Rail wagon coupler overhauling conveying line

A technology for railway freight cars and conveying lines, which is applied to conveyors, mechanical conveyors, railway auxiliary equipment, etc., to achieve the effect of shortening the maintenance operation time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

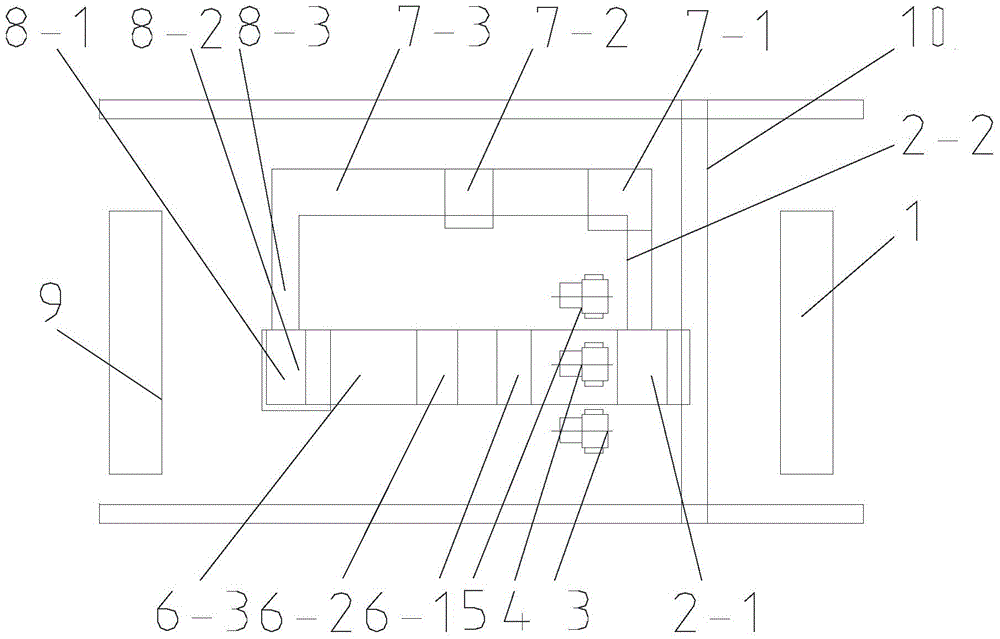

[0016] Embodiment 1 Composition of a railway freight car coupler overhaul conveyor line and the functions of its components:

[0017] The conveying line includes the storage rack for the complete set of couplers to be repaired 1, the coupler disassembly table 2, the hook lock iron conveying trolley 3, the knuckle tongue conveying trolley 4, the hook pushing iron conveying trolley 5, the coupler tail frame maintenance conveying line 6, the coupler coupler body maintenance conveying line 7. Coupler complete set assembly test bench 8. Assembled complete set of coupler storage rack 9, crane 10. It is characterized in that the above-mentioned railway freight car coupler maintenance conveyor line passes through the coupler tail frame maintenance conveyor line 6. Coupler coupler body maintenance conveyor line 7. Disassemble the components of the coupler and transport them to the component maintenance line for maintenance, and then assemble them in a complete set. The coupler disass...

Embodiment 2

[0018] Embodiment 2 The working process of a railway freight car coupler maintenance conveyor line:

[0019] Place the complete set of couplers to be repaired on the storage rack 1 of the complete set of couplers to be repaired by the forklift. When work is required, use the crane 10 to hoist it to the coupler disassembly table 2, disassemble the complete set of couplers on the coupler disassembly table 2, and disassemble the disassembled couplers. The cavity accessories hook lock iron, knuckle tongue and push iron are respectively placed in the hook lock iron conveying trolley 3, knuckle tongue conveying trolley 4, and hook push iron conveying trolley 5, and are pushed and transported to the special repairing station after being filled. The disassembled coupler frame enters the coupler frame overhaul conveyor line 6, and the coupler body enters the coupler body repair conveyor line 7, and after overhaul, the overhauled coupler frame and coupler body are assembled on the coup...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com