Marine frequency converter hoisting tool

A hoisting tool and frequency converter technology, which is applied to hoisting devices, portable hoisting devices, etc., can solve the problems of inconvenient use of hoisting tools, and achieve the effects of protecting cargo safety, improving stability and occupying a small area.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

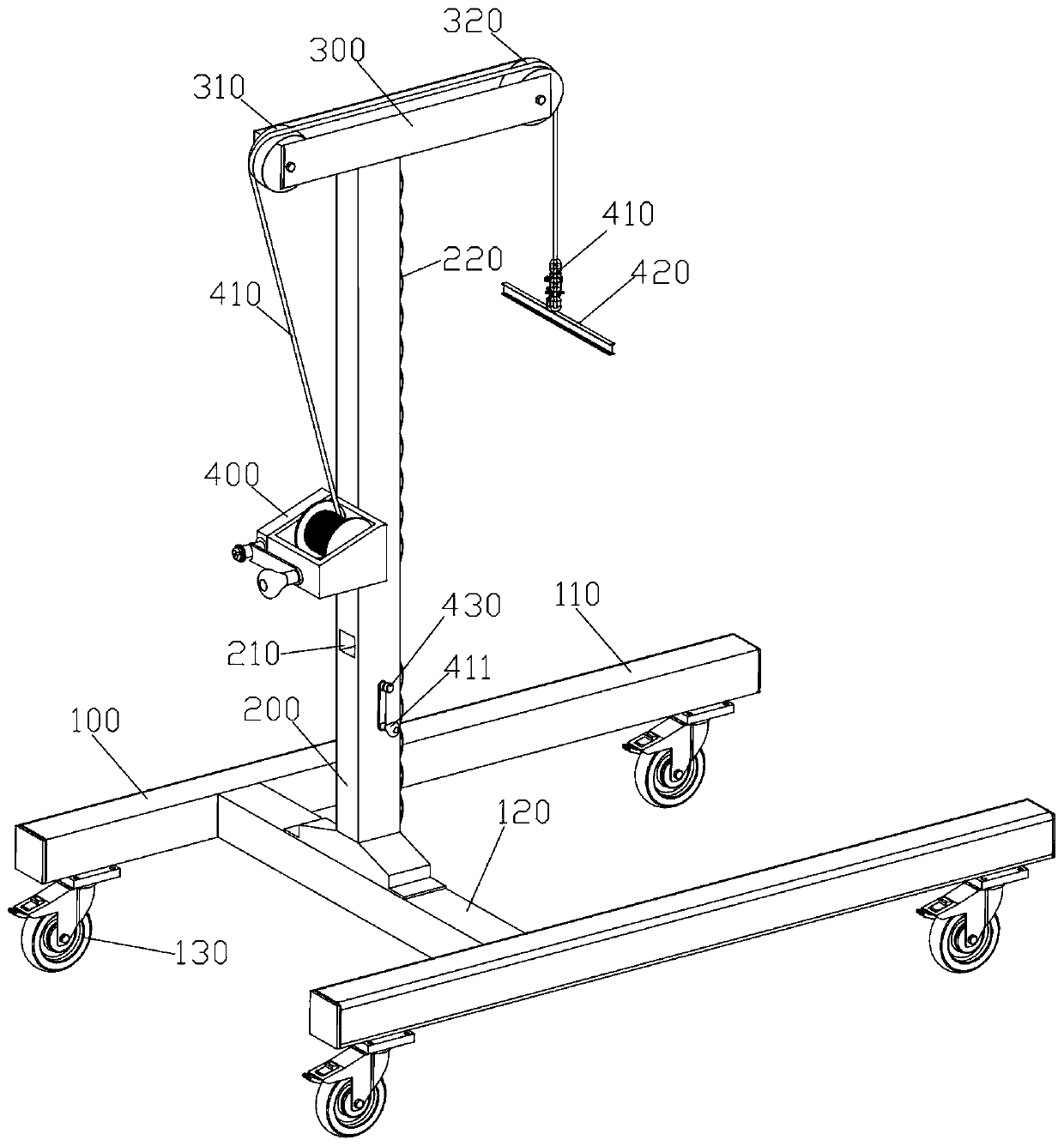

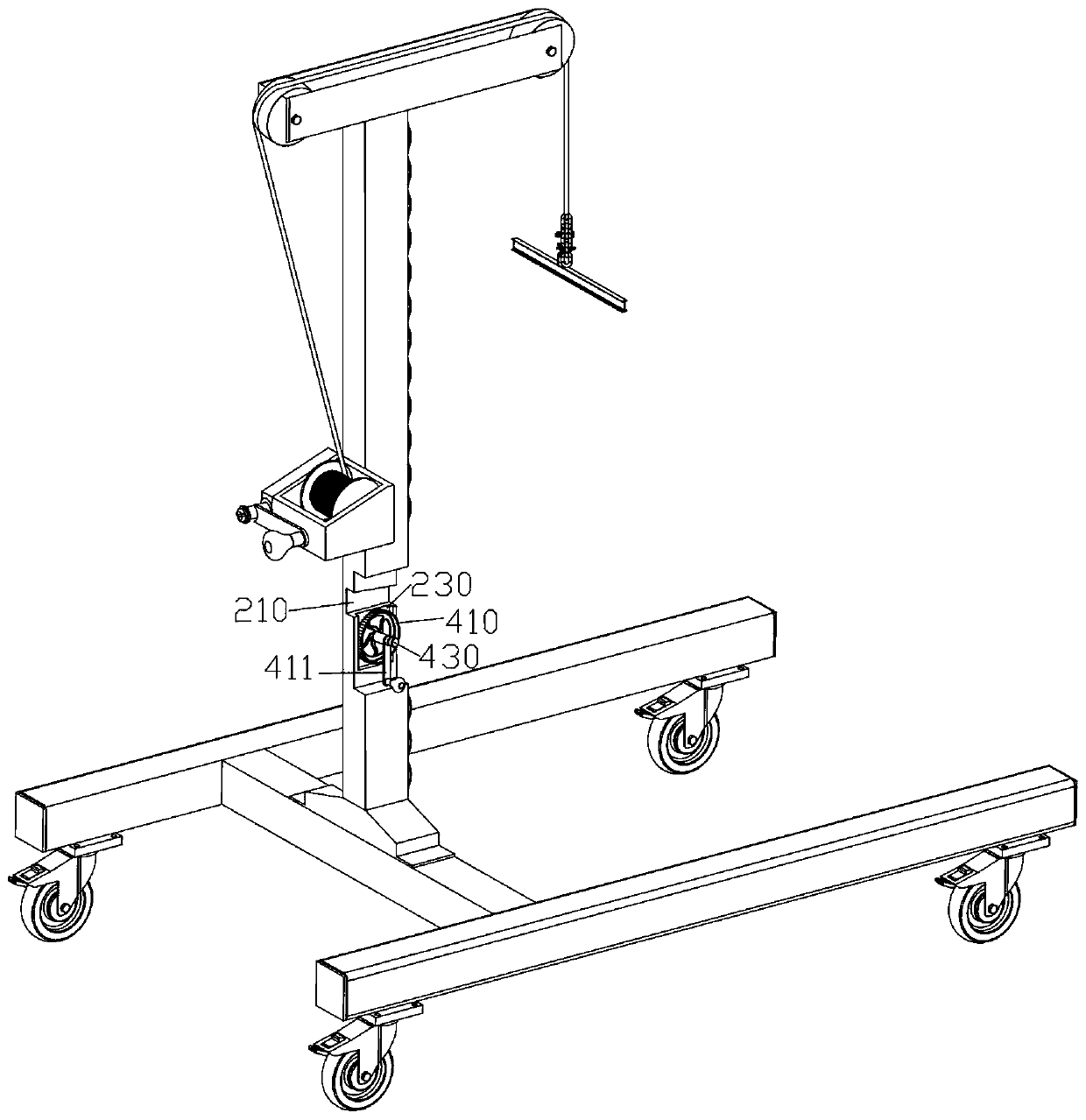

[0051] Such as Figure 1-8 As shown, the present invention provides a marine frequency converter hoisting tool. The base 100 is an H-shaped structure, including support beams 110 and middle beams 120 on both sides. The bottom of the base 100 is provided with moving wheels 130. Heavy-duty casters with brakes with a force of 300 kg, two directional and two swivel, allow the lifting tool to move freely or turn, and remain stable when stationary.

[0052] The load-bearing bracket 200 is longitudinally fixed on the base 100, specifically installed on the middle beam 120 of the H-shaped structure of the base 100, and the middle beam 120 is close to the tail of the H-shaped structure to balance the hoisting tool during the hoisting process. center of gravity.

[0053] A top beam 300 is horizontally arranged on the top of the load-bearing bracket 200, and the length direction of the top beam 300 is consistent with the length direction of the base 100. end.

[0054] The driving mech...

Embodiment 2

[0082] Such as Figure 9-11 As shown, on the basis of the first embodiment, the lifting function of the lifting tool itself is added.

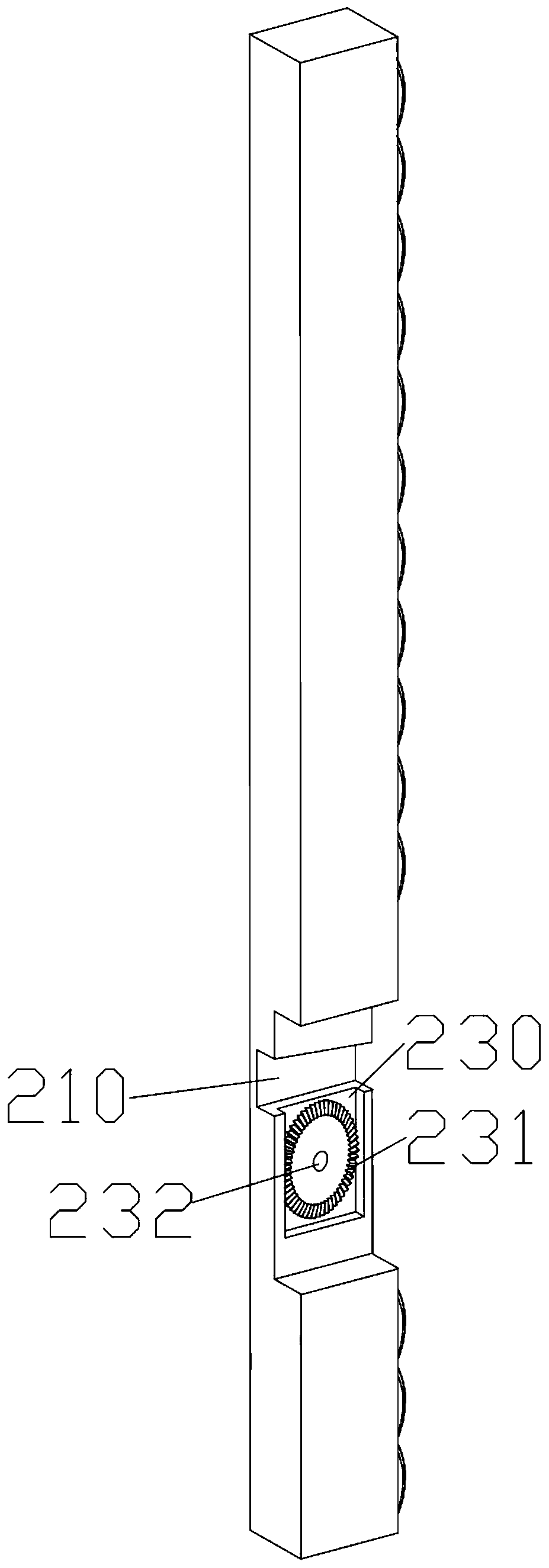

[0083] Under the premise of ensuring that the load-bearing bracket 200 has sufficient bearing capacity, the load-bearing bracket 200 at the upper end of the through hole 210 is a hollow structure, similar to a tubular structure, by analyzing the axial and radial force distribution of the square tube, etc., The material, performance and size of the materials used are all calculated to ensure sufficient bearing capacity without being too bulky and unbalanced, so that the hoisted heavy modules can move freely and safely in the small cabin.

[0084] A screw 610 is longitudinally arranged in the cavity of the load-bearing bracket 200, and the bottom of the screw 610 is rotatably mounted on the bottom of the cavity of the load-bearing bracket 200 through the second bearing 630, and a slider 620 is installed on the screw 610, thereby forming a The s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com