Disassembly and assembly device

A technology for equipment and disassembly and assembly of components, which is applied in the direction of lifting devices, lifting frames, workbenches, etc., can solve problems such as easy deformation and lack of support force, and achieve the goal of improving satisfaction, wide application range, and improving maintenance and disassembly efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

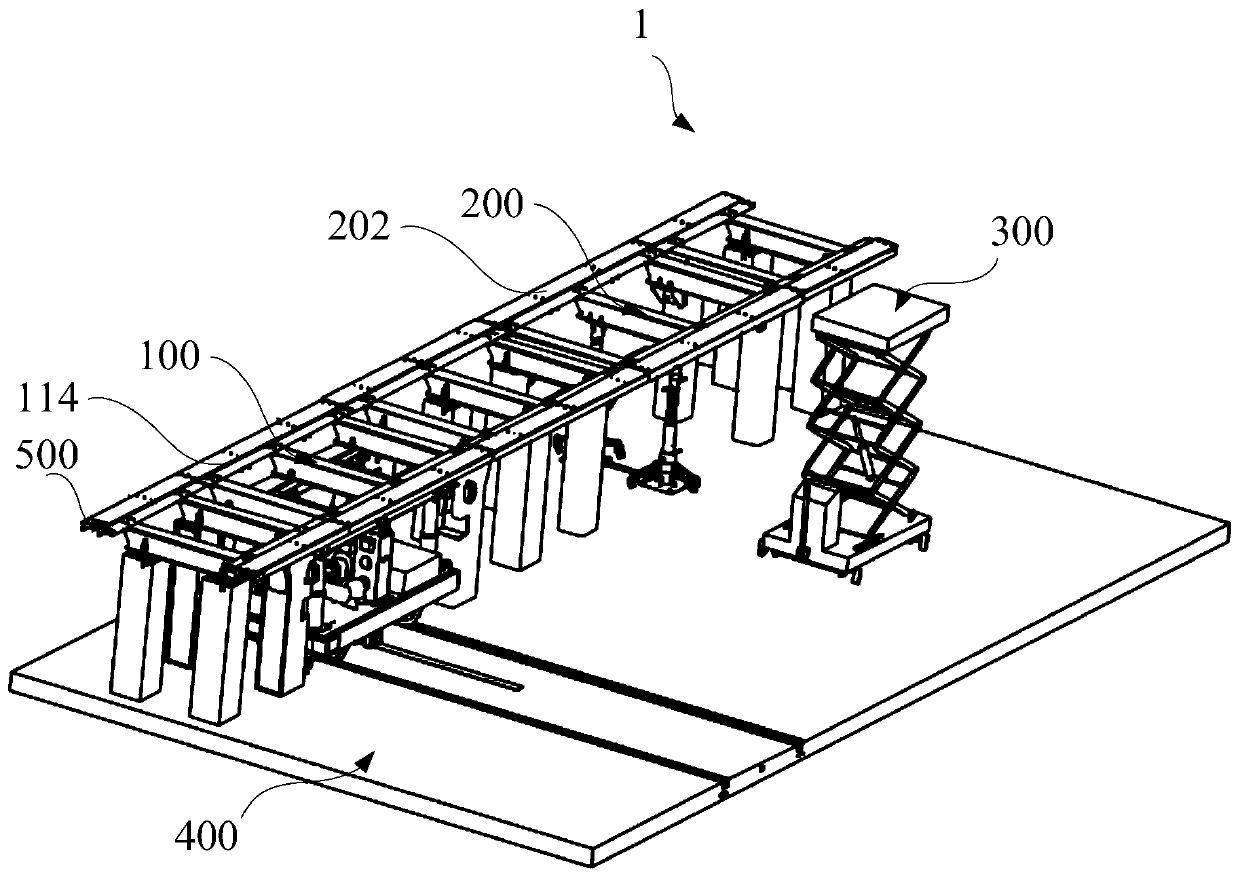

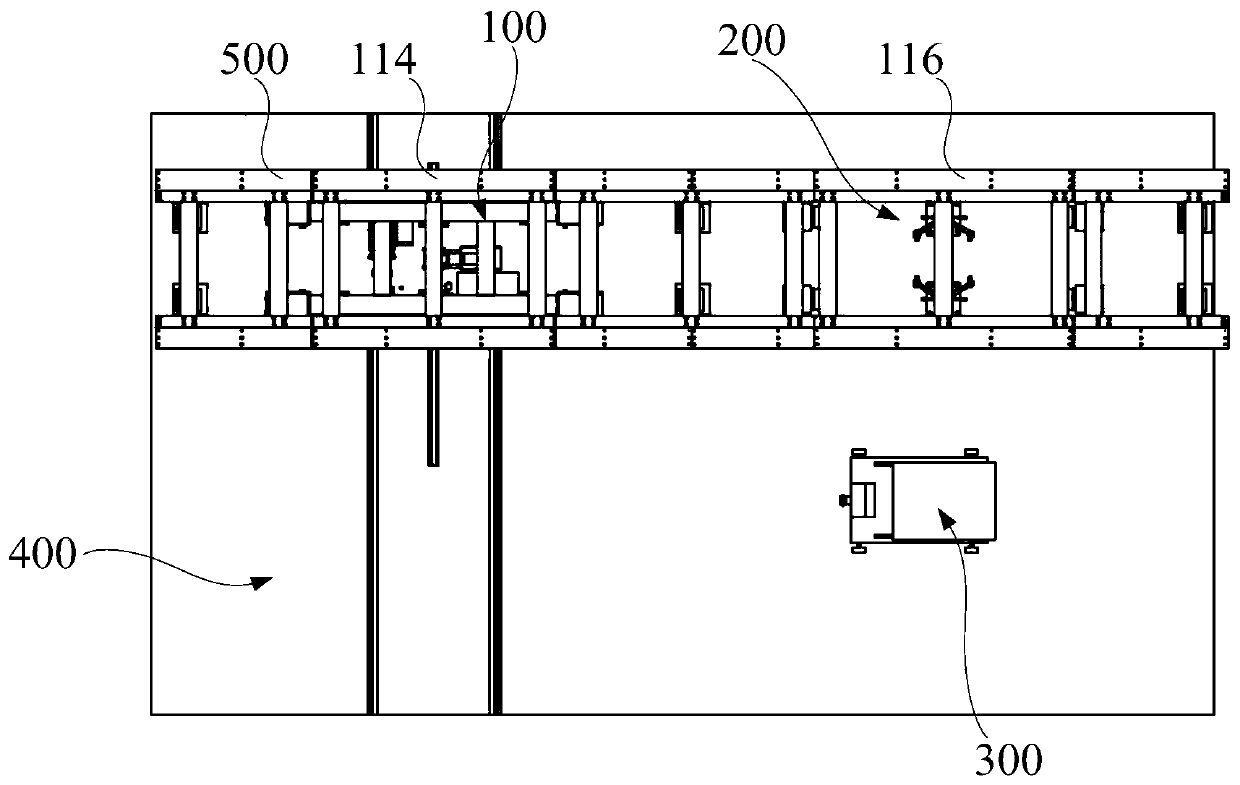

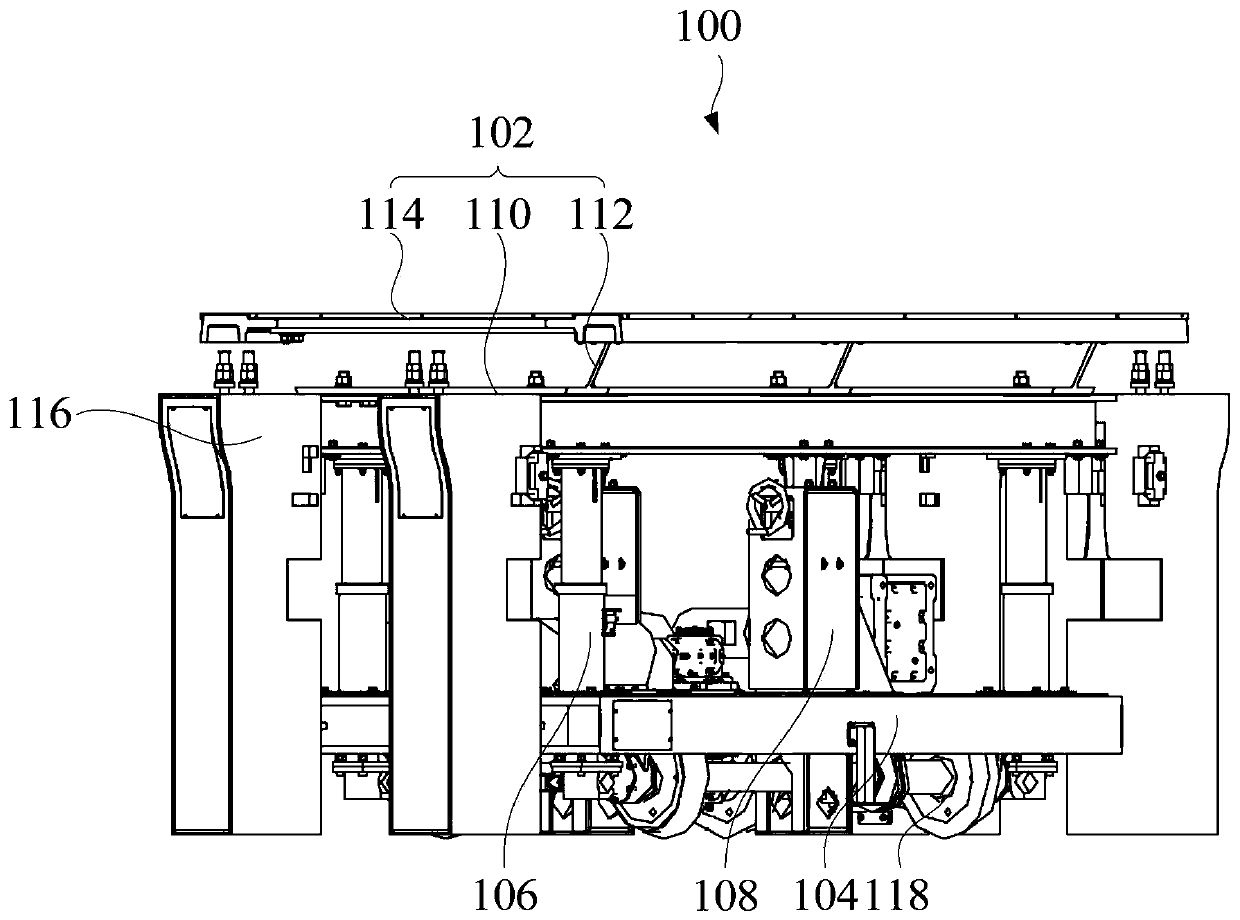

[0069] like Figure 1 to Figure 8 As shown, the embodiment of one aspect of the present invention proposes a disassembly equipment 1, including: a first support platform 102, a first support 104, a first lifting device 106, a second lifting device 108, wherein the first support 104 Located below the first support platform 102; the first lifting device 106 connects the first support platform 102 and the first support 104, and is configured to adjust the distance between the first support platform 102 and the first support 104; the second lift The device 108 is located on one of the first support platform 102 and the first support 104, and is located between the first support platform 102 and the first support 104. The second lifting device 108 is configured to be suitable for the first support platform 102 and the first support platform 102 The other one of the first brackets 104 abuts against each other; wherein, the first lifting device 106 is arranged on the edge of the firs...

Embodiment 2

[0073] like Figure 1 to Figure 8As shown, on the basis of the above-mentioned embodiment 1, further, the first support platform 102 includes: a first beam 110, two first beams 110 are arranged in parallel, along the length direction of the first beam 110, the first lifting device 106 Distributed on both sides of the second lifting device 108; the second beam 112 is connected with the first beam 110 and is located between the two first beams 110; the first track 114 is connected with the first beam 110 , and located on the side of the first beam 110 away from the first lifting device 106; the first column 116, the end of the first beam 110 is detachably connected to the first column 116.

[0074] In this example, image 3 and Figure 4 As shown, the first support platform 102 includes a first beam 110, a second beam 112, a first rail 114 and a first column 116, wherein the two first beams 110 are arranged in parallel, and the second beam 112 is opposite to the first beam 110...

Embodiment 3

[0078] like Figure 1 to Figure 8 As shown, on the basis of the above-mentioned embodiment 1 or embodiment 2, further, the first assembly and disassembly assembly 100 further includes: a first walking assembly 118 connected to the first bracket 104; a belt transmission assembly 120 arranged on the second A frame 104 is connected with the first traveling assembly 118 , and the belt transmission assembly 120 is configured to drive the first traveling assembly 118 .

[0079] In this example, image 3 and Figure 4 As shown, by connecting the first walking assembly 118 to the first support 104, the first walking assembly 118 can be moved to realize the horizontal movement of the suspension frame connected to the first beam 110, so as to move the suspension frame to a designated position. The belt transmission assembly 120 is located on the first support 104 and is connected with the first walking assembly 118. The driving speed of the first walking assembly 118 can be adjusted b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com