Novel car coupler tail frame conveyor for a wagon

A technology for railway wagons and coupler frames, applied in the field of electromechanical maintenance equipment for railway wagon maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

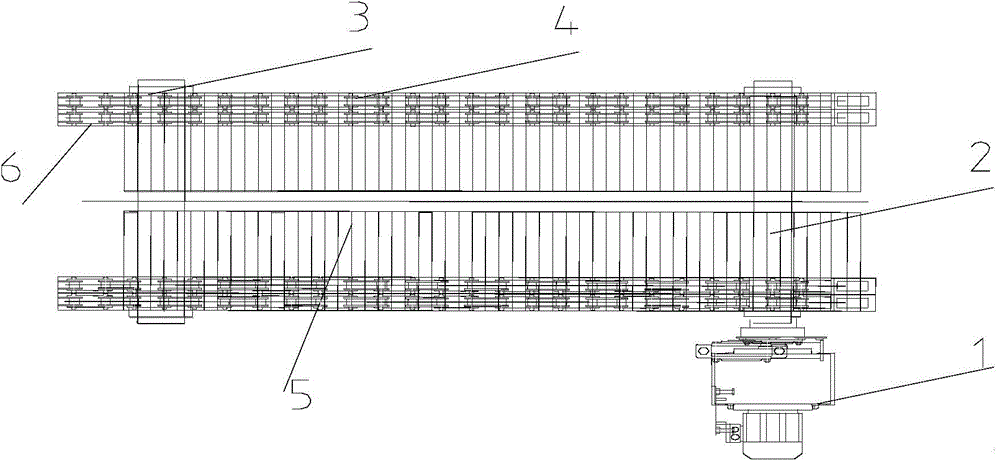

[0011] Embodiment 1 Composition of a railway wagon coupler and tail frame conveyor and the functions of its components:

[0012] The invention relates to a new coupler frame conveyor for railway freight cars. The coupler frame conveyor includes: motor reducer 1, driving sprocket 2, driven sprocket 3, chain 4, supporting chain row 5, and frame 6 components, characterized in that the coupler tail frame conveyor drives the drive sprocket 2 to run through the motor reducer 1, so that the coupler tail frame is transported along with the operation of the support chain row 5. Described chain 4 is four rows of roller chains. Described support chain row 5 is thick steel plate chain row.

Embodiment 2

[0013] Embodiment 2 The working process of a railway wagon coupler coupler frame conveyor:

[0014] The motor reducer 1 drives the driving sprocket 2 to rotate, the driven sprocket 3 runs together with the driving sprocket 2 under the drive of the chain 4, the supporting chain row 5 is installed on the roller chain of the chain 4, and follows the chain to make a straight line and circular motion. Hooktail frame placed in

[0015] Convey on the support chain row 5.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com