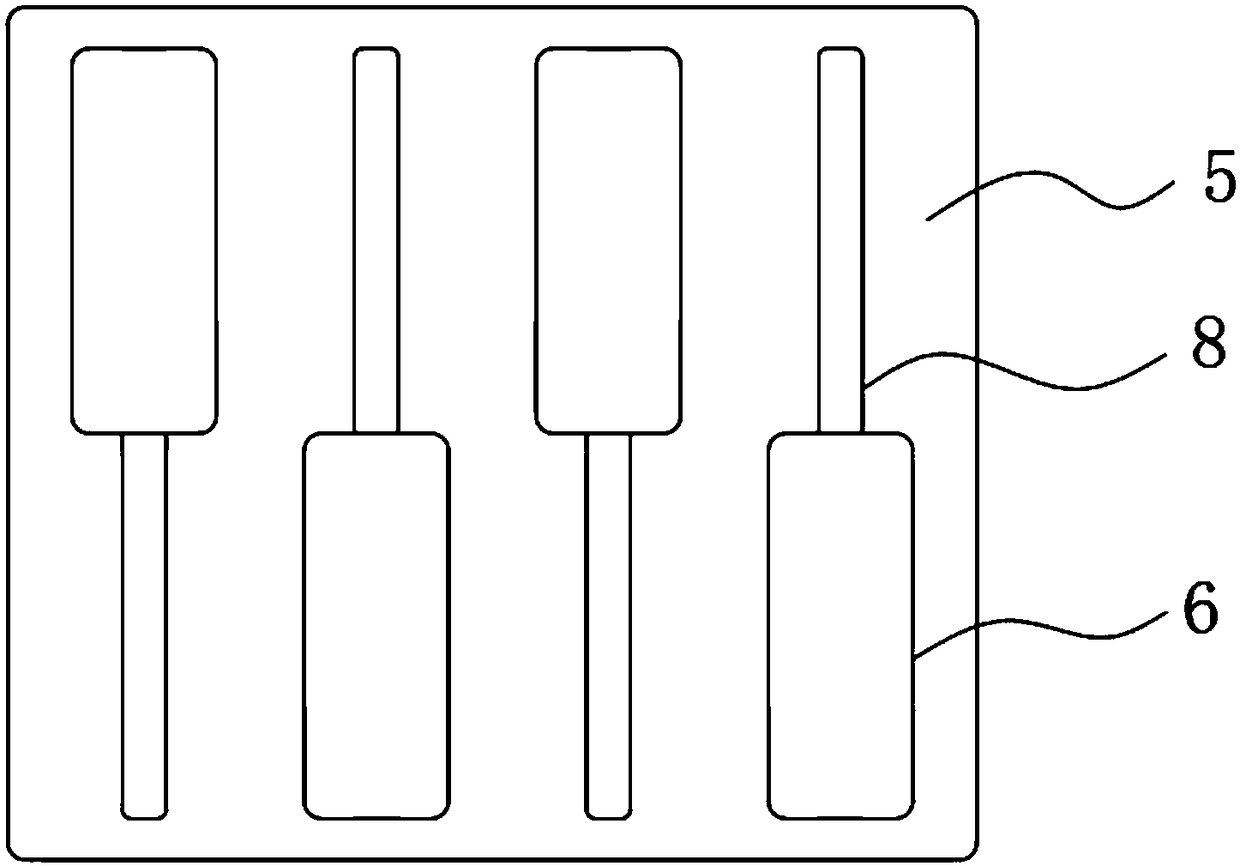

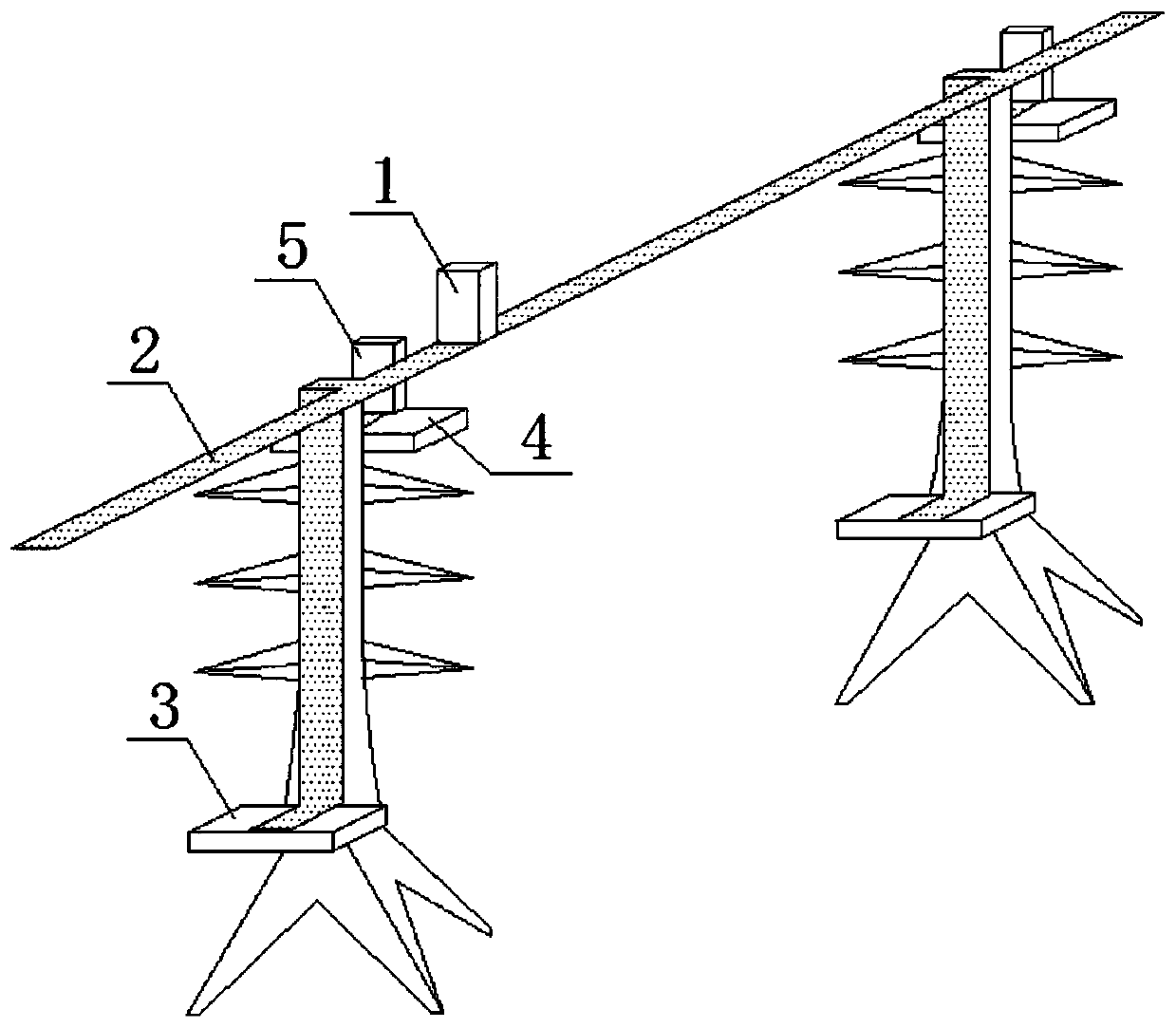

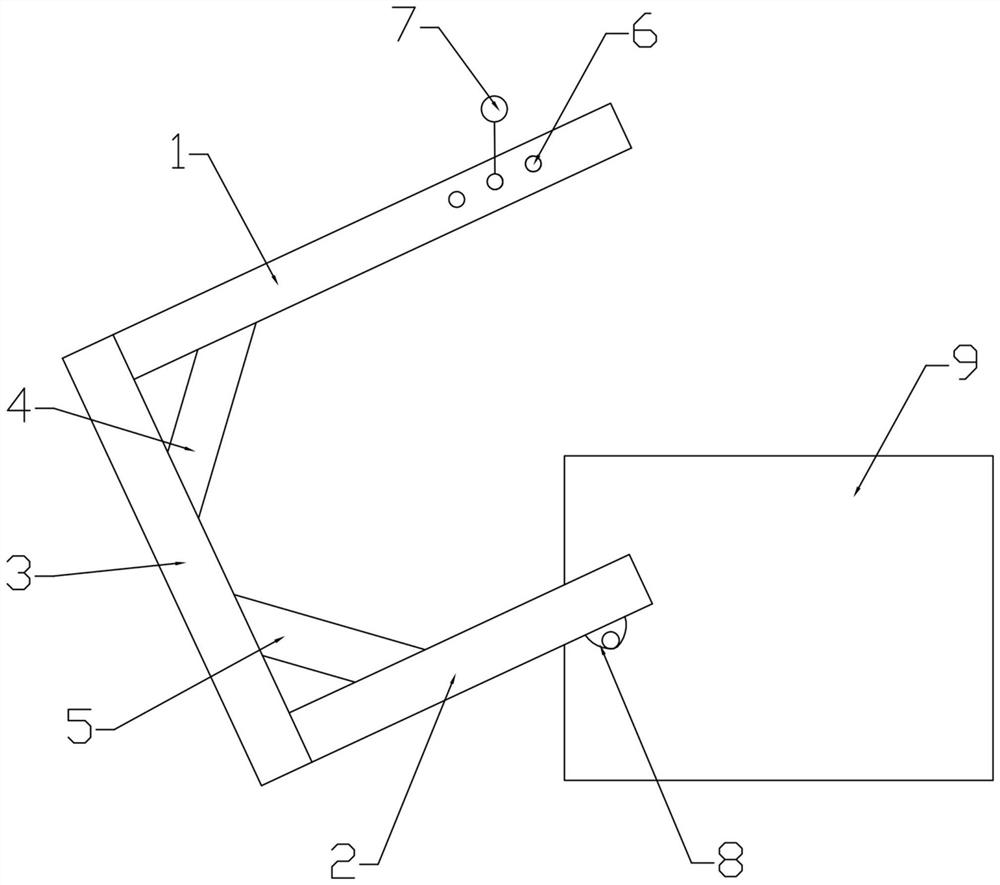

Equipment cabinet assembly suitable for all-terrain maintenance for shared towers

ActiveCN108649484BAffect power supply reliabilityAffect reliabilityApparatus for overhead lines/cablesSteep slopeTower

The invention provides an equipment box cabinet component suitable for all-terrain overhaul for shared towers. The equipment box cabinet component comprises an equipment box cabinet, rails, an overhaul platform, a running platform and a line wall; the rails are connected between the tops of two adjacent towers, between the top of the tower and the running platform and between the top of the towerand the overhaul platform; the equipment box cabinet are arranged on the rails and can horizontally move among the towers along the rails or vertically move along the towers; the line wall is arrangedon the running platform, the line wall is inserted into the equipment box cabinet; and when the tower equipment is overhauled, the tower equipment can be repaired without applying for line power failure or climbing, thereby avoiding the impact of the overhaul process on the reliability of the power line and power loss, and the equipment box cabinet component is suitable for performing smooth overhaul on the equipment built on towers in dangerous areas such as steep slopes.

Owner:YUNNAN POWER GRID CO LTD ELECTRIC POWER RES INST

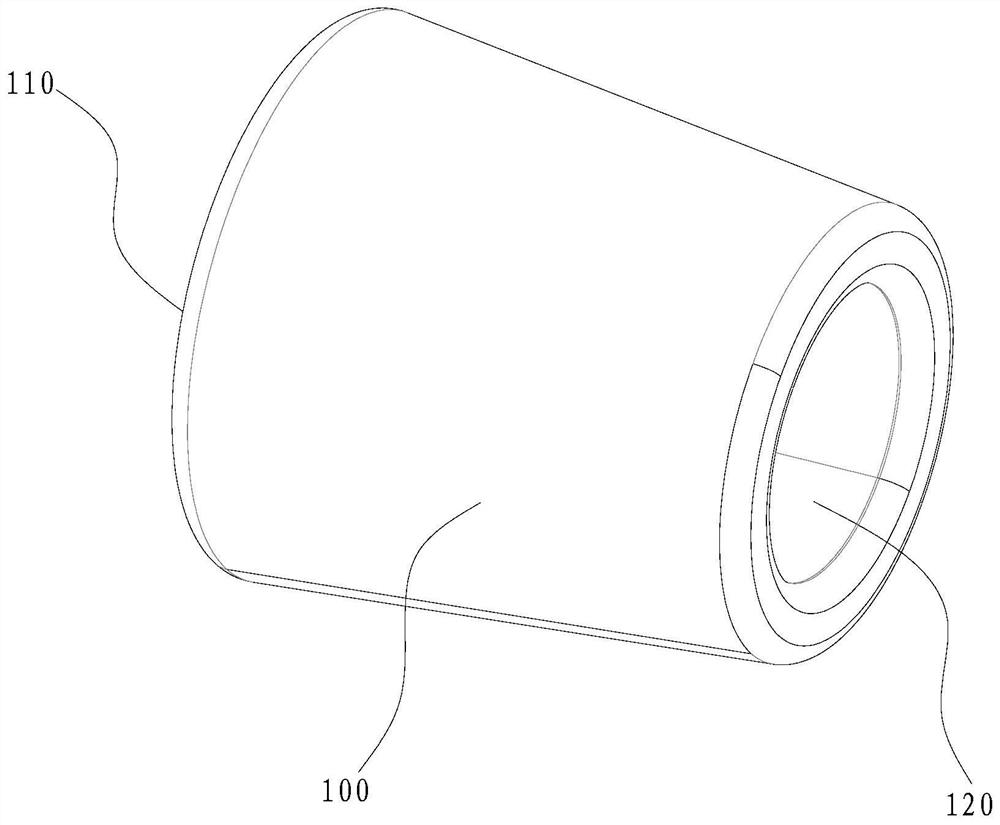

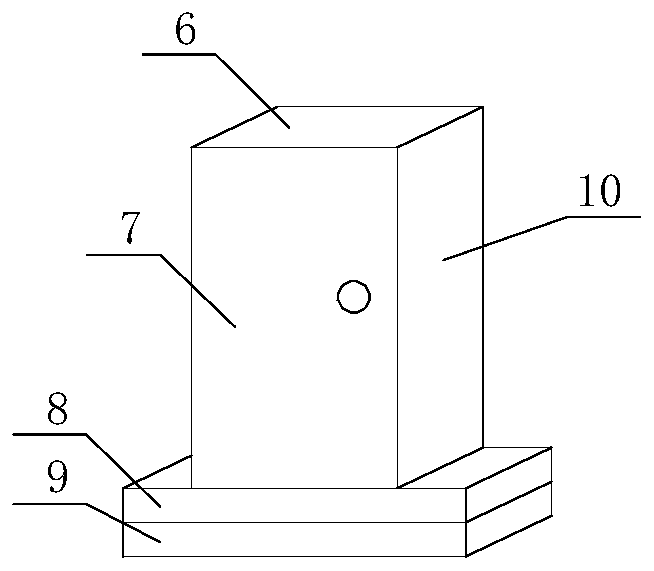

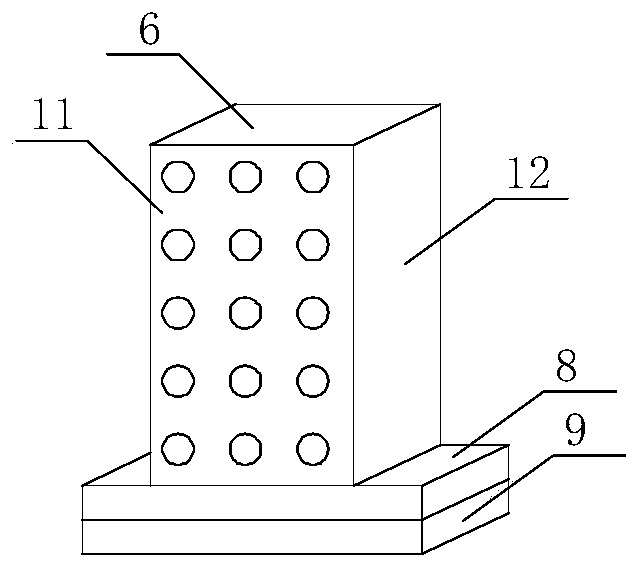

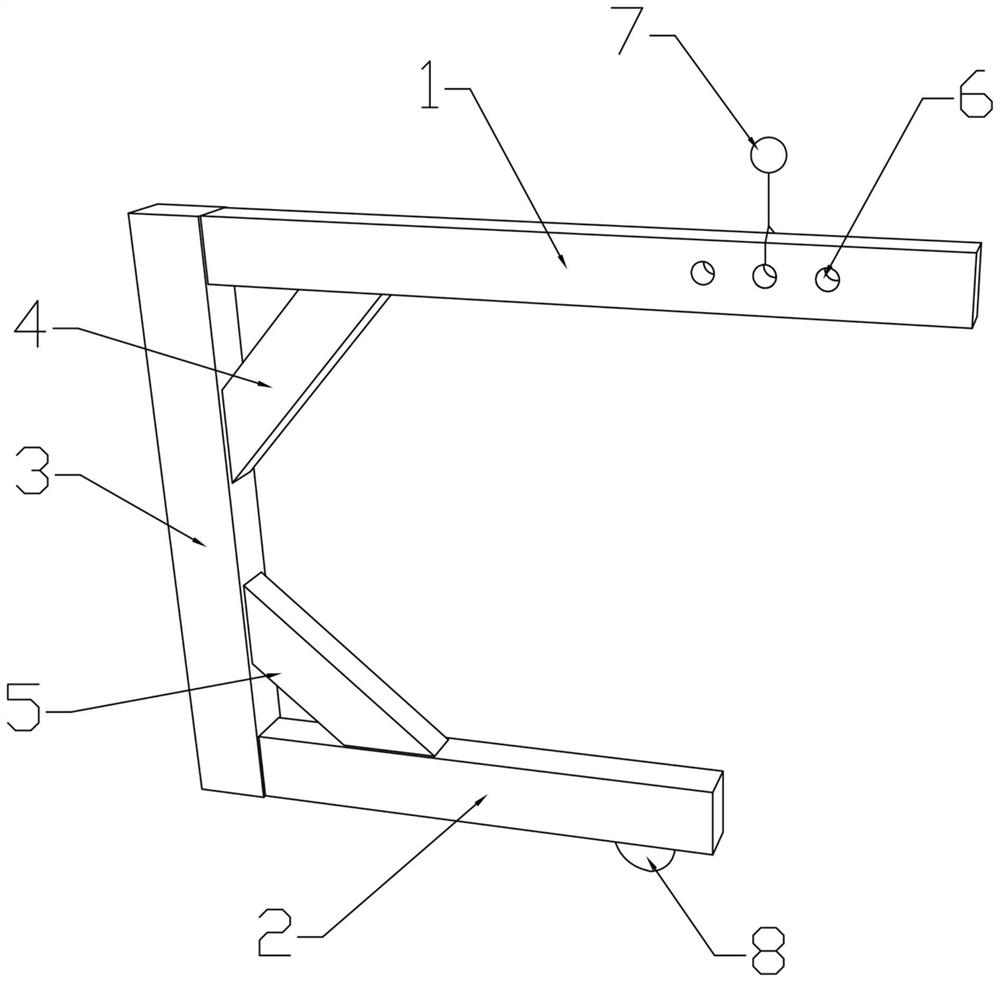

Special hoisting tool for overhauling

PendingCN113071977AStable hoistingHoisting smoothlyLoad-engaging elementsControl engineeringElectric machinery

The invention discloses a special hoisting tool for overhauling. The hoisting tool comprises a hoisting arm and a suspension arm, the hoisting arm and the suspension arm are arranged in parallel, a connecting arm is fixedly arranged between the hoisting arm and the suspension arm and is perpendicular to the hoisting arm and the suspension arm, a lifting diagonal draw bar is fixedly arranged between the lifting arm and the connecting arm, a suspension diagonal draw bar is fixedly arranged between the suspension arm and the connecting arm, a plurality of hoisting holes are formed in the end part, far away from the connecting arm, of the hoisting arm, hoisting rings are connected to the hoisting holes, and a suspension ring is connected and fixed to the bottom surface of the end part, away from the connecting arm, of the suspension arm. Compared with the prior art, the hoisting tool has the advantages of being simple in structure, convenient to use, capable of facilitating space shielding operation, time-saving and labor-saving; electric machinery can be stably hoisted, a hoisting point capable of adjusting the gravity center is designed at the upper part, the arm of force is adjusted, so that the purpose of smooth overhauling is achieved, the manual hoisting time is saved, and the working efficiency is greatly improved; and the practicability and the market popularization value are very high.

Owner:华能新华发电有限责任公司

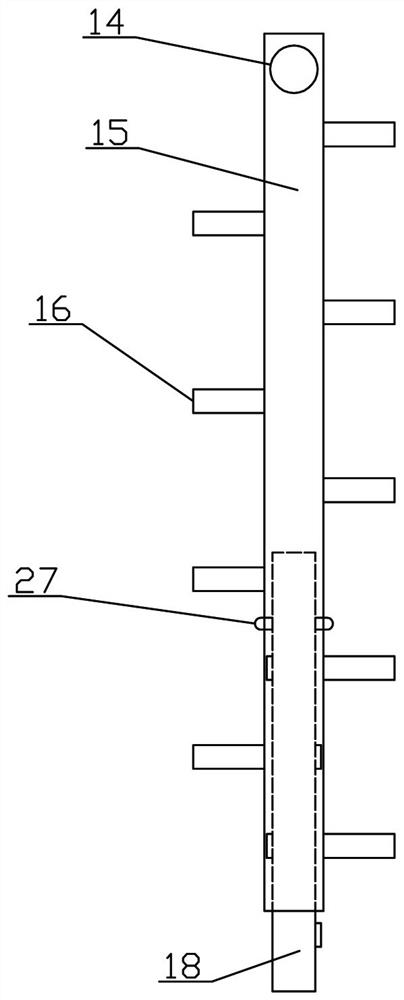

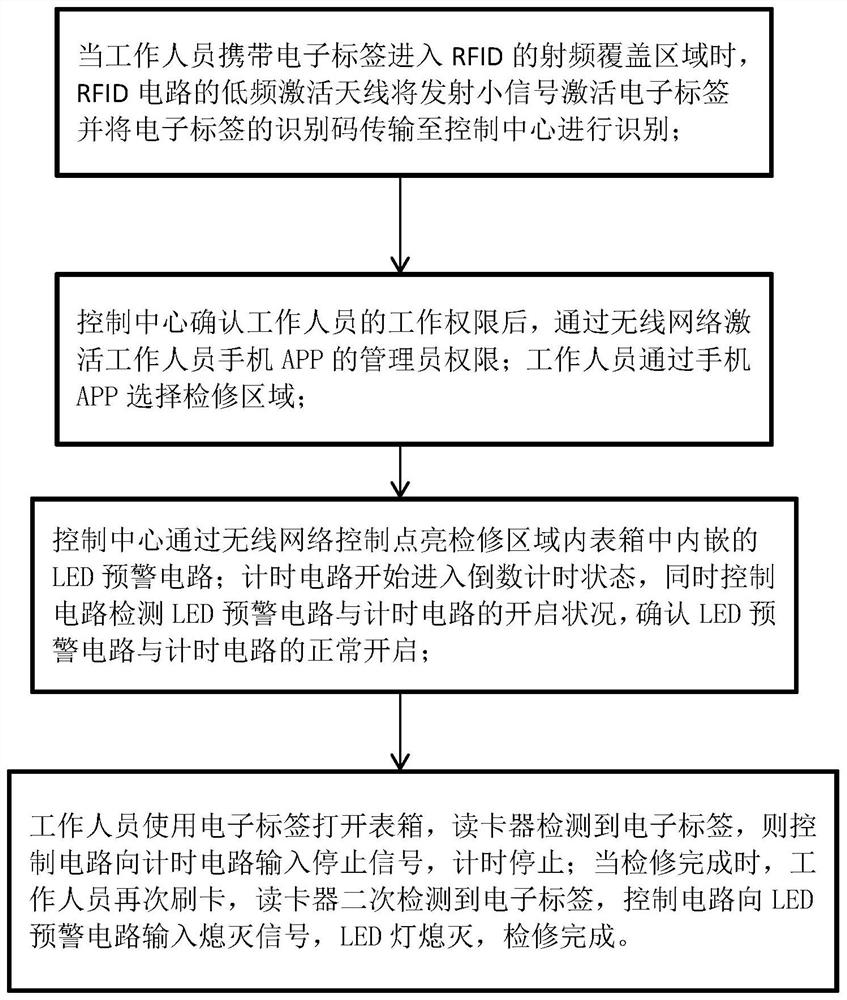

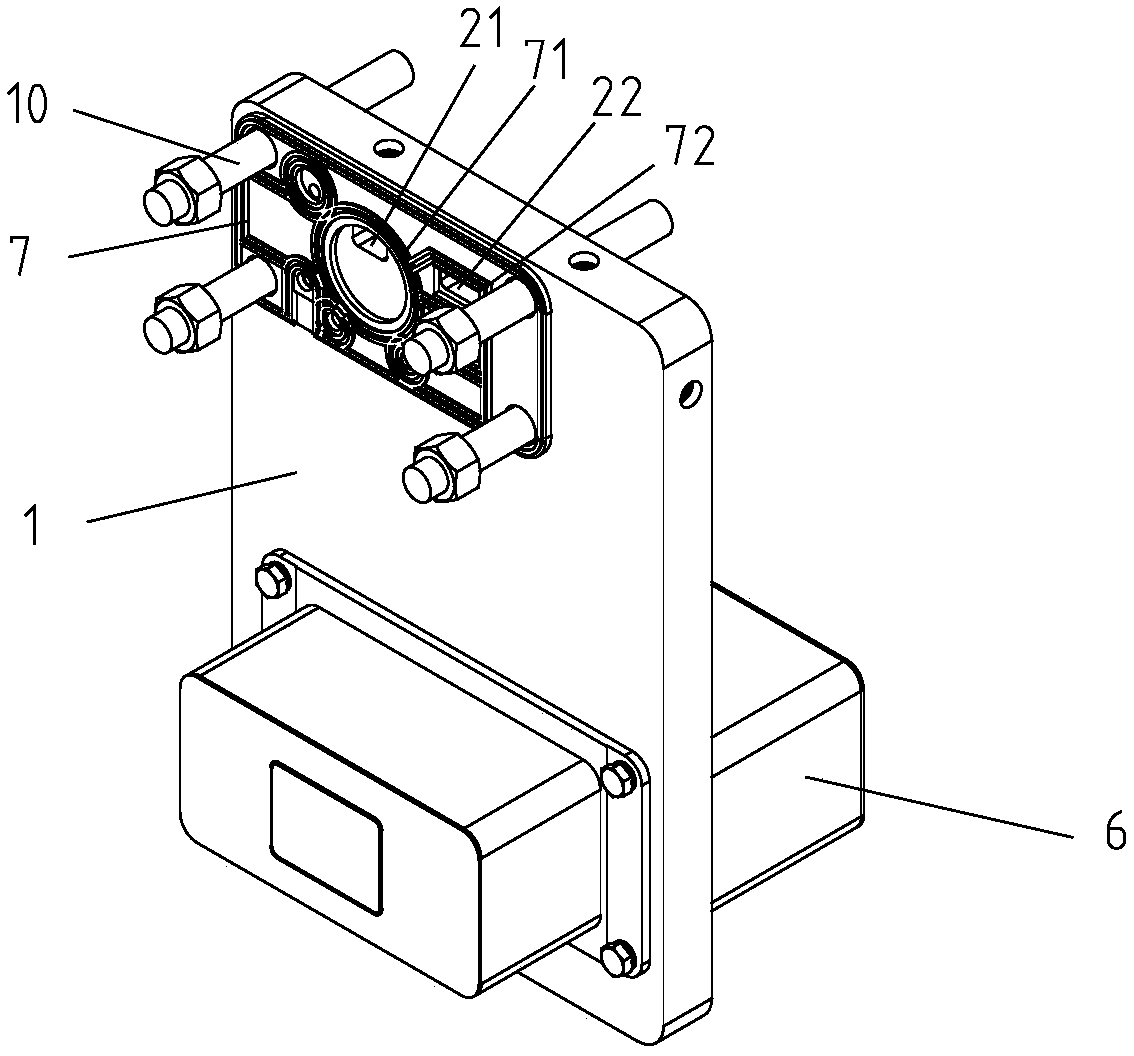

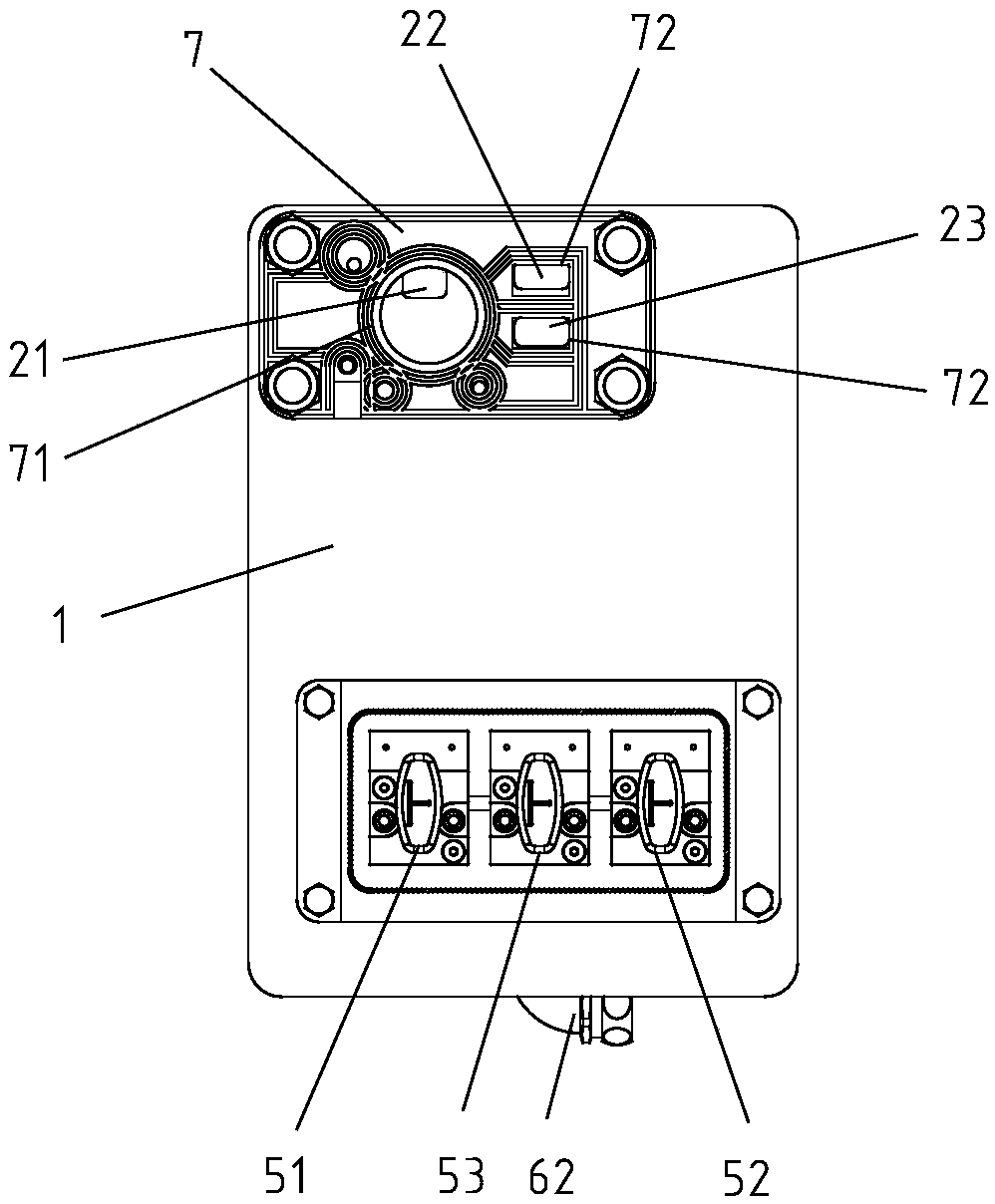

Rod frame type meter box based on RFID and maintenance method thereof

PendingCN114545044ASmooth overhaulPrevent missing detection and missed detectionTime integral measurementInformation technology support systemWireless transmissionControl circuit

The invention discloses an RFID-based rod frame type meter box and a maintenance method thereof. The RFID-based rod frame type meter box comprises an RFID circuit, a wireless transmission circuit, a Bluetooth circuit, a timing circuit, a control circuit, an LED early warning circuit and an alarm circuit which are installed on the inner side of the meter box. An electronic tag is activated through a low-frequency activation antenna in an RFID circuit, countdown of all meter boxes in a maintenance area is activated through a control center, and a worker is reminded to maintain the meter boxes in time through buzzer alarm and background alarm after countdown; and meanwhile, the Bluetooth module is used for replacing the control center to complete the work of reminding missing detection when the meter box cannot receive an activation signal of the control center, so that missing detection and missing detection are doubly guaranteed.

Owner:HUZHOU ELECTRIC POWER SUPPLY CO OF STATE GRID ZHEJIANG ELECTRIC POWER CO LTD +1

104 distribution valve air pressure monitoring module

The invention discloses an air pressure monitoring module for a 104 distribution valve. The module comprises an air path plate installed between a main valve part and a middle body of the 104 distribution valve. A first main air hole, a second main air hole and a third main air hole formed in the main valve part are communicated with a first auxiliary air hole, a second auxiliary air hole and a third auxiliary air hole of the middle body through a first connecting hole, a second connecting hole and a third connecting hole formed in the air path plate respectively. A first detection channel communicated with the first connecting hole, a second detection channel communicated with the second connecting hole and a third detection channel communicated with the third connecting hole are arranged in the air path plate. The air pressure monitoring module for the 104 distribution valve is simple and compact in structure and can be additionally installed between the main valve part and the middle body of the 104 distribution valve directly to lead out an air path connecting a train pipe, a braking cylinder and an auxiliary air cylinder of a railway vehicle for air pressure detection; an original braking pipeline of the railway vehicle does not need to be refitted, so that the workload is small; the module can be additionally installed on the existing railway vehicle directly, so that compatibility is high; the number of connecting portions is small, so that sealing is convenient, and the hidden danger of leakage is small.

Owner:CRRC QINGDAO SIFANG ROLLING STOCK RES INST

Rack roller overhauling fixture for rough mill

ActiveCN102581544BAvoid collisionAvoid interferenceMetal working apparatusUltimate tensile strengthMechanical engineering

Owner:CHONGQING IRON & STEEL CO LTD

A gas steamer

The invention relates to a gas rice steaming oven. The defect that a heater of an existing rice steaming oven is inconvenient to overhaul is overcome. According to the gas rice steaming oven, an installation frame is arranged at the lower end of an oven body, a first heat insulation plate is arranged on the installation frame, a heater and an ignition device are fixed to the installation frame, a controller and a handle are fixed to the first heat insulation plate, the oven body is provided with a sliding rail, a sliding groove matched with the sliding rail is formed in the installation frame, the installation frame can be conveniently drawn out of the oven body when the heater is overhauled, and the heater is quite convenient to overhaul; the oven body is further provided with a supporting plate, the supporting plate is provided with a gas inlet hole and plays a role in supporting the installation frame after the installation frame is inserted into the oven body, the installation frame is firmly fixed, and the stability of the rice steaming oven is improved.

Owner:JIAXING ZHISHENG KITCHENWARE MFG CO LTD

A classroom lighting intelligent control lighting system

ActiveCN111148328BSolve problems that are not conducive to quick maintenanceQuick repairElectrical apparatusEnergy saving control techniquesEngineeringLighting system

The invention discloses a classroom lighting intelligent control lighting system, which comprises an intelligent system control box body, an inspection port is opened on the top of the intelligent system control box body, and a sealed door is movably installed inside the inspection port, and the inspection port A circular placement groove is provided on the front side of the inner wall, an extruding device is fixedly installed inside the circular placement groove, and a circular groove is provided on the front side of the airtight door. In this invention, by setting the intelligent system control box body, inspection port, sealed door, circular placement groove, extrusion device, extrusion spring, moving block, connecting block, push-pull handle, pushing block, circular groove, fixing mechanism, The combination of pneumatic cylinder, piston, extrusion rod, circular stopper, fixed rod, limit groove, limit block, strip groove, hinged seat and lifting groove solves the troublesome process of existing maintenance, which is not conducive to For the problem of quick maintenance, the classroom lighting intelligently controls the lighting system, which has the advantage of quick maintenance.

Owner:刘阔森

Sliding type direct-current energy dissipation device unit fixing device and using method

PendingCN113258455AQuick changeStable replacementSubstation/switching arrangement detailsElectric power transfer ac networkEngineeringControl theory

Owner:BEIJING POWER EQUIP GRP

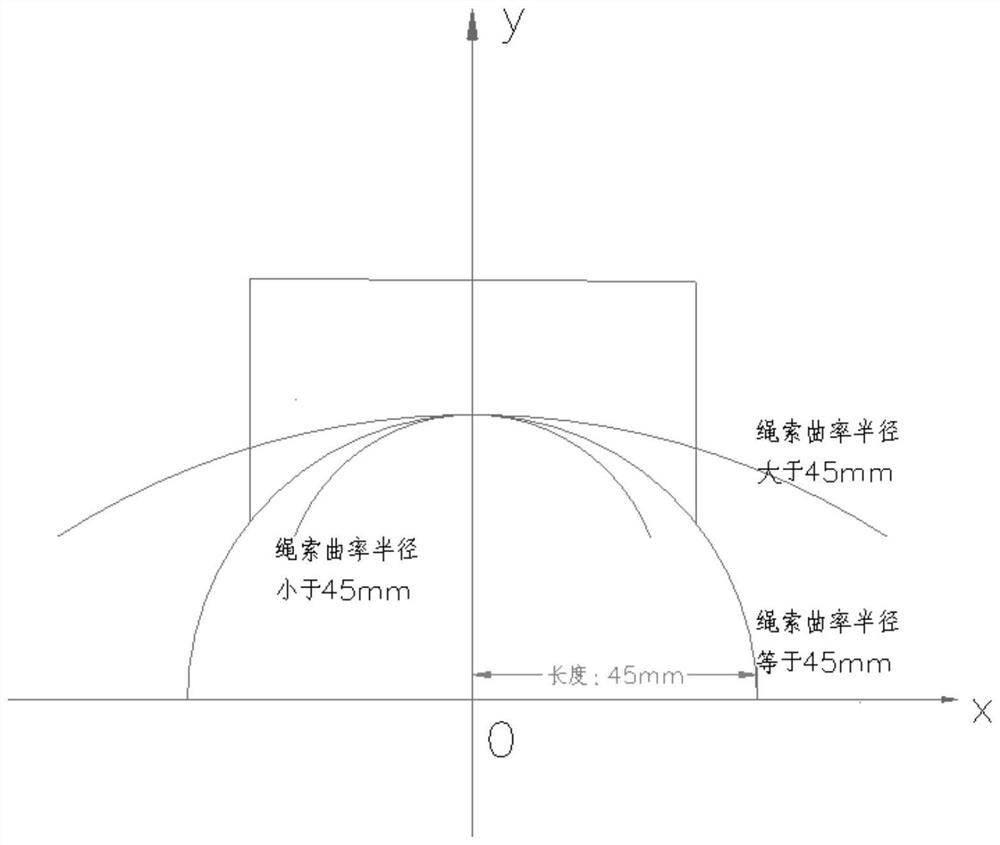

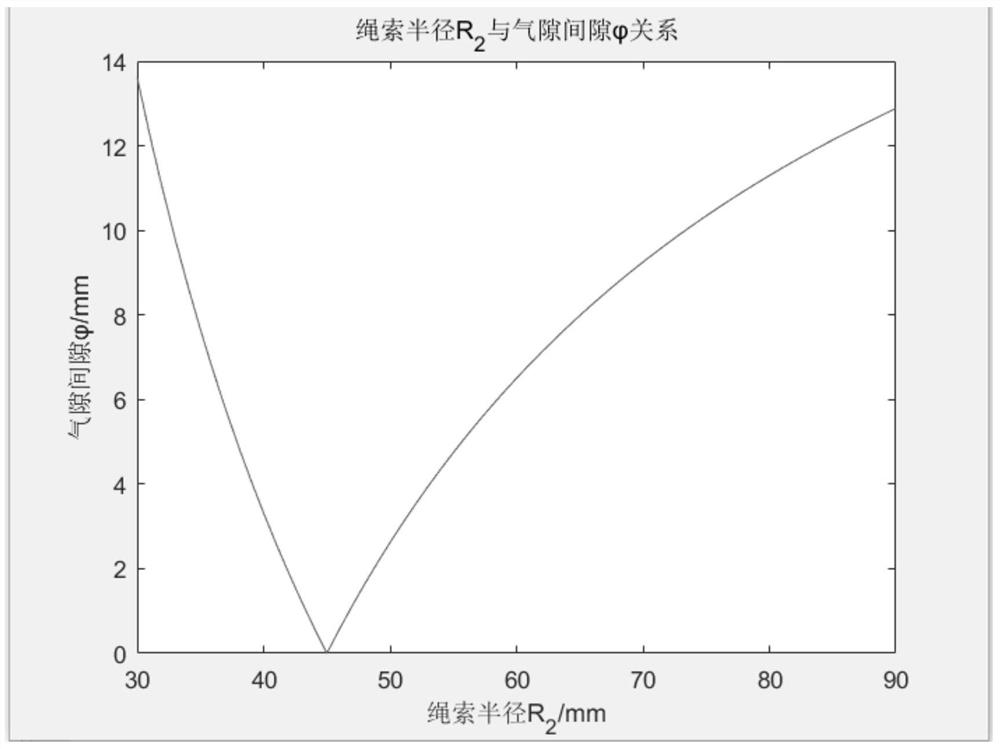

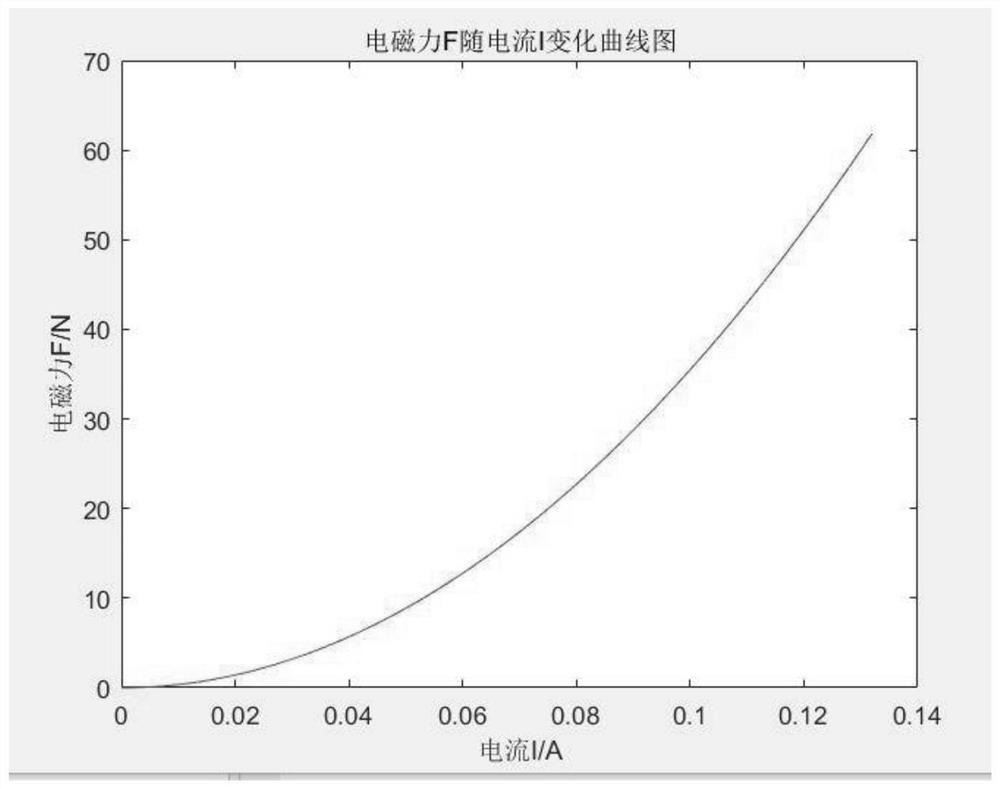

Electromagnetic force control method for magnetic adsorption cable climbing robot

PendingCN114839876AImprove immunityRealize online estimationBridge structural detailsAdaptive controlControl theoryMechanical engineering

The invention discloses an electromagnetic force control method for a magnetic adsorption cable climbing robot, and the method comprises the steps: taking the vibration of a bridge cable detection robot on a bridge cable as interference, and detecting the motion state of the robot through an attitude sensor; the magnetic adsorption robot moves on the inclined cable, if vibration occurs, an attitude sensor can detect an acceleration signal, an industrial personal computer reads an acceleration signal value, and then the voltage value of an output port is adjusted according to the signal value; and finally, the buck boosting module is used for amplifying the voltage value of the output port of the industrial personal computer and introducing the voltage value into two ends of the electromagnetic mechanism. A sliding mode control method is adopted to control the voltage of the output port of the industrial personal computer so as to control the current introduced into the coil of the electromagnetic mechanism. The robot can automatically select the most appropriate electromagnetic force for control according to the detected vibration signal.

Owner:NANJING UNIV OF POSTS & TELECOMM

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com